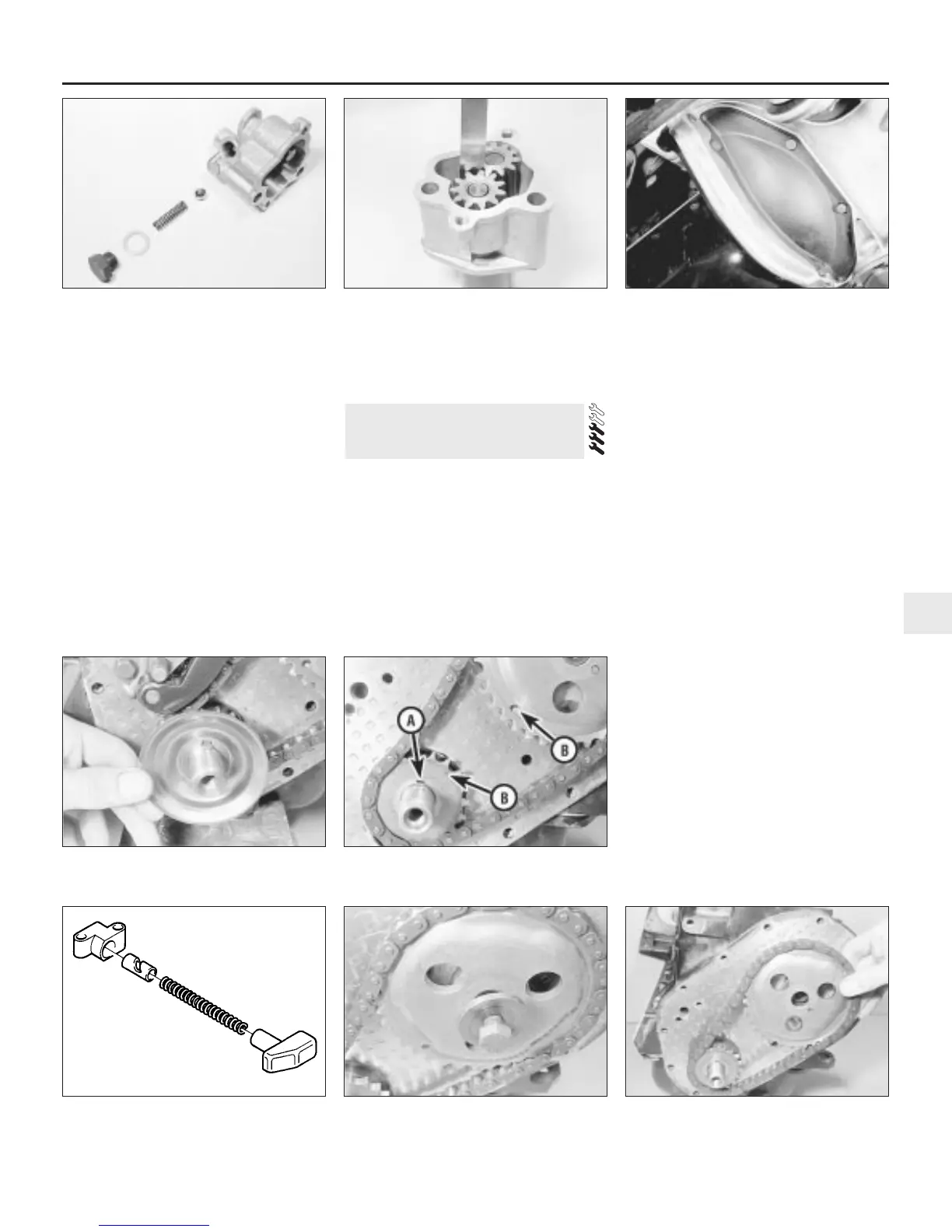

4 Undo the large nut on the side of the

housing and remove the sealing washer and

oil pressure relief spring and ball valve (see

illustration).

5 Clean all the parts in paraffin and dry with a

lint-free cloth.

6 Inspect the pump gears, housing, cover

and relief valve ball for scoring, scuff marks or

other signs of wear and renew the pump if

these signs are evident.

7 If the pump condition is satisfactory, check

the pump clearances as follows.

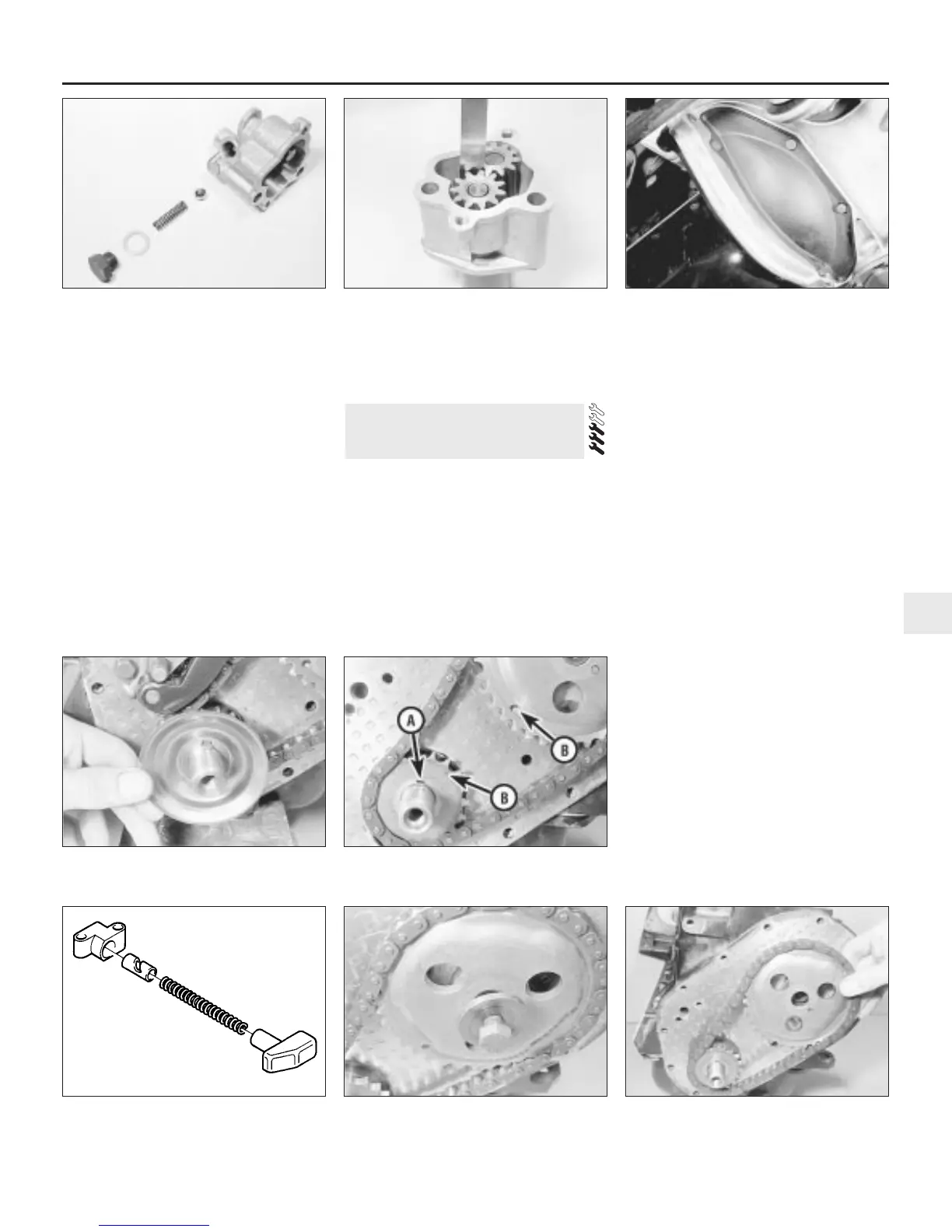

8 Using a feeler blade, check the backlash

between the gear teeth. Place a straight-edge

across the top edge of the gears and check

their projection. If any of the clearances

exceeds the tolerances given in the

Specifications, renew the pump (see

illustration).

9 If the clearances are satisfactory, refit the

relief valve assembly and assemble the pump

gears. Fill the pump with oil and refit the cover

using a new gasket. Tighten the cover

securing bolts and refit the pump.

Removal

1 For greater access remove the front

right-hand wheel trim and slacken the wheel

bolts. Jack up the front of the car, support it

securely on axle stands (see “Jacking and

Vehicle Support”) and remove the roadwheel.

2 Undo the four retaining bolts and remove

the clutch access plate at the base of the

bellhousing (see illustration).

3 Slacken the alternator mounting and

adjustment arm bolts, move the alternators

towards the engine and slip the drivebelt off

the pulleys.

4 Lock the flywheel by wedging a screwdriver

between the ring gear teeth and the side of

the bellhousing.

5 Using a socket or spanner undo the

crankshaft pulley retaining bolt and withdraw

the pulley.

6 Undo the bolts securing the timing cover to

the front of the engine and lift off the cover.

7 Withdraw the oil slinger from the

crankshaft, noting which way round it is fitted

(see illustration).

8 Temporarily refit the pulley and turn the

crankshaft until the crankshaft sprocket

keyway is uppermost and the timing marks on

the two sprockets are in alignment (see

illustration). Remove the pulley.

9 Undo the two retaining bolts and remove

the timing chain tensioner. One of two types

of tensioner may be fitted: simple

spring-operated, or oil pressure assisted. With

the oil pressure assisted type, restrain the

thrust pad to prevent premature ejection of

the tensioner components (see illustration).

10 Undo the camshaft sprocket retaining bolt

and remove the bolt and washer (see

illustration). Place a screwdriver through one

of the sprocket holes and in contact with the

camshaft retaining plate behind the sprocket

to stop it turning as the bolt is undone.

11 Withdraw the camshaft sprocket and

crankshaft sprocket from their respective

locations, using a screwdriver as a lever if

necessary, then remove the sprockets

complete with chain (see illustration).

12 Thoroughly clean all the components in

14 Timing gear components -

removal and refitting

OHV engine 2A•9

2A

14.2 Clutch access plate

14.11 Removing the sprockets and timing

chain

14.10 Camshaft sprocket retaining bolt

and washer

14.9 Timing chain tensioner - oil pressure

assisted type

14.7 Crankshaft oil slinger 14.8 Crankshaft sprocket keyway (A) and

sprocket timing marks (B)

13.8 Check the pump gear teeth backlash13.4 Oil pump and pressure relief valve

components

Loading...

Loading...