7

OPTION 2: MOUNT THE WELDER TO THE SIDE OF THE CNC TABLE

STEP 1: CONNECT THE WELDER TO THE SIDE BRACKET ON THE CNC TABLE

Step 3: Connect the power cable and AC power

1. Plug the power

cable into the

back of the

welder.

2. Plug the other

end into the

power supply

box.

3. Now plug the

AC power cord

into the other

side of the power

supply box .

4. Last, plug the

end of the AC power cord into any standard 110-220VAC outlet.

Step 4: Argon Setup

Use protective shielding gas, such as 99.996% pure Argon (Argon 4.6) or higher.

1. Ensure that your shielding gas tank is securely fastened to a stationary point near the

welding area.

1. 2.

3.

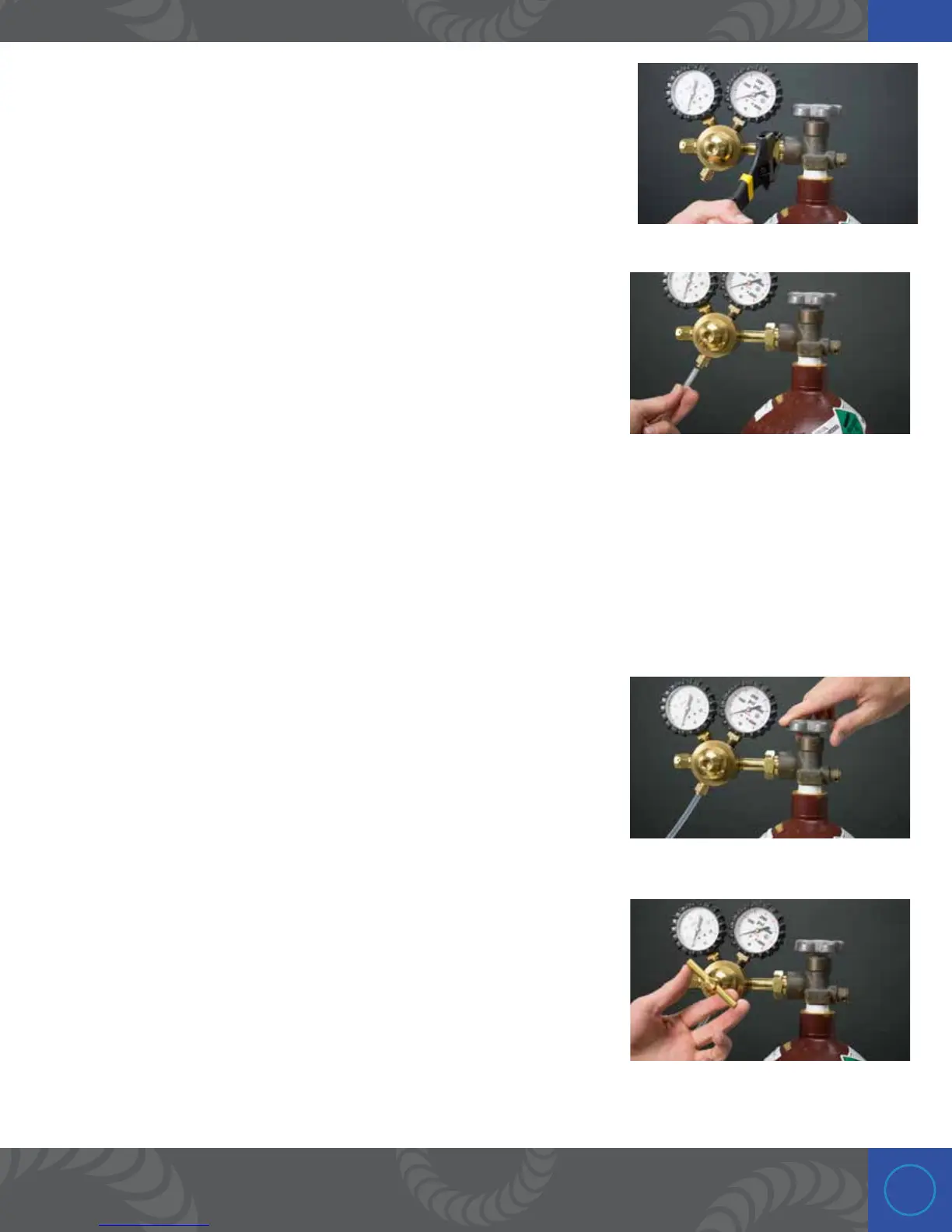

2. Turn the regulator dial COUNTER CLOCKWISE (closed) until it is fully

backed out to prevent over-pressurization of the line.

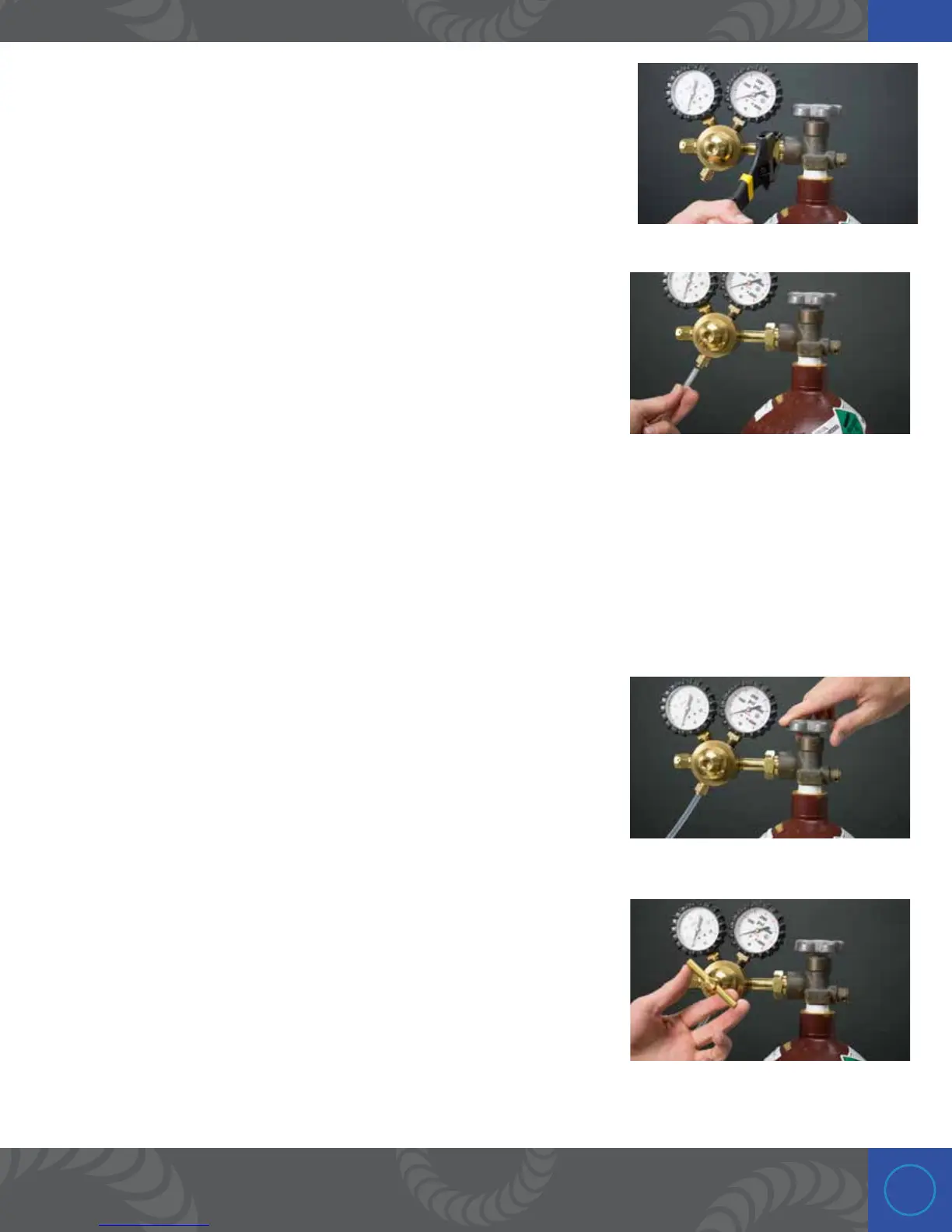

3. Screw the gas regulator onto the shielding gas tank.

4. Connect one end of the gas tubing into the gas regulator. It will stop

when it is fully connected. Tug gently on the tube to verify a tight fit.

5. Insert the other end of the gas tubing into the gas port on the top of

the weld head. It will stop when it is fully connected. Tug gently on the

tube to verify a tight fit.

6. Open the gas tank slowly. e dial on the right should pressurize and

the dial on the right should remain at zero (when the regulator dial is

fully backed out – see step 2).

7. Slowly turn the regulator dial CLOCKWISE until the gas pressure

reads between 7-10 psi. (is will adjust the dial on the left side of the

regulator.)

Loading...

Loading...