CYLINDER COMPRESSION TEST

Examining the spark plugs and testing cylinder

compression can tell much about the condition of

the

valves, piston rings and cylinders. Test cylinder

compression as follows:

1.

Start the genset and let it warm up.

2. Stop the genset and

remove and inspect the

spark plugs. See IGNITION SYSTEM in this

section.

3. Insert the compression gauge nozzle into one

of the spark plug holes, hold the throttle open

and crank the engine. Note the pressure indi-

cated

by

the gauge.

4.

Repeat the test on the other cylinder.

5.

Refer to Section

9.

Engine Block Assembly if

cylinder compression test pressures do not

meet

Specifications.

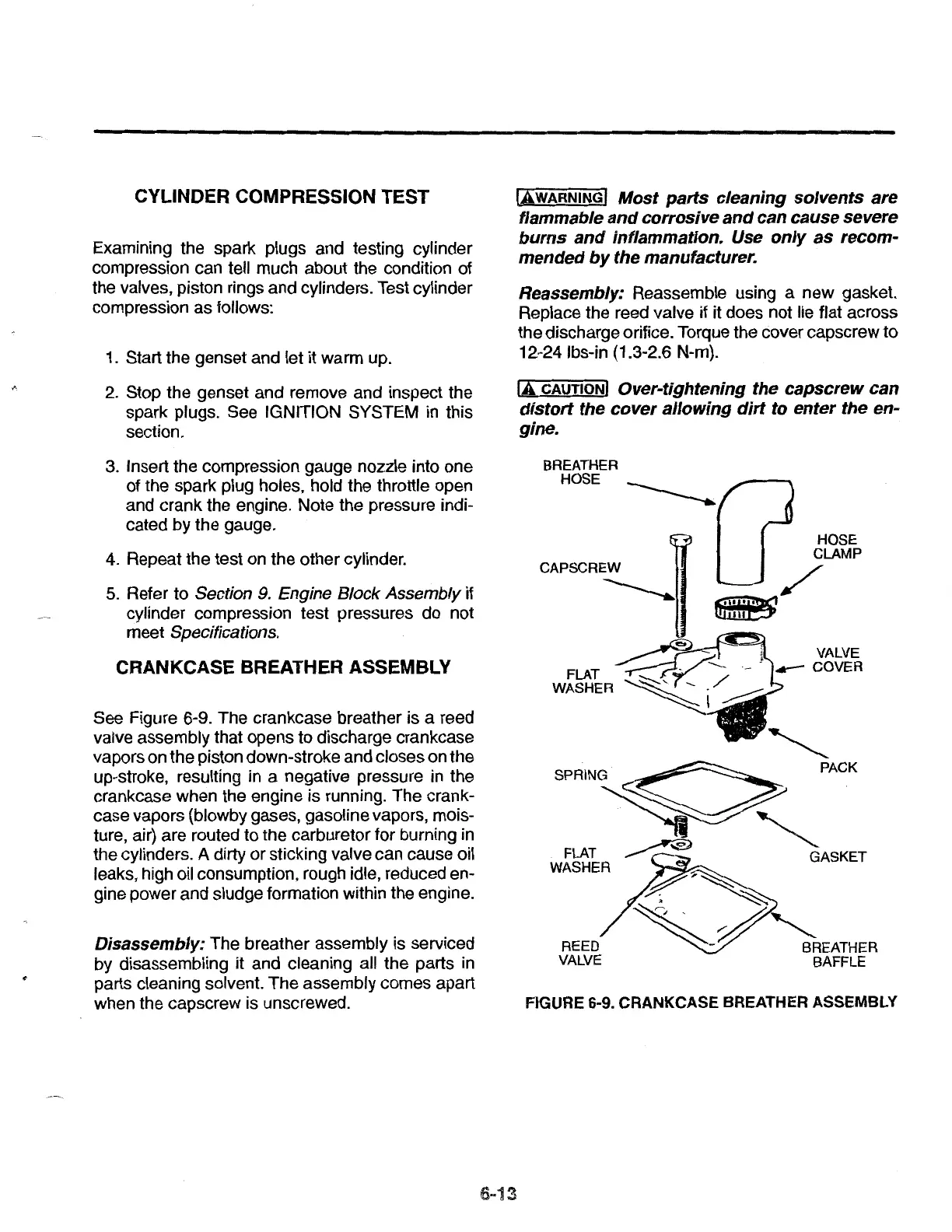

CRANKCASE BREATHER ASSEMBLY

See Figure 6-9. The crankcase breather is a reed

valve assembly that opens to discharge crankcase

vapors on the piston down-stroke and closes on the

up-stroke, resulting

in

a negative pressure in the

crankcase when the engine is running. The crank-

case vapors (blowby gases, gasoline vapors, mois-

ture, air) are routed to the carburetor for burning in

the cylinders. A dirty or sticking

valve can cause oil

leaks, high oil consumption, rough idle, reduced en-

gine power and sludge formation within the engine.

Disassembly: The breather assembly is serviced

by disassembling it and cleaning all the parts

in

parts cleaning solvent. The assembly comes apart

when the capscrew is unscrewed.

6-13

14wARNINGI

Most

parts

cleaning

solvents

are

flammable

and

corrosive

and

can cause severe

burns

and

inflammation. Use

only

as

recom-

mended

by

the manufacturer.

Reassembly:

Reassemble using a new gasket.

Replace the reed

valve if it does not lie flat across

the discharge orifice. Torque the

cover capscrew to

12-241bs-in (1.3-2.6 N-m).

14

CAUTION! Over-tightening the

capscrew

can

distort

the

cover

allowing

dirt

to

enter

the en-

gine.

BREATHER

HOSE

FLAT

WASHER

FLAT

WASHER

REED

VALVE

HOSE

CLAMP

/

~

Ill

VALVE

COVER

PACK

GASKET

~~

~#'

-

BREATHER

BAFFLE

FIGURE 6-9. CRANKCASE BREATHER ASSEMBLY

Loading...

Loading...