5 The solenoid contacts can be checked by

connecting a voltmeter or test lamp between

the battery positive feed connection on the

starter side of the solenoid, and earth. When

the ignition switch is turned to the `start’

position, there should be a reading or lighted

bulb, as applicable. If there is no reading or

lighted bulb, the solenoid is faulty and should

be renewed.

6 If the circuit and solenoid are proved

sound, the fault must lie in the starter motor.

In this event, it may be possible to have the

starter motor overhauled by a specialist, but

check on the cost of spares before

proceeding, as it may prove more economical

to obtain a new or exchange motor.

Removal

1 Disconnect the battery earth lead.

1.2 litre models

2 Disconnect the battery positive leads;

separate the starter motor lead from the other.

Also disconnect the positive lead from the

alternator.

3 Separate the gearshift linkage to improve

access. Unbolt and remove the starter motor

from above, disconnecting the solenoid

command lead.

4 If a new starter motor is being fitted,

transfer the electrical lead to it.

1.4, 1.6, 1.8 and 2.0 litre 8-valve

models

5 Raise and support the front of the vehicle

(see “Jacking and Vehicle Support”).

6 Note the electrical connections to the

starter solenoid, then disconnect them.

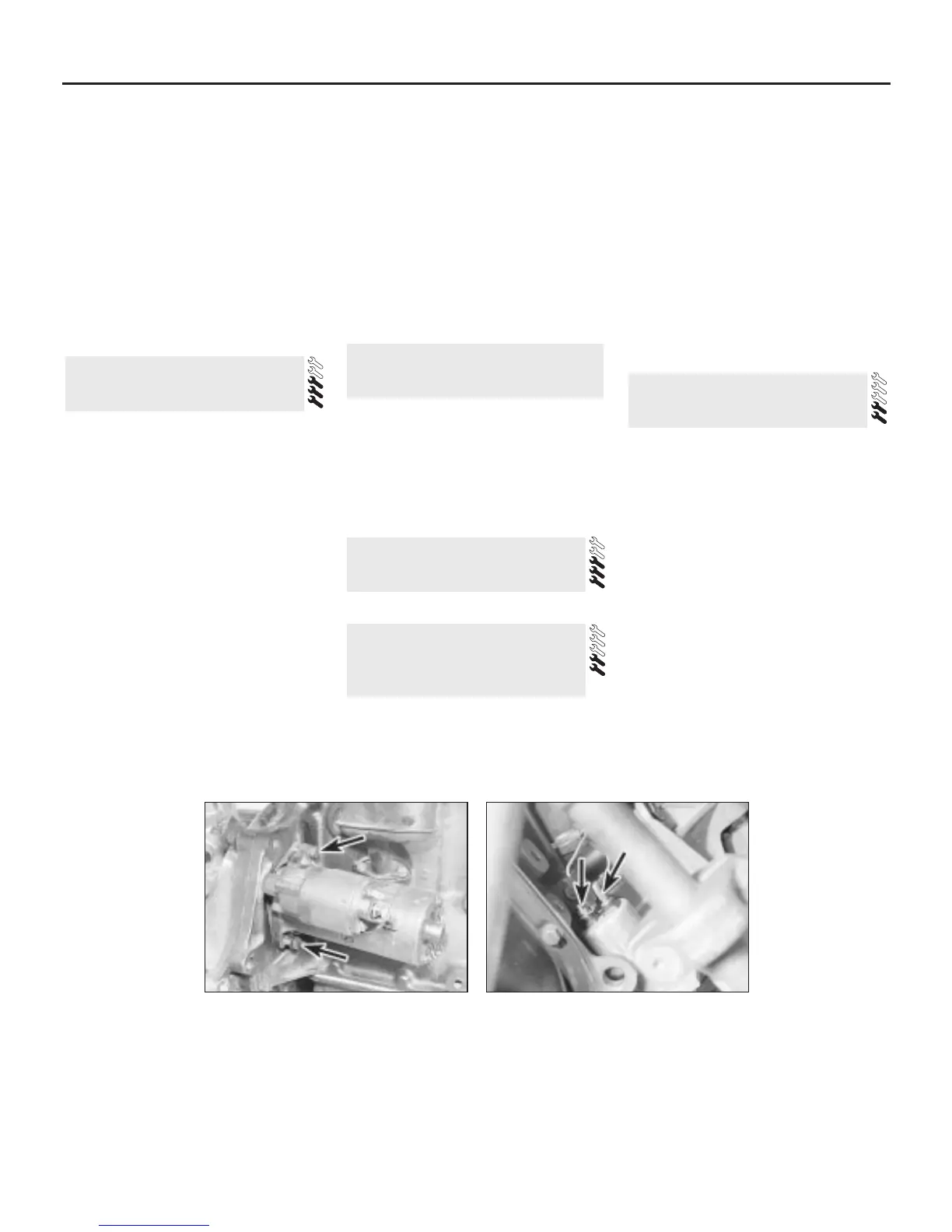

7 Unbolt the starter motor and remove it from

below (see illustration).

2.0 litre 16-valve models

8 Remove the starter motor-to-transmission

bolts which are accessible from above.

9 Raise and support the front of the vehicle

(see “Jacking and Vehicle Support”). Remove

the inlet manifold bracing strap.

10 Disconnect the main feed and command

leads from the starter motor.

11 Remove the remaining starter motor

mounting bolts, not forgetting the bracket at

the brushgear end of the motor. Remove the

motor from below.

Refitting

12 Refitting is the reverse of the removal

procedure.

If the starter motor is thought to be suspect,

it should be removed from the vehicle and

taken to an auto-electrician for testing. Most

auto-electricians will be able to supply and fit

brushes at a reasonable cost. However, check

on the cost of repairs before proceeding as it

may prove more economical to obtain a new

or exchange motor.

Refer to Chapter 10.

Removal

1 The switch/gauge sender is screwed into

the cylinder block or oil filter carrier

(depending on model).

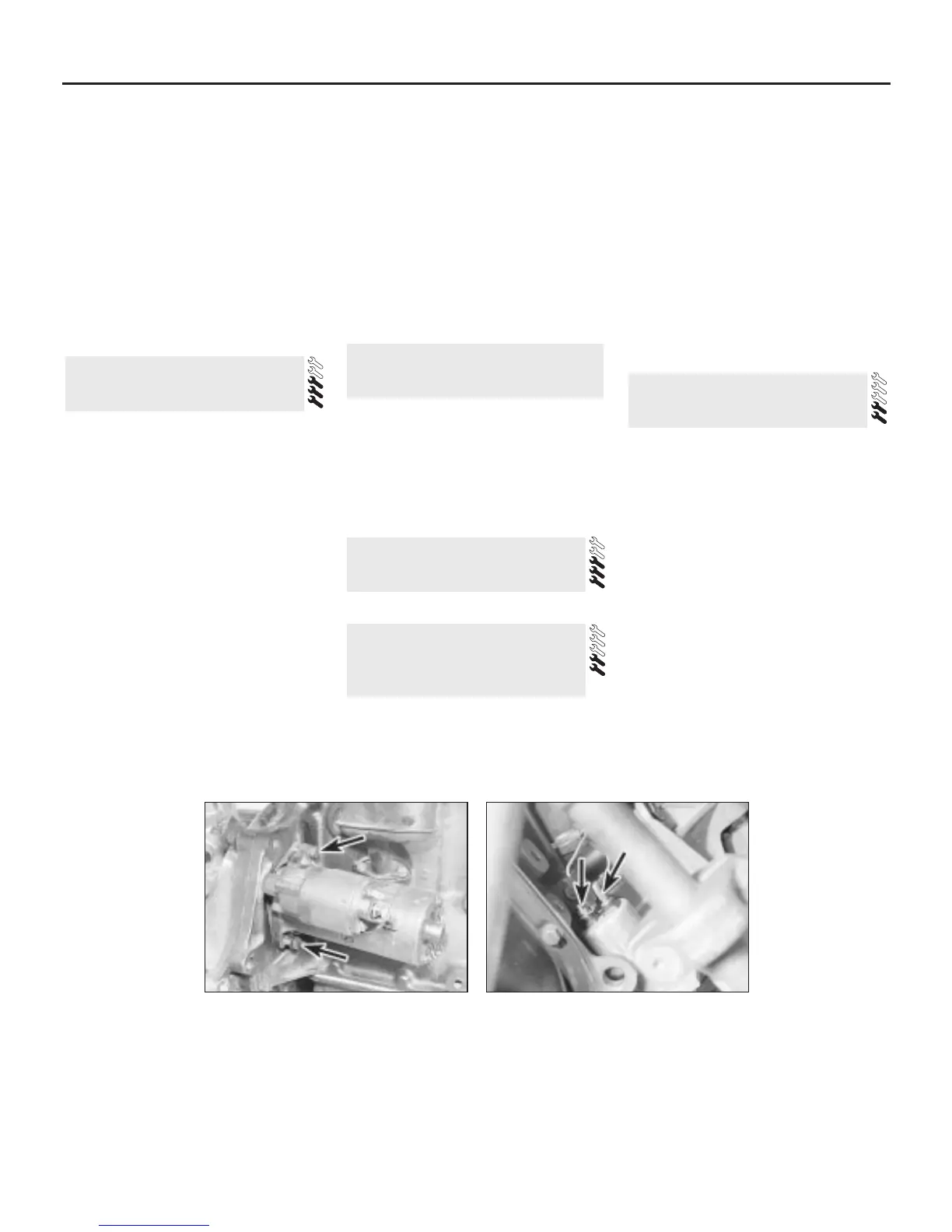

2 Disconnect the battery negative lead and

disconnect the wiring from the switch/sender

(see illustration).

3 Unscrew the switch/sender and recover the

sealing washer. Be prepared for oil spillage,

and if the switch is to be left removed from the

engine for any length of time, plug the hole.

Refitting

4 Examine the sealing washer for signs of

damage or deterioration and if necessary

renew.

5 Refit the switch/sender, complete with

washer, and tighten it securely. Reconnect the

wiring.

6 Check and, if necessary, top-up the engine

oil as described in Chapter 1.

Removal

1 Raise and support the front of the vehicle

(see “Jacking and Vehicle Support”).

2 Disconnect the battery earth (negative)

lead.

3 Drain the engine oil, saving it if it is fit for

re-use.

4 Follow the sensor wiring back to its

connection with the main wiring harness and

disconnect it. (Early type sensors have a

wiring plug secured with two screws, which

can be disconnected at the sensor.)

5 Remove the four screws which secure the

sensor to the sump. Remove the sensor and

recover the seal.

Refitting

6 Refitting is the reverse of the removal

procedure. Use a new seal. Refill the engine

with oil on completion.

14 Oil level sensor (16-valve

models) - removal and refitting

13 Oil pressure warning light

switch/gauge sender -

removal and refitting

12 Ignition switch - removal and

refitting

11 Starter motor - testing and

overhaul

10 Starter motor - removal and

refitting

5A•4 Starting and charging systems

10.7 Starter motor mounting bolts

(arrowed) - engine removed for clarity

13.2 Oil pressure sender wires (arrowed)

Loading...

Loading...