11OrionWelders.com

the tank could become rocket-like, expelling the high pressure shielding gas as

propellant.

• Always turn off the shielding gas at the main valve when finished. is will help

your shielding gas supply last longer in case there is a small leak in the tubing.

is is also a good safety practice. If the tube becomes dislodged shielding gas

could fill the room and displace oxygen, which can lead to suffocation. Argon is

heavier than air and will fill the room from the bottom upward. If you experience

a large shielding gas leak, open all of the doors and windows in the room.

SHIELDING GAS TANK AND REGULATOR SETUP

• Ensure that your shielding gas tank is securely fastened to a stationary point near the welding area.

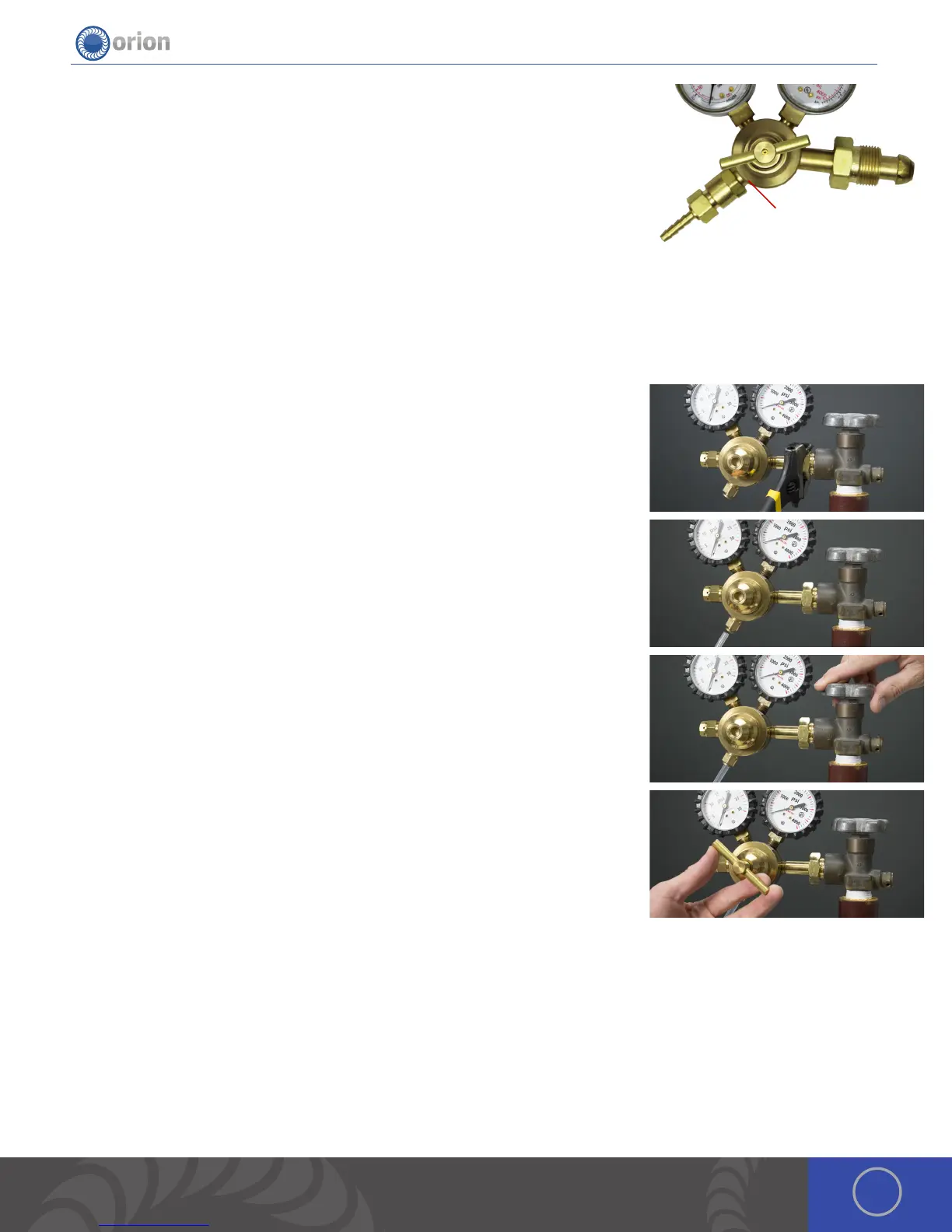

• Turn the regulator dial COUNTER CLOCKWISE (closed) until it is fully backed out. meaning the dial become loose, to

prevent over-pressurization of the line.

• Screw the gas regulator onto the shielding gas tank.

• Connect one end of the gas tubing to the gas regulator.

• Insert the other end of the gas tubing into the gas port on the back of the power

supply. It will stop when it is fully connected. Tug gently on the tube to verify a

tight fit.

• Open the gas tank slowly. e dial on the right should pressurize and the dial on

the left should remain at zero (when the regulator dial is fully backed out or the

dial becomes loose).

• Slowly turn the regulator dial CLOCKWISE until the gas pressure reads between

7-10 psi. (is will adjust the dial on the left side of the regulator.)

Regulator Dial

Loading...

Loading...