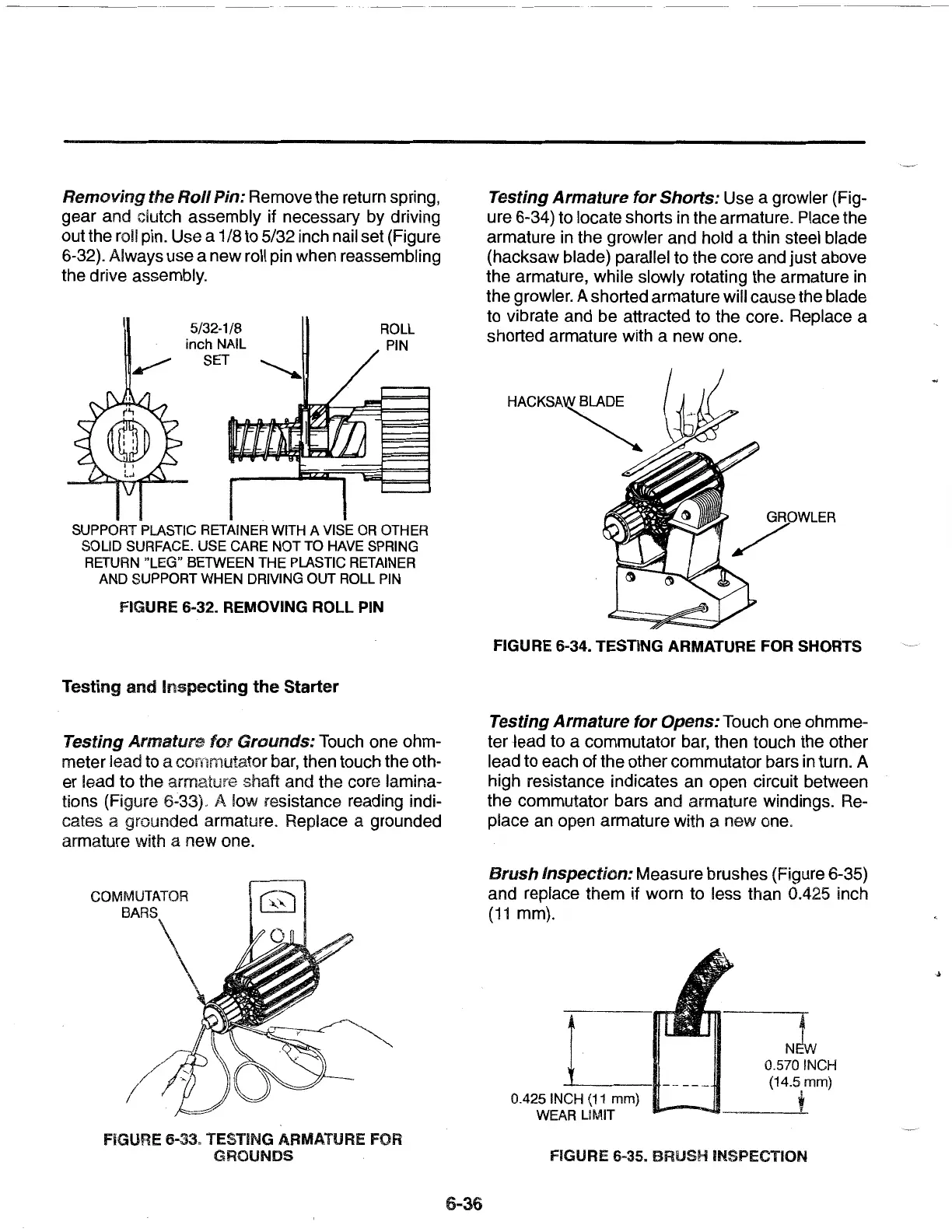

Removing the

Roll

Pin: Remove the return spring,

gear and clutch assembly if necessary by driving

out the roll pin. Use a 1/8 to 5/32 inch nail set (Figure

6-32). Always use a

new

roll pin when reassembling

the drive assembly.

5/32-1/8

inch

NAIL

SET

ROLL

PIN

SUPPORT PLASTIC RETAINER WITH A VISE OR OTHER

SOLID SURFACE. USE CARE NOT TO HAVE SPRING

RETURN "LEG" BETWEEN THE PLASTIC RETAINER

AND SUPPORT WHEN DRIVING OUT ROLL PIN

FIGURE 6-32. REMOVING

ROLL

PIN

Testing and Inspecting the Starter

Testing

Armature

for

Grounds: Touch one ohm-

meter

lead to a commutator bar, then touch the oth-

er lead

to

the armature shaft and the core lamina-

tions (Figure 6-33).

A

low

resistance reading indi-

cates a grounded armature. Replace a grounded

armature with a

new

one.

COMMUTATOR

BARS

FIGURE 6-33. TESTING ARMATURE FOR

GROUNDS

6-36

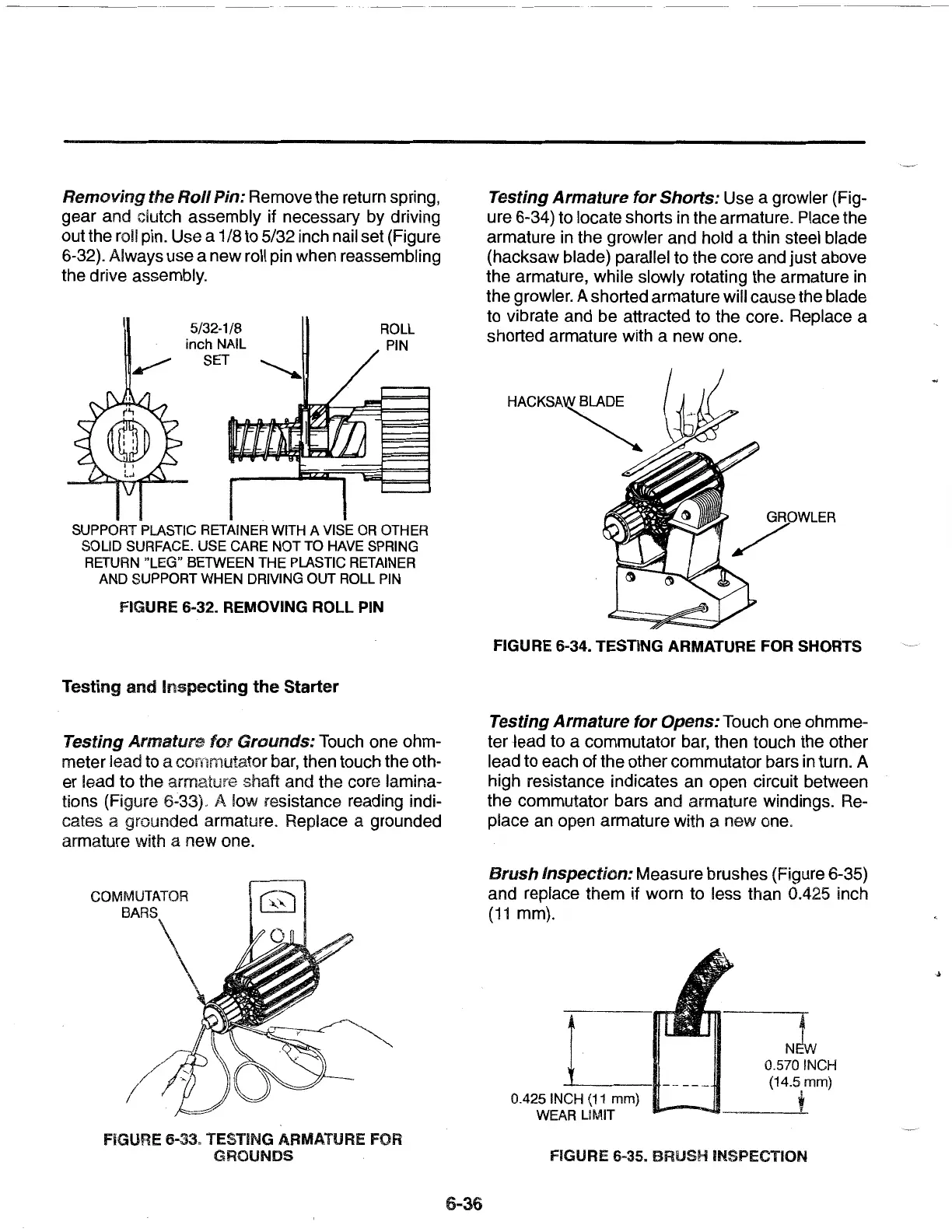

Testing Armature

for

Shorts: Use a growler (Fig-

ure 6-34) to locate shorts in the armature. Place the

armature

in

the growler and hold a thin steel blade

(hacksaw blade) parallel to the core and just above

the armature, while slowly rotating the armature in

the growler.

A shorted armature will cause the blade

to

vibrate and be attracted

to

the

core. Replace a

shorted armature with a

new

one.

HACKSA~

FIGURE 6-34. TESTING ARMATURE FOR SHORTS

Testing Armature

for

Opens: Touch one ohmme-

ter lead to a commutator bar, then touch the other

lead to each

of

the other commutator bars in turn. A

high resistance indicates an open circuit between

the commutator bars and armature windings. Re-

place an open armature with a

new

one.

Brush

Inspection: Measure brushes (Figure 6-35)

and replace them

if

worn to less than 0.425 inch

(11

mm).

0.425 INCH

(11

mm)

WEAR LIMIT

N

0.570 INCH

(14.5 mm)

+

FIGURE 6-35. BRUSH INSPECTION

Loading...

Loading...