For

Gensets

Prior

to

Spec F: Adjust lock-off

pressure as follows:

• If the lock-off pressure

is

greater than 0.25

inches (6.4 mm)

we,

remove the locking

screw and back out the adjusting screw

(counterclockwise) until the lock-off pres-

sure falls between 0.15 and 0.25 inch

we

(3.8 and 6.4 mm WC). Set the locking

screw and test lock-off pressure again.

Repeat the procedure if necessary.

• If the lock-off pressure

is

less than 0.15

inch (3.8 mm)

we,

remove the locking

screw and turn

in

the adjusting screw

(clockwise) until the lock-off pressure falls

between 0.15 and 0.25 inch

we

(3.8 and

6.4 mm WC). Set the locking screw and

test lock-off pressure again. Repeat the

procedure if necessary.

• Replace the demand regulator if it contin-

ues to leak after lock-off pressure adjust-

ments have been attempted.

4.

If the genset is mounted

in

a compartment,

make sure the vent/pressure-balance hose

is

routed properly to the outside.

5.

Reconnect the hose to the carburetor, discon-

nect any jumpers which may have been used

to energize the fuel solenoid and thread

in

and

tighten the pressure test port plug.

6.

For gensets prior to Spec

F,

adjust fuel mixture

as instructed under GOVERNOR AND CAR-

BURETOR ADJUSTMENTS

in

this section.

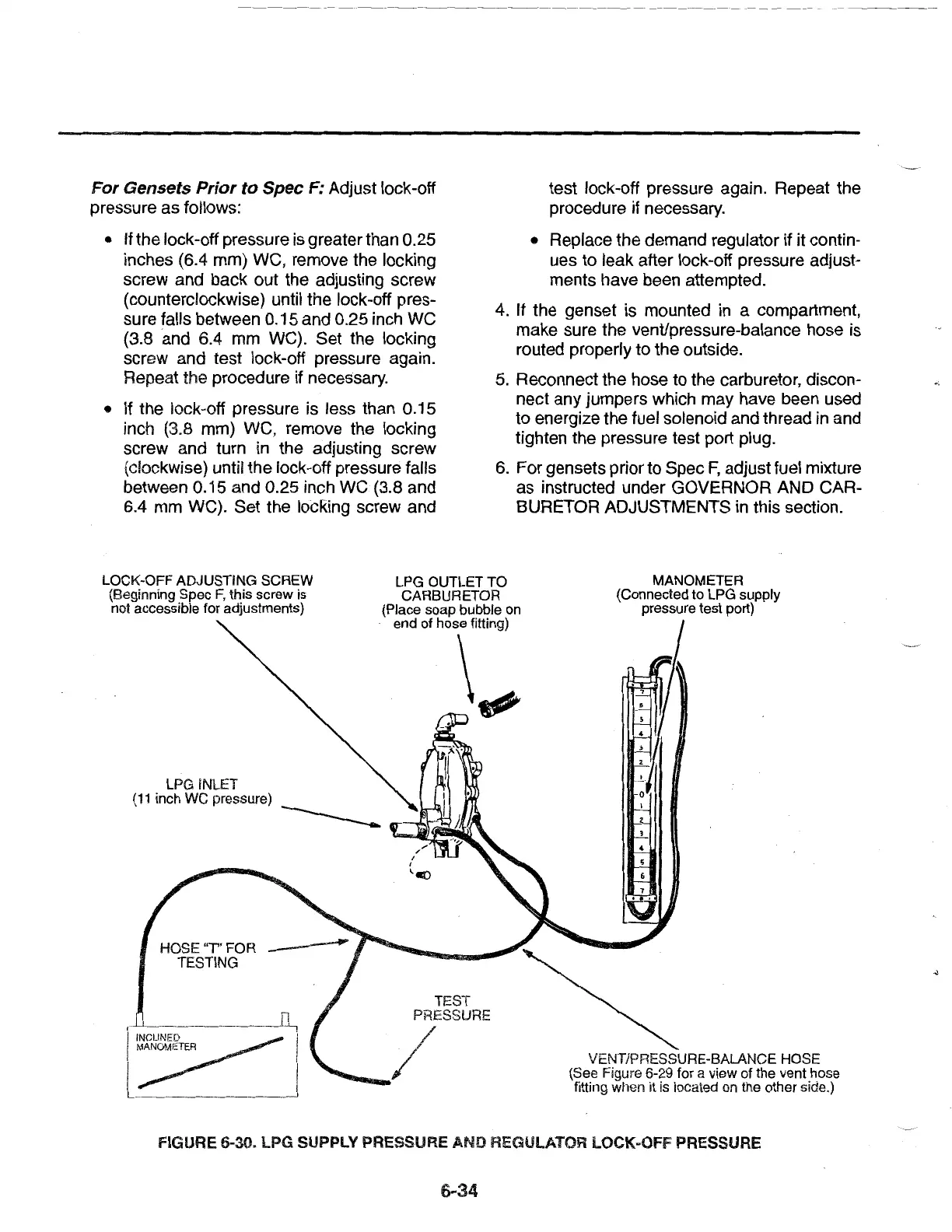

LOCK-OFF ADJUSTING SCREW

(Beginning Spec

F,

this screw is

not accessible for adjustments)

LPG OUTLET TO

CARBURETOR

(Place soap bubble on

end of hose fitting)

MANOMETER

(Connected to LPG supply

pressure test port)

\t?

LPG iNLET

(11

inch

we

pressure)

------

----t:.\-..;';j

HOSE

'T'

FOR

TESTING

~

TEST

PRESSURE

/

/'

- /

VENT/PRESSURE-BALANCE HOSE

(See Figure 6-29 for a view of the vent hose

fitting when it

is

located

on

the other side.)

FIGURE 6-30. LPG

SUPPlY

PRESSURE AND REGULATOR LOCK-OFF PRESSURE

6-34

..)

Loading...

Loading...