(>

0

0

0

0

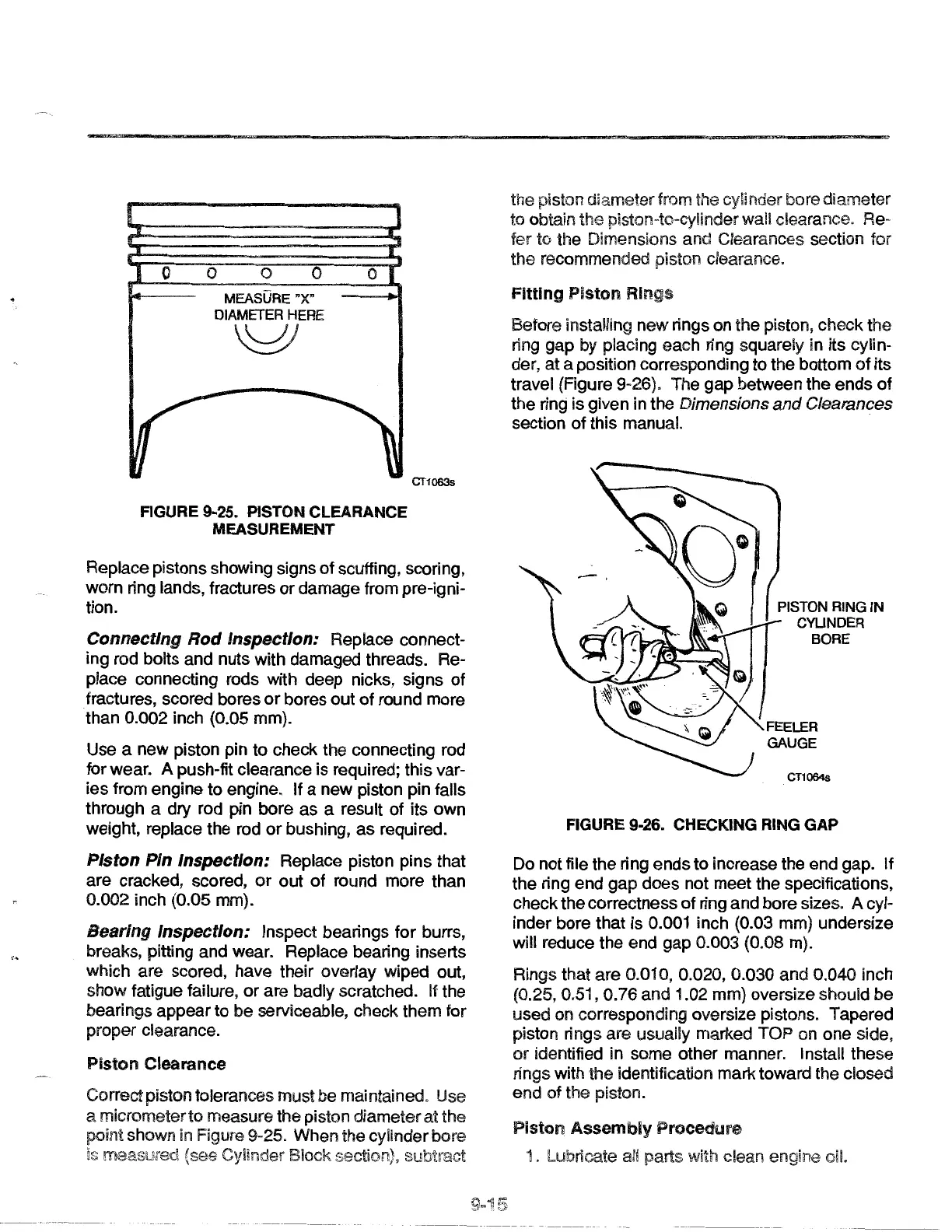

MEASURE "X"

DIAMETER HERE

'01

0

FIGURE 9-25. PISTON CLEARANCE

MEASUREMENT

CT1063s

Replace pistons showing signs

of

scuffing, scoring,

worn ring lands, fractures

or

damage from pre-igni-

tion.

Connecting Rod Inspection: Replace connect-

ing rod bolts and nuts with damaged threads. Re-

place connecting rods with deep nicks, signs

of

fractures, scored bores

or

bores out of round more

than

0.002 inch (0.05 mm).

Use a new piston pin

to

check the connecting rod

for wear.

A push-fit clearance is required; this var-

ies from engine to engine. If a new piston pin falls

through a

dry

rod pin bore

as

a result of its own

weight, replace the rod

or

bushing,

as

required.

Piston Pin Inspection: Replace piston pins that

are cracked, scored,

or

out

of

round more than

0.002 inch (0.05 mm).

Bearing Inspection: Inspect bearings for burrs,

breaks, pitting and wear. Replace bearing inserts

which are scored, have their overlay wiped out,

show fatigue failure, or are badly scratched.

If

the

bearings appear to be serviceable, check them for

proper clearance.

Piston Clearance

Correct piston tolerances must be maintained. Use

a micrometer to measure the piston diameter at the

point shown

in Figure 9-25. When the cylinder bore

is (see Cylinder Block section),

-

'"

'<::.&

the piston diameter from the cylinder bore diameter

to obtain the piston-to-cylinder wall clearance. Re-

fer

to the Dimensions and Clearances section for

the recommended piston clearance.

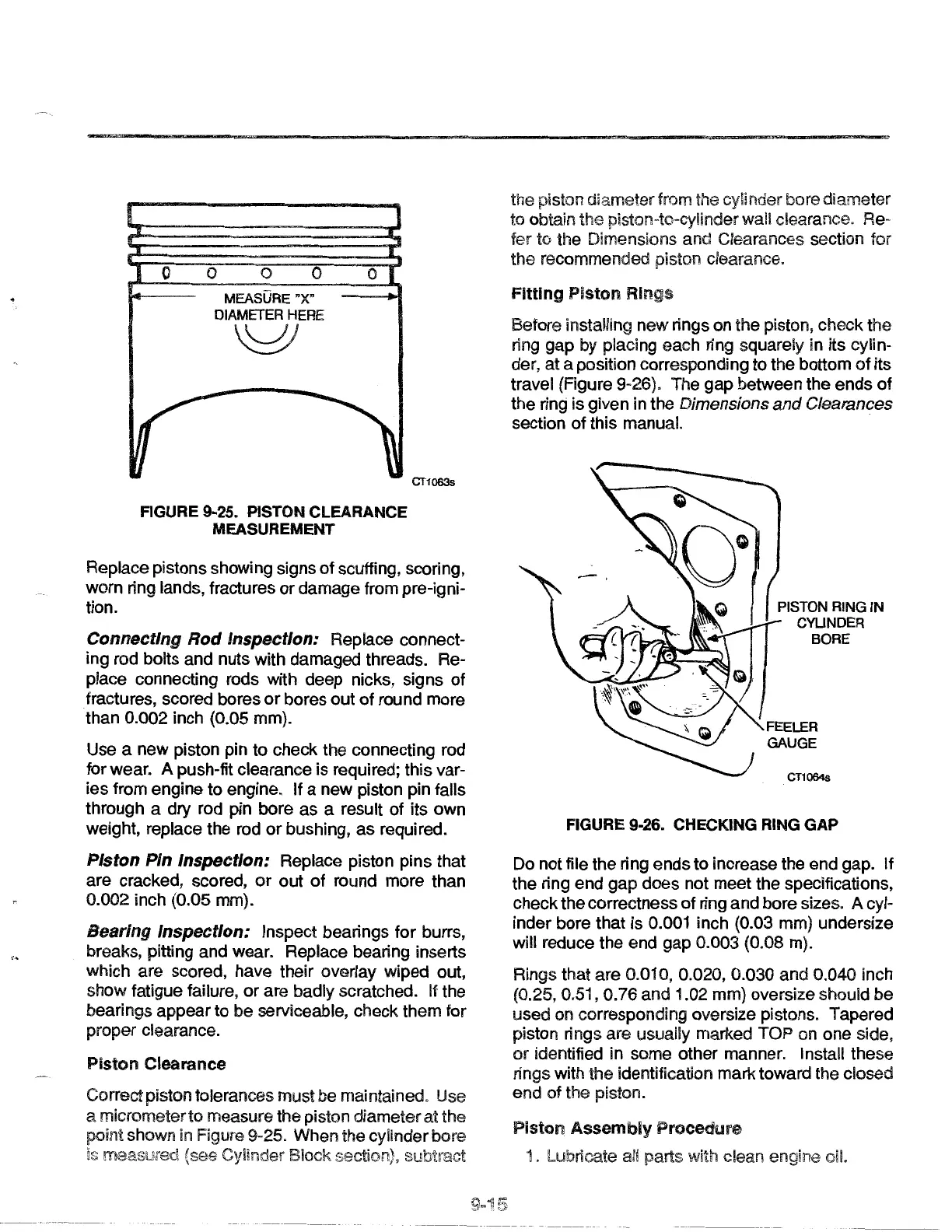

Fitting Piston Rings

Before installing new rings on the piston, check the

ring gap by placing each ring squarely in its cylin-

der, at a position corresponding to the bottom

of

its

travel (Figure

9-26). The gap between the ends

of

the ring is given in the Dimensions

and

Clearances

section

of

this manual.

PISTON RING IN

CYUNDER

BORE

CT1064s

FIGURE 9-26. CHECKING RING

GAP

Do not file the ring ends to increase the end gap. If

the ring end gap does not meet the specifications,

check the correctness

of

ring and bore sizes.

Acyl-

inder bore that is 0.001 inch (0.03 mm) undersize

will reduce the end gap

0.003 (0.08 m).

Rings that are

0.01 0, 0.020, 0.030 and 0.040 inch

(0.25, 0.51, 0.76 and 1.02 mm} oversize should be

used on corresponding oversize pistons. Tapered

piston rings are usually marked TOP on one side,

or

identified in some other manner. Install these

rings with

the identification mark toward the closed

end of the piston.

Piston

Assembly Procedure

1. Lubricate all parts with clean engine oil.

Loading...

Loading...