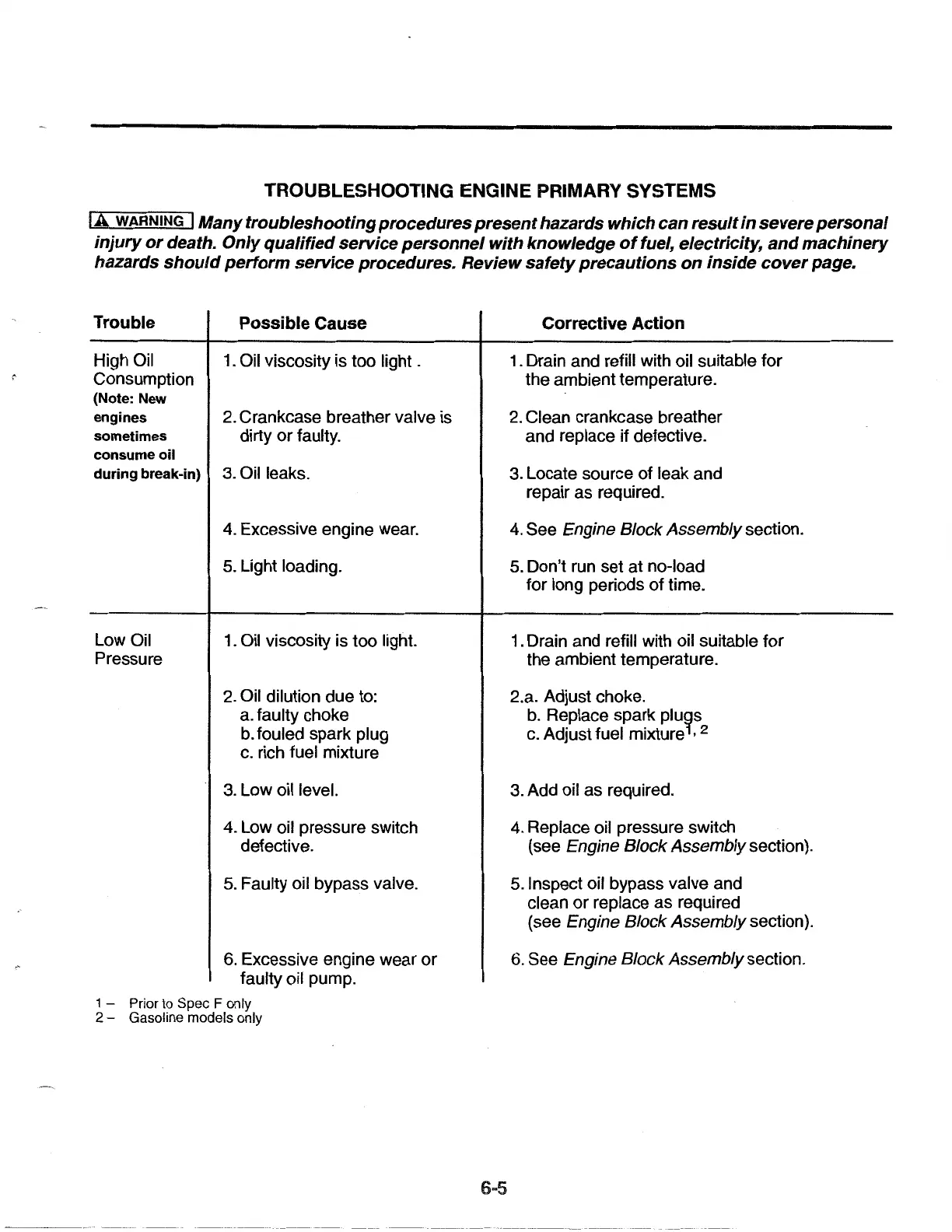

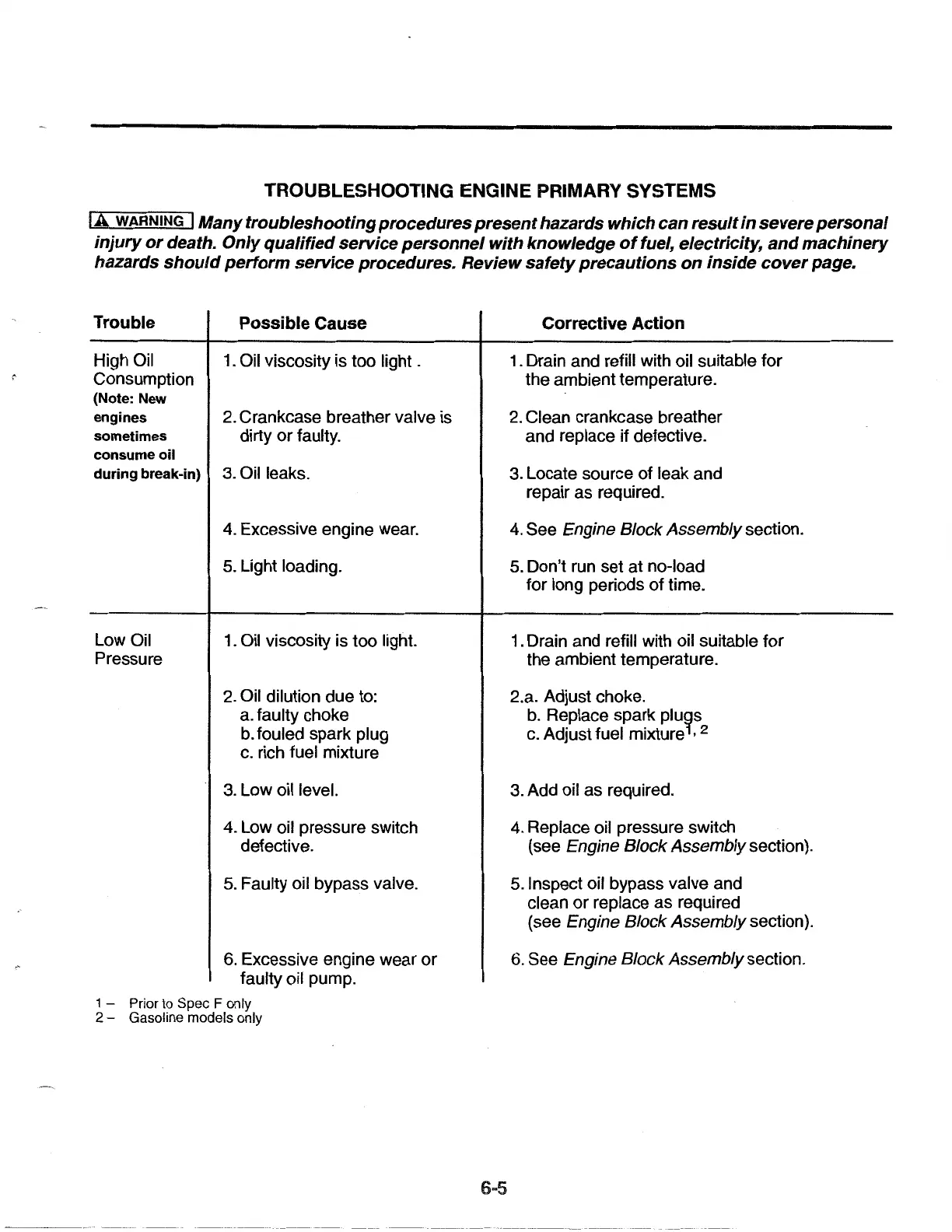

TROUBLESHOOTING ENGINE PRIMARY SYSTEMS

lA

WARNING I Many troubleshooting procedures present hazards which can result

in

severe personal

injury

or

death.

Only

qualified service personnel with knowledge

of

fuel, electricity,

and

machinery

hazards

should

perform

service procedures. Review safety precautions

on

inside

cover

page.

Trouble Possible Cause

High Oil

1.

Oil viscosity is too light .

Consumption

(Note: New

engines

2. Crankcase breather valve is

sometimes dirty

or

faulty.

consume

oil

during

break-in)

3.

Oil leaks.

Low Oil

Pressure

4.

Excessive engine wear.

5.

Light loading.

1.

Oil viscosity is too light.

2.

Oil dilution due to:

a. faulty choke

b.

fouled spark plug

c.

rich fuel mixture

3.

Low oil level.

4. Low oil pressure switch

defective.

5.

Faulty oil bypass valve.

6.

Excessive engine wear or

faulty oil pump.

1 - Prior to Spec F only

2 - Gasoline models only

6-5

Corrective Action

1.

Drain and refill with oil suitable for

the ambient temperature.

2.

Clean crankcase breather

and replace if defective.

3. Locate source of leak and

repair as required.

4.

See Engine Block Assembly section.

5.

Don't run set

at

no-load

for long periods of time.

1.

Drain and refill with oil suitable for

the ambient temperature.

2.a. Adjust choke.

b. Replace spark

plu~s

c.

Adjust fuel mixture · 2

3.

Add oil as required.

4.

Replace oil pressure switch

(see Engine Block Assembly section).

5.lnspect oil bypass valve and

clean or replace as required

(see Engine Block Assembly section).

6.

See Engine Block Assembly section.

Loading...

Loading...