against the bearing plate, and the flat surtace

of

the thrust washer goes against the shim.

6. Place the new bearing plate gasket in position

on the block, making sure the oil hole on the

back

of the block is exposed.

7. Install the rear bearing plate and fasten with

two

nuts (orcapscrews) tightened to the speci-

fied torque. Make sure the rear thrust washer

and shim(s} did not slip out

of

place during in-

stallation. The crankshaft should turn freely by

hand.

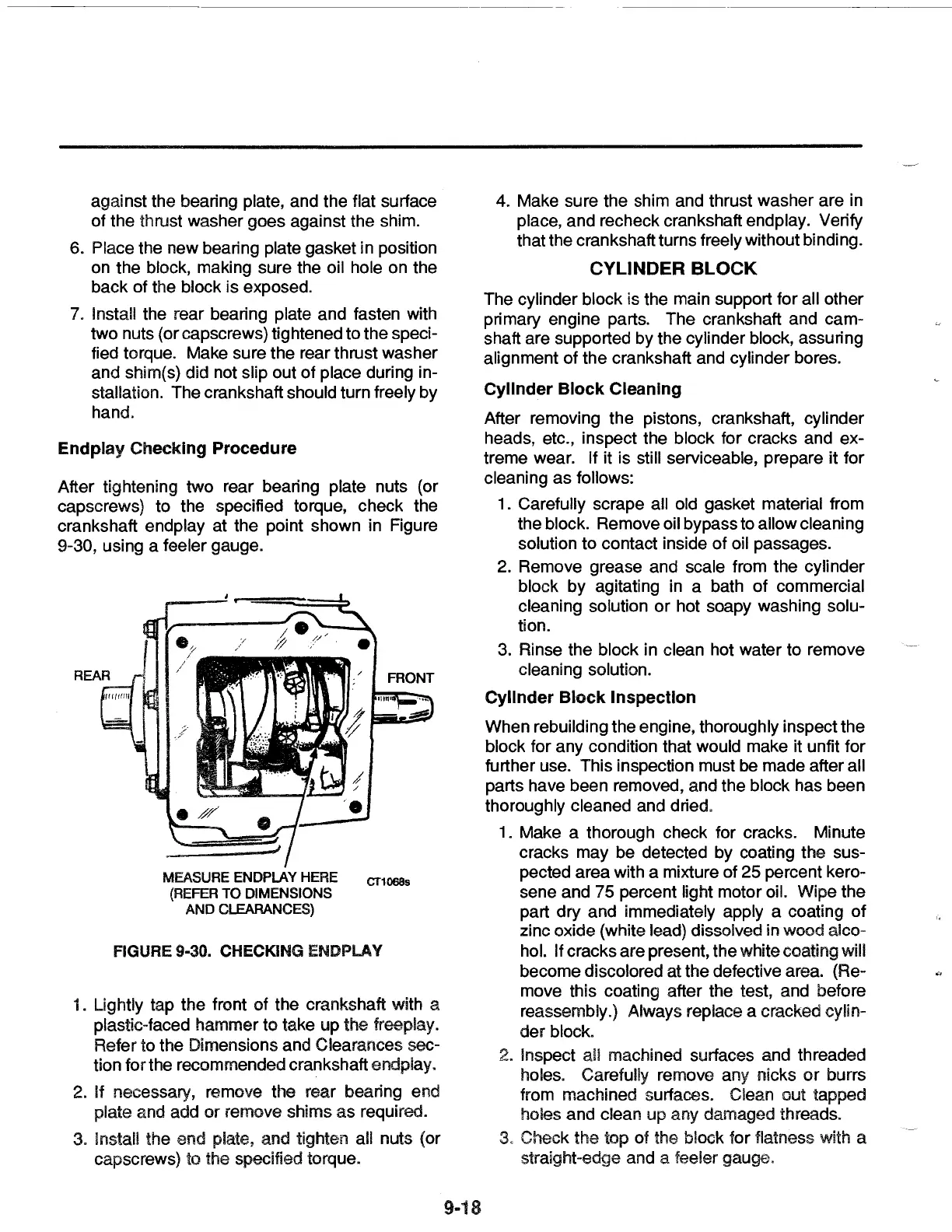

Endplay Checking Procedure

After tightening two rear bearing plate nuts (or

capscrews) to the specified torque, check the

crankshaft endplay at the point shown in Figure

9-30, using a feeler gauge.

MEASURE ENDPLAY HERE

(REFER

TO

DIMENSIONS

AND CLEARANCES)

CT1068s

FIGURE 9-30. CHECKING ENDPLA Y

1 . Lightly tap the front

of

the crankshaft with a

plastic-faced hammer to take up the freeplay.

Refer to the Dimensions and Clearances sec-

tion for the recommended crankshaft endplay.

2. If necessary, remove the rear bearing end

plate and add

or

remove shims

as

required.

3. install the end plate, and tighten all nuts (or

capscrews) to the specified torque.

9-18

4. Make sure the shim and thrust washer are in

place, and recheck crankshaft endplay. Verify

that the crankshaft turns freely without binding.

CYLINDER BLOCK

The cylinder block is the main support for all other

primary engine parts. The crankshaft and cam-

shaft are supported by the cylinder block, assuring

alignment of the crankshaft and cylinder bores.

Cylinder

Block

Cleaning

After removing the pistons, crankshaft, cylinder

heads, etc., inspect the block for cracks and ex-

treme wear.

If it is still serviceable, prepare it for

cleaning

as

follows:

1 . Carefully scrape all old gasket material from

the block. Remove oil bypass to allow cleaning

solution to contact inside

of

oil passages.

2. Remove grease and scale from the cylinder

block

by

agitating in a bath

of

commercial

cleaning solution

or

hot soapy washing solu-

tion.

3. Rinse the block in clean hot water to remove

cleaning solution.

Cylinder

Block

Inspection

When rebuilding the engine, thoroughly inspect the

block for any condition that would make it unfit for

further use. This inspection must be made after all

parts have been removed, and the block has been

thoroughly cleaned and dried.

1. Make a thorough check for cracks. Minute

cracks

may

be detected by coating the sus-

pected area with a mixture of 25 percent kero-

sene and 75 percent light motor oil. Wipe the

part dry and immediately apply a coating

of

zinc oxide (white lead) dissolved in wood alco-

hol.

If cracks are present, the white coating will

become discolored at the defective area. (Re-

move this coating after the test, and before

reassembly.) Always replace a cracked

cylin-

der

block.

2.

Inspect all machined surtaces and threaded

holes. Carefully remove any nicks

or

burrs

from machined surtaces. Clean

out tapped

holes and clean

up

any damaged threads.

3. Check the top of the block for flatness with a

straight-edge and a feeler gauge.

Loading...

Loading...