...

2. Push the governor rod gently

towa~ds

the car-

buretor (full-throttle position). While keeping it

there, turn the socket, as necessary, to

lengthen

or

shorten the rod so that the ball and

socket line up.

Iii

CAUTION! Too

much

pressure

on

the

rod

can

result

in

a

faulty

adjustment

of

the

rod

length.

3.

Snap the socket back over the ball.

4.

Tighten the lock nut while holding the socket

square with the axis of the ball. Also, the leg at

the throttle end of the rod must be kept level.

5.

Gently rotate the governor arm and check for

binding. If necessary, loosen the locknut and

repeat Step 4 until the linkage moves smoothly.

Binding can cause erratic governor action.

Note: The

following

groups

of

adjustments

must

be

performed

in

sequence.

They

apply

to

Spec A only.

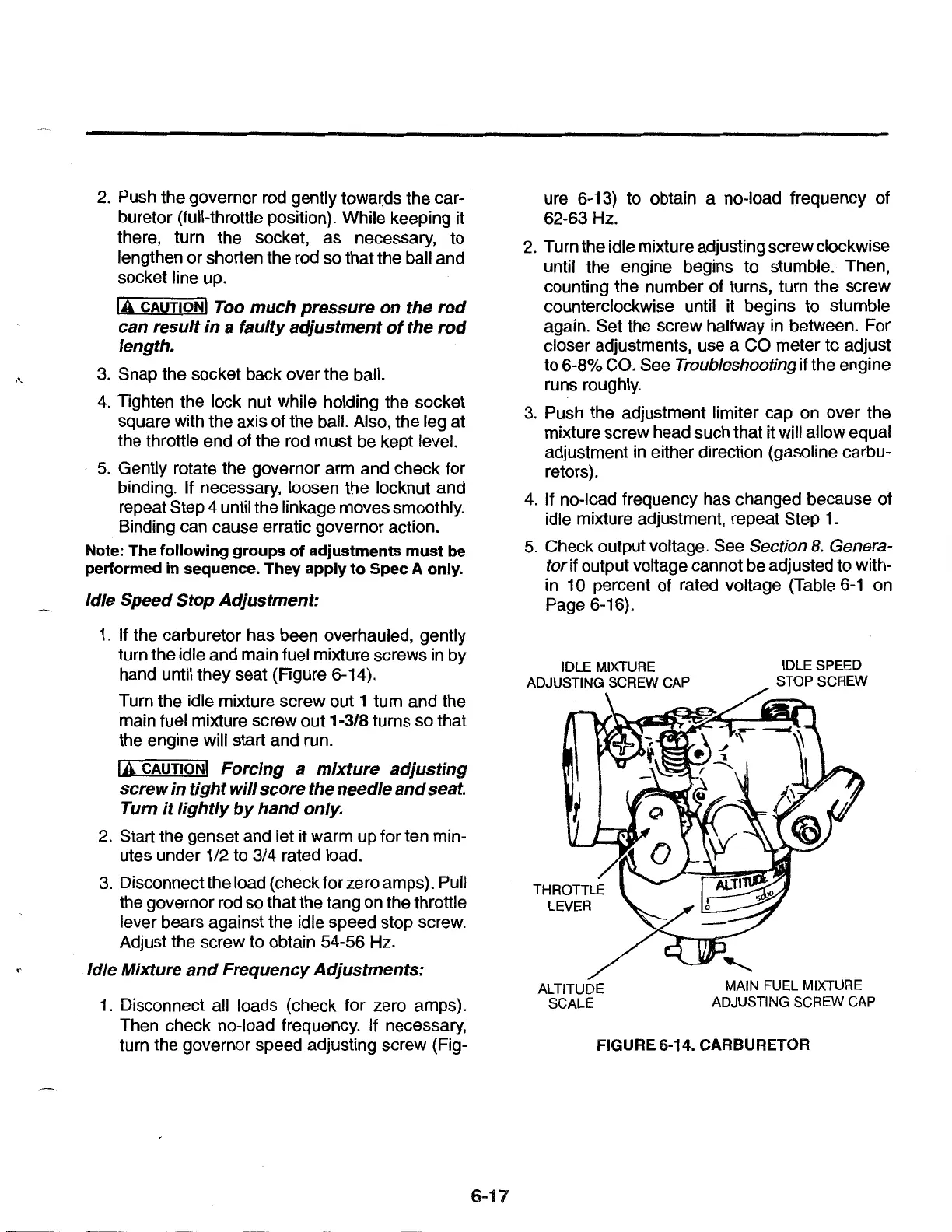

Idle Speed

Stop

Adjustment:

1.

If the carburetor has been overhauled, gently

turn the idle and main fuel mixture screws in by

hand until they seat (Figure 6-14).

Turn the idle mixture screw out 1 turn and the

main fuel mixture screw out 1-3/8 turns so that

the engine will start and run.

Iii

CAUTION! Forcing a

mixture

adjusting

screw

in

tight

will

score

the needle

and

seat.

Turn

it

lightly

by

hand

only.

2.

Start the genset and let it warm up for ten min-

utes under 1/2 to 3/4 rated load.

3.

Disconnect the load (checkforzeroamps). Pull

the governor rod so that the tang on the throttle

lever bears against the idle speed stop screw.

Adjust the screw to obtain 54-56 Hz.

Idle Mixture

and

Frequency

Adjustments:

1.

Disconnect all loads (check for zero amps).

Then check no-load frequency. If necessary,

turn the governor speed adjusting screw (Fig-

6-17

ure 6-13) to obtain a no-load frequency of

62-63Hz.

2. Turn the idle mixture adjusting screw clockwise

until the engine begins to stumble. Then,

counting the number of turns, turn the screw

counterclockwise until it begins to stumble

again. Set the screw halfway in between. For

closer adjustments, use a CO meter to adjust

to 6-8% CO. See

Troubleshooting if the engine

runs roughly.

3.

Push the adjustment limiter cap on over the

mixture screw head such that it will allow equal

adjustment

in

either direction (gasoline carbu-

retors).

4.

If no-load frequency has changed because of

idle mixture adjustment, repeat Step

1.

5.

Check output voltage. See Section

8.

Genera-

tor

if

output voltage cannot be adjusted to with-

in 1 0 percent of rated voltage (Table

6-1

on

Page 6-16).

IDLE MIXTURE

ADJUSTING SCREW CAP

ALTITUDE

SCALE

IDLE SPEED

STOP SCREW

MAIN FUEL MIXTURE

ADJUSTING SCREW CAP

FIGURE 6-14. CARBURETOR

Loading...

Loading...