-----

-------------

-------

---

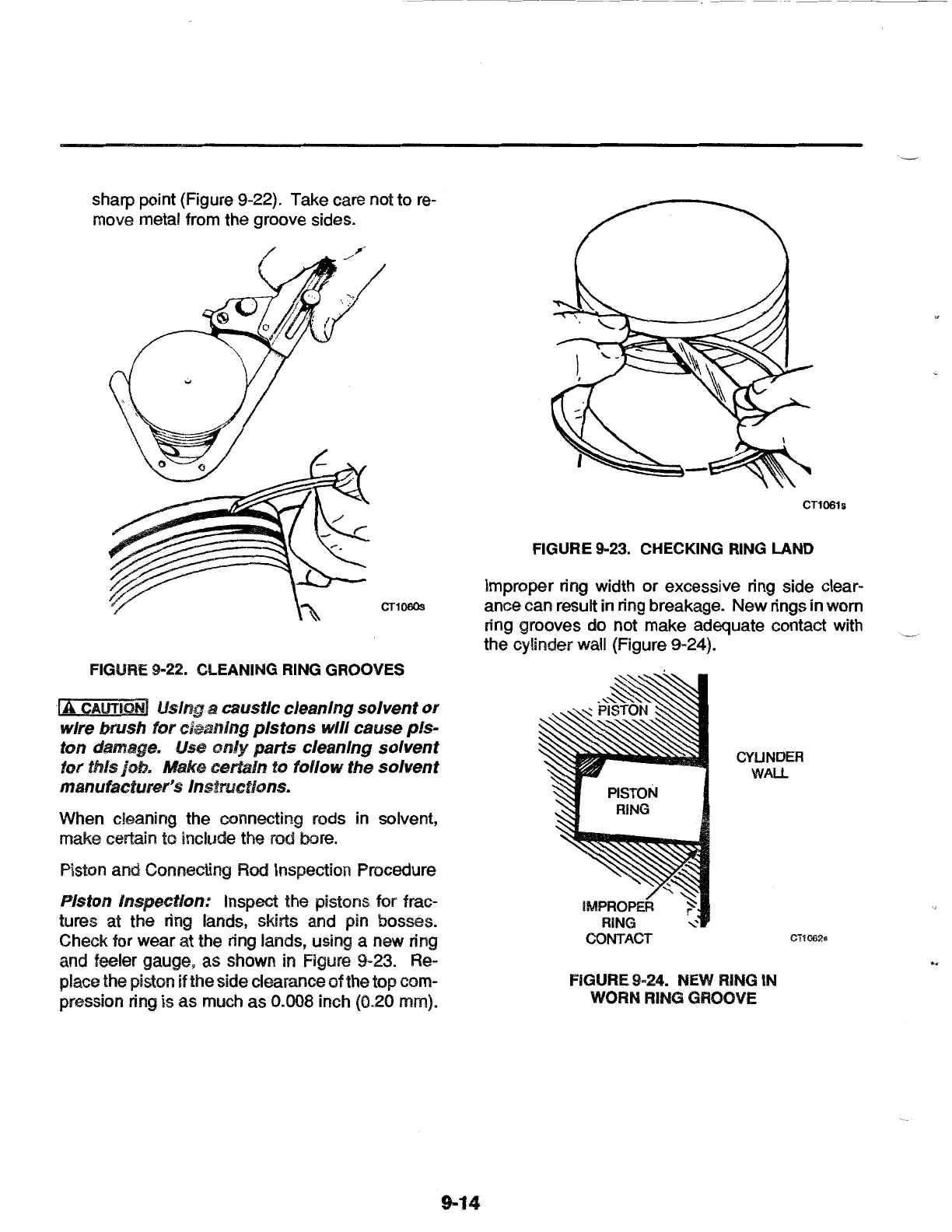

sharp point (Figure 9-22). Take care not

tore-

move metal from the groove sides.

CT1061s

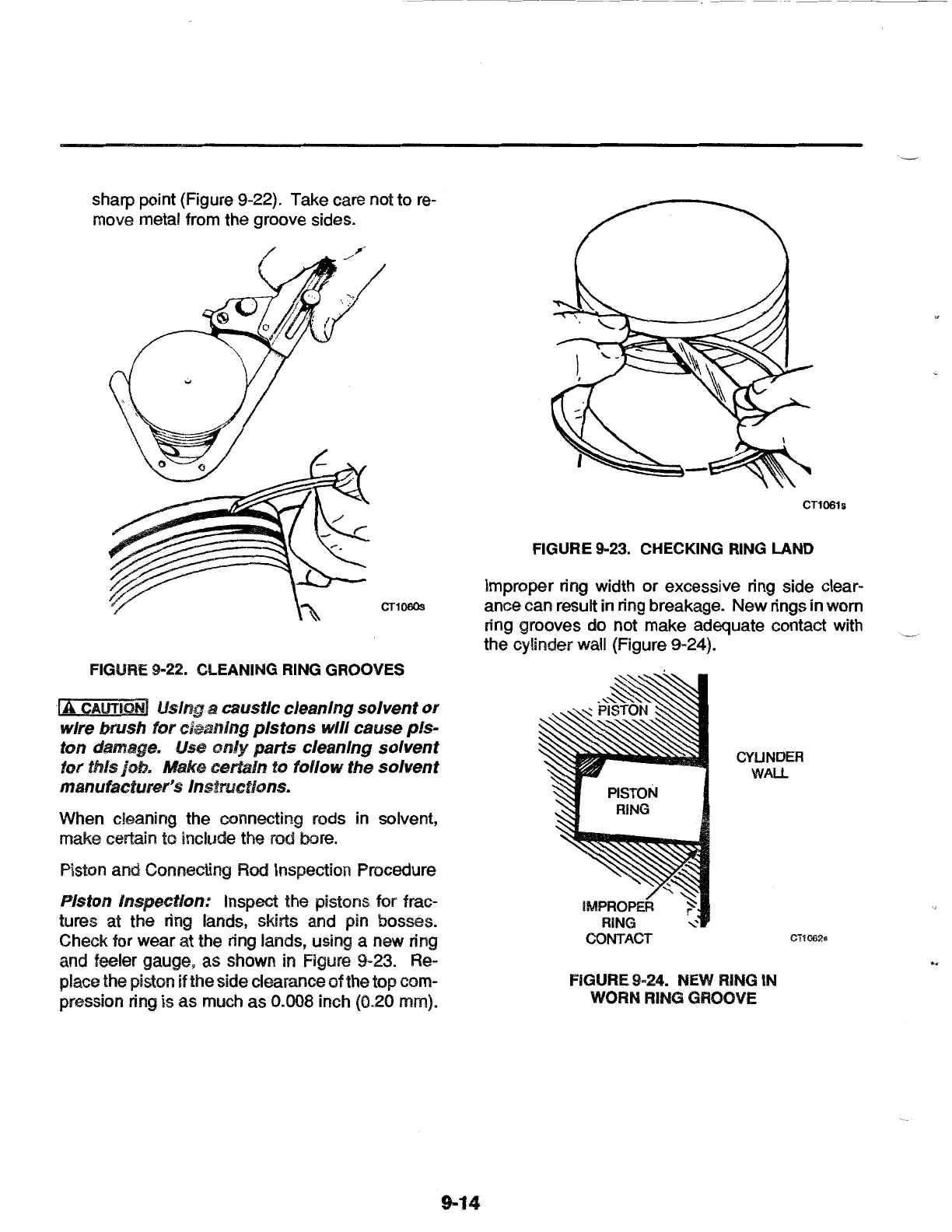

FIGURE 9-23. CHECKING RING LAND

Improper ring width or excessive ring side clear-

cnOGOs

ance can result in ring breakage. New rings in worn

ring grooves do not make adequate contact with

the cylinder wall (Figure 9-24).

FIGURE 9-22. CLEANING RING GROOVES

lA CAUTION! Using a caustic cleaning

solvent

or

wire

brush

for

cleaning

pistons

will

cause

pis-

ton damage. Use

only

parts

cleaning

solvent

for

this job. Make certain

to

follow

the

solvent

manufacturer's Instructions.

When cleaning the connecting rods in solvent,

make certain to include the rod bore.

Piston and Connecting

Rod

Inspection Procedure

Piston Inspection: Inspect the pistons for frac-

tures at the ring lands, skirts and pin bosses.

Check for wear

at

the ring lands, using a new ring

and feeler gauge, as shown in Figure 9-23. Re-

place the piston

if

the side clearance

of

the top com-

pression ring is

as

much as 0.008 inch (0.20 mm).

9-14

CYUNDER

WALL

FIGURE

9G24.

NEW RING IN

WORN RING GROOVE

CT1062s

Loading...

Loading...