along the line of the crack in the plastic using

a rotary burr in a power drill. The damaged

part is then welded back together by using a

hot air gun to heat up and fuse a plastic filler

rod into the groove. Any excess plastic is then

removed and the area rubbed down to a

smooth finish. It is important that a filler rod of

the correct plastic is used, as body

components can be made of a variety of

different types (eg. polycarbonate, ABS,

polypropylene).

25 Damage of a less serious nature

(abrasions, minor cracks etc) can be repaired

by the DIY owner using a two-part epoxy filler

repair material, or a no-mix filler which can be

used directly from the tube. Once mixed in

equal proportions (or applied directly from the

tube in the case of a no-mix filler), this is used

in similar fashion to the bodywork filler used

on metal panels. The filler is usually cured in

twenty to thirty minutes, ready for sanding

and painting.

26 If the owner is renewing a complete

component himself, or if he has repaired it

with epoxy filler, he will be left with the

problem of finding a suitable paint for finishing

which is compatible with the type of plastic

used. At one time the use of a universal paint

was not possible owing to the complex range

of plastics encountered in body component

applications. Standard paints, generally

speaking, will not bond to plastic or rubber

satisfactorily, but a professional spraymatch

paints to match any plastic or rubber finish

can be obtained from dealers. However, it is

now possible to obtain a plastic body parts

finishing kit which consists of a pre-primer

treatment, a primer and coloured top coat.

Full instructions are normally supplied with a

kit, but basically the method of use is to first

apply the pre-primer to the component

concerned and allow it to dry for up to 30

minutes. Then the primer is applied and left to

dry for about an hour before finally applying

the special coloured top coat. The result is a

correctly coloured component where the paint

will flex with the plastic or rubber, a property

that standard paint does not normally posses.

Where serious damage has occurred, or

large areas need renewal due to neglect, it

means that complete new panels will need

welding in, and this is best left to

professionals. If the damage is due to impact,

it will also be necessary to check completely

the alignment of the bodyshell, and this can

only be carried out accurately by a

Vauxhall/Opel dealer using special jigs. If the

body is left misaligned, it is primarily

dangerous as the car will not handle properly,

and secondly, uneven stresses will be

imposed on the steering, suspension and

possibly transmission, causing abnormal

wear, or complete failure, particularly to such

items as the tyres.

Removal

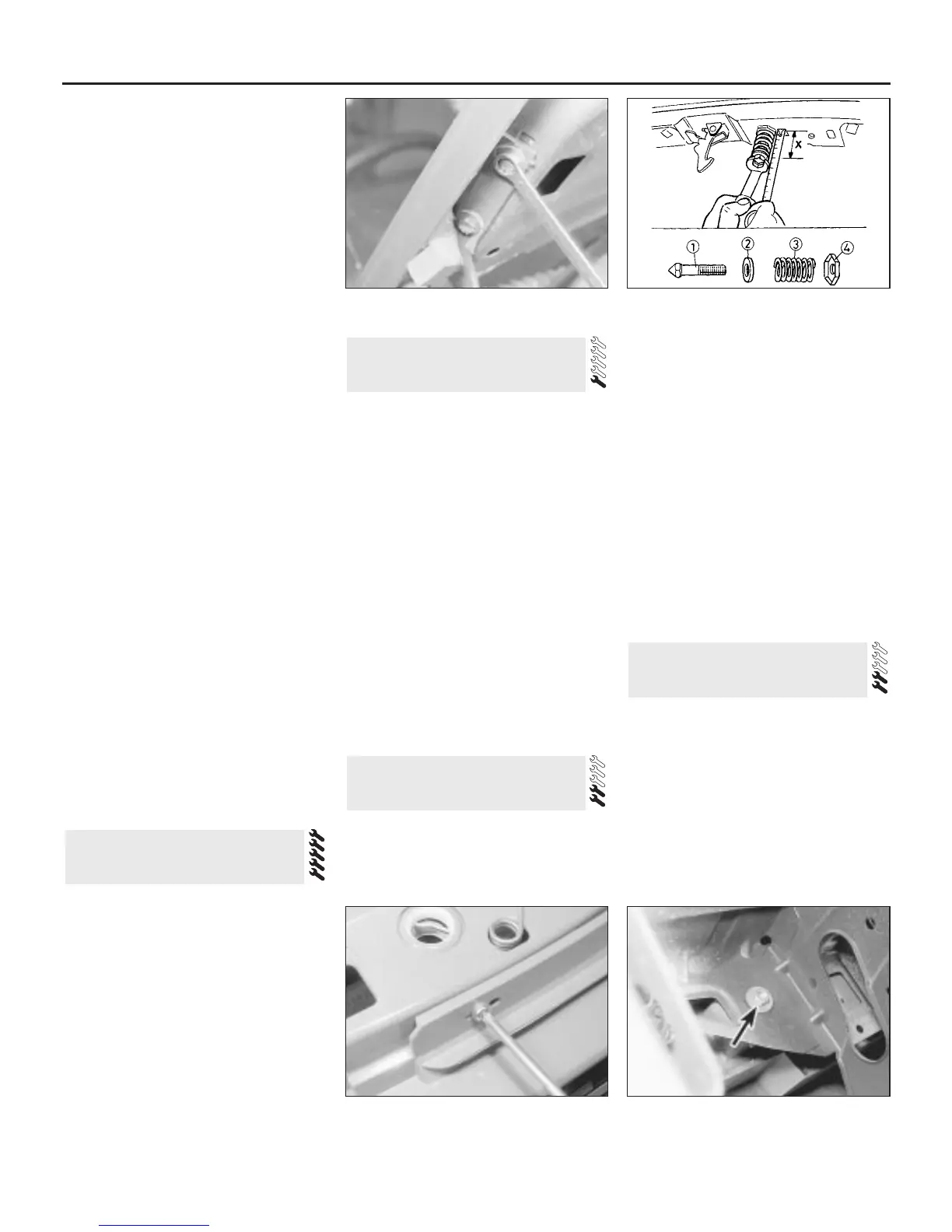

1 Open and prop the bonnet.

2 When an under-bonnet light is fitted,

disconnect its electrical lead.

3 Mark around the hinge bolts with a soft lead

pencil as a guide for refitting. Have an

assistant support the bonnet, then remove the

hinge bolts from each side (see illustration).

4 Lift away the bonnet. If it is to be re-used,

rest it carefully on rags or cardboard. If a new

bonnet is to be fitted, transfer serviceable

items (rubber buffers, lock striker etc) to it.

Refitting

5 Refit in the reverse order to removal, using

the hinge bolt alignment marks for guidance

when applicable.

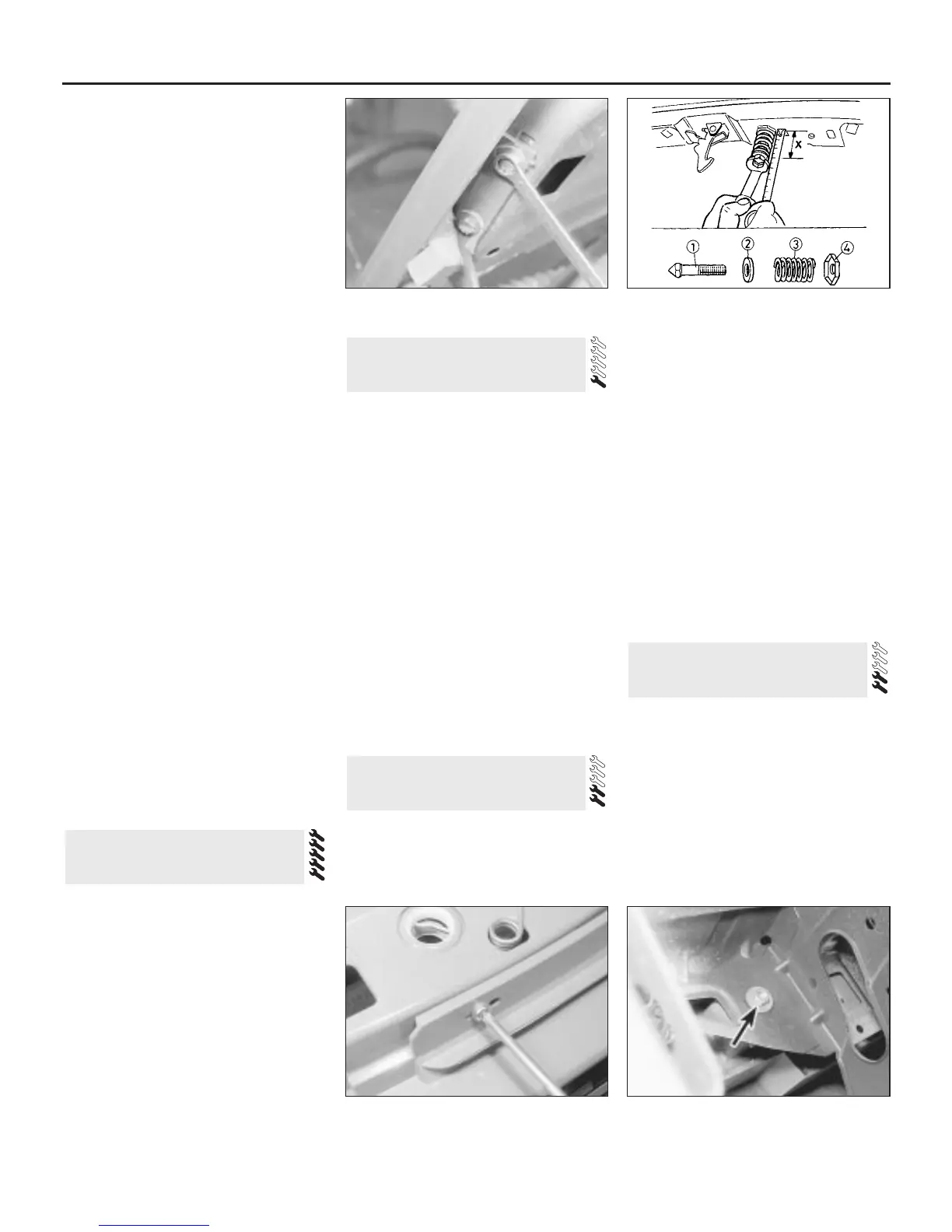

6 If the lock striker was disturbed, adjust it to

the dimension shown before tightening its

locknut (see illustration).

7 Adjust the hinge bolts and front buffers until

a good fit is obtained with the bonnet closed.

Removal

1 Open up the bonnet and unbolt the cable

clip from the rear of the bonnet lock platform.

2 Prise the cable and fitting out of the release

slide, using a screwdriver against the spring

tension.

3 Inside the car, free the cable from the

release lever and bracket.

4 Release the grommet from the bulkhead

and withdraw the cable from under the

bonnet.

Refitting

5 Fit the new cable in the reverse order to

removal. Adjust the position of the cable

under the front panel clip so that, with the

release lever at rest, the inner cable is just

slack. Check that the release slide moves

when an assistant operates the release lever,

then close the bonnet and check for correct

operation.

Removal

1 The front trim panel incorporates the

radiator grille and the front bumper.

2 Remove the three screws which secure the

panel to the bonnet lock platform (see

illustration).

3 From under the vehicle remove the two

nuts which secure the lower part of the panel

(see illustration).

4 Pull the panel forwards so that it slides off

the side mountings. If front foglights are fitted,

8 Front trim panel - removal and

refitting

7 Bonnet release cable - removal

and refitting

6 Bonnet - removal and refitting

5 Major body damage - repair

11•4 Bodywork and fittings

6.6 Bonnet lock striker adjustment

1 Striker

2 Washer

3 Coil spring

4 Locknut

X = 40 to 45 mm

8.3 Front trim panel securing nut (arrowed)8.2 Undoing a front trim panel screw

6.3 Removing a bonnet hinge bolt

Loading...

Loading...