OSAKA – F 1 – User’s Manual – v1 – PAG. 10

6.2 – CLEANING

It is recommended to clean the controller with a wet cloth alone. Do

not use soap nor any other neutral detergent.

6.3 – WARRANTY AND REPAIRING

The controller has a warranty that takes form either in reparation or

in replacement, if the error is due to a manufacturing defect in

materials which are up to 12 months old from the purchasing date.

OSAKA SOLUTIONS will automatically make void this warranty and

will not be held accountable for possible damage that may result

from:

- The use, installation or handling which is inappropriate or

different than the one written here, and specially when is

differs from the safety requirements established by the

regulation.

- The usage in applications, machines or electrical panels

that do not provide adequate protection against liquids,

dust, grease and electric shocks in the conditions of

mounting.

- The inexperienced handling, and / or alteration of the

product.

- The installation / use in applications, machines or

electrical panels that do not comply with the valid norm.

If the product has a defect during the warranty time or outside of

aforementioned time, you should contact the after-sales service to

go through the appropriate procedure. Request a repairing

document “RMA” (by email or fax) and fill it. It is necessary to send

the RMA and the controller to the SAT OSAKA with prepaid

shipping.

7.1 – ELECTRICAL FEATURES

Supply: 115 or 230 VAC +/- 10%

AC Frequency: 50/60 Hz

Consumption: 2 VA

Input: 2 inputs for NTC (103AT-2, 10 K Ω @ 25 °C) temperature

probes; 1 digital input by free voltage contact as an alternative

option to the 2 probe inputs.

Output - 16A -

1HP 250V,

1/2HP 125 VAC

Electrical life relay output: 100000 op. in compliance with EN 60730

Supply: Type 1.B in compliance EN 60730-1

Overvoltage category: II

Device’s class: Class II

Isolation: Isolated by piece low voltage (power 115/230 V and relay

outputs); and part low voltage inputs; electrically isolated between

output and supply.

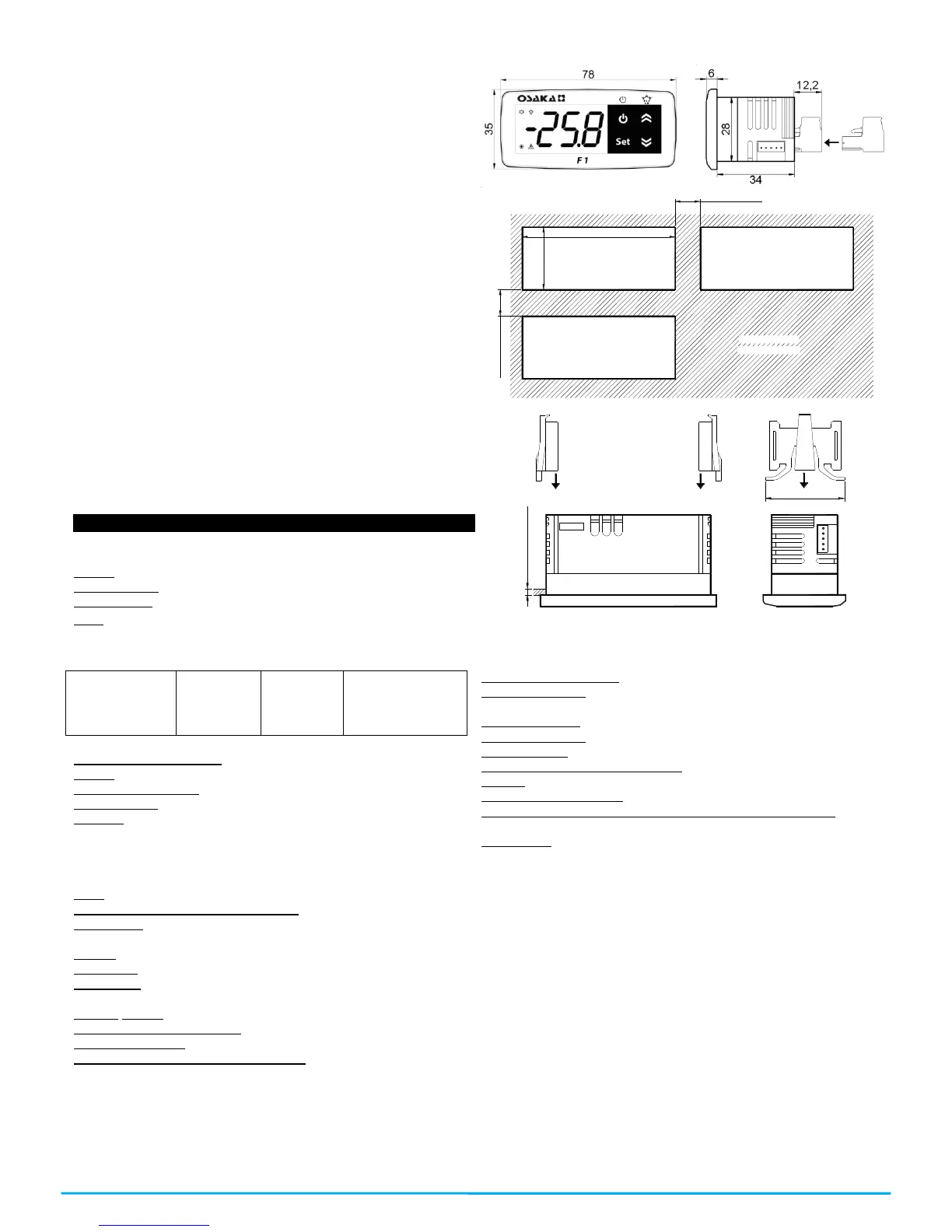

7.2 – MECHANICAL FEATURES

Body: Self-extinguishing UL 94 V0 plastic.

Category of resistance to heat and fire: D

Dimensions: 78 X 35 mm, depth. 34 mm or 42.2 according to the

terminal block.

Weight: 105 g approx.

Installation: on panel, recessed 71x29mm

Connection: Inputs: Cable of 0,14…4,5mm

2

/ AWG 28...16;

Supply and output: 0,2…2,5 mm

2

/ AWG 24...14

Sealing degree: IP65 (NEMA 3S) with sealing gasket

Operating room temperature: 0 T 50 ° C

Operating humidity: <95% RH non-condensing

Storage and transportation temperature: -25 ° C T 60

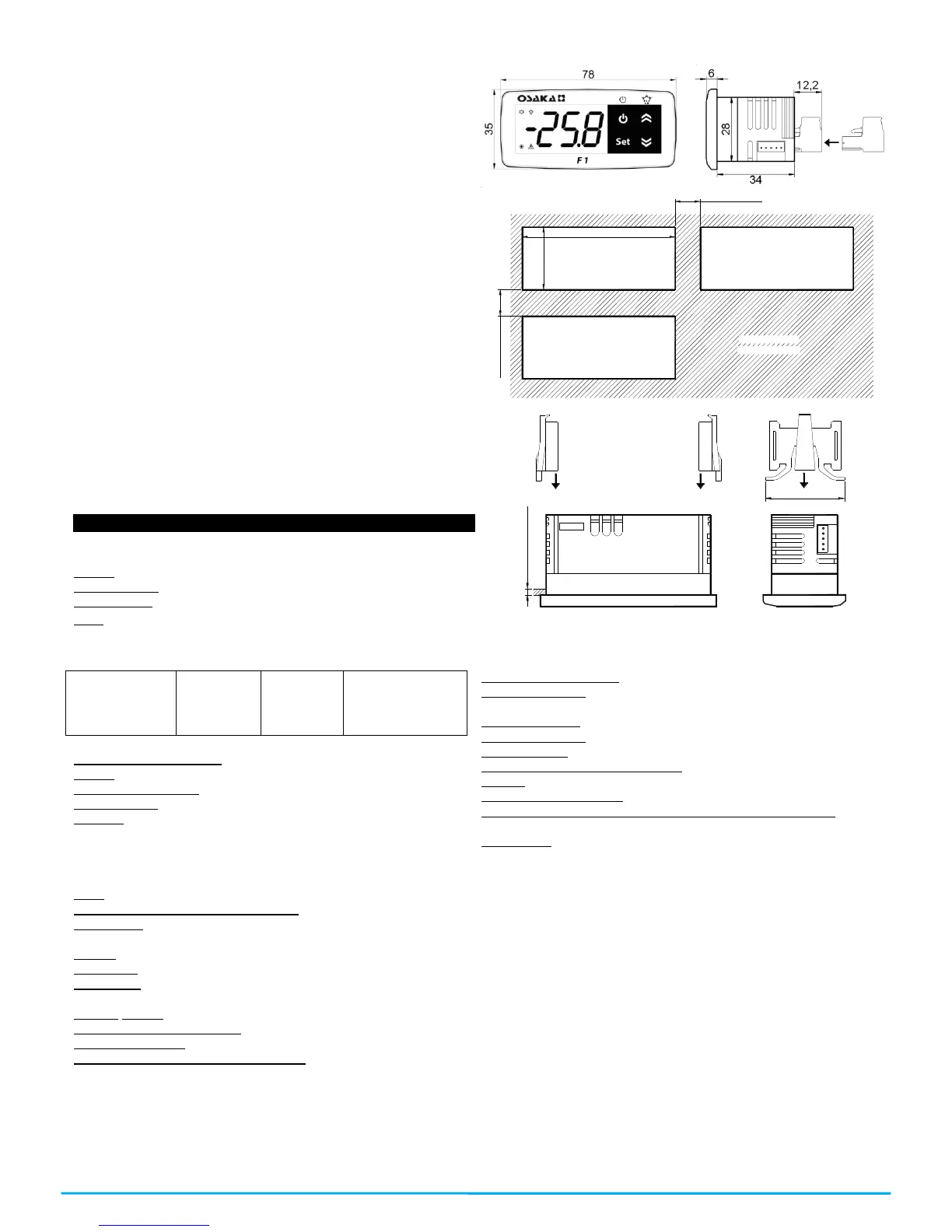

7.3 – MECHANICAL DIMENSIONS, HOLES, AND MOUNTING

R E C O M M EN D E D

P AN EL C U TO U T

29

m in . 1 5 m m

m in . 1 2 m m

71

P A N E L

B RA C K E T S

34

M A X . 2 ,5 m m

7.4 – FUNCTIONAL FEATURES

Temperature regulation: ON/OFF

Defrosting control: By intervals due to the stoppage of the

compressor.

Measuring range: -50…109ºC / -58…228 ºF.

Display resolution: 1º or 0,1º (range -99.9…99.9 ºC)

Total accuracy: +*- (0,5% fs + 1 digit)

Average speed time (without filter): 130 ms.

Display: 3 red digits h 15,5mm.

Software class structure: Class A

Time maintenance of the internal clock without power supply:

Around four hours.

Compliance: 2004/108/CE (EN55022: class B; EN61000-4-2: air

8KV, contact 4KV.; EN61000-4-3: 10V/m; EN61000-4-4: power

supply 2KV relay output, 1KV inputs; EN61000-4-5: common power

supply 2KV, 1 KV\ differential mode; EN61000-4-6: 3V); Directive

2006/95/CE (EN 60730-1, EN 60730-2-9).Regulation 37/2005/CE

(EN13485 air, S, A, 2,- 50°C +90°C if it is used with NTC probe

103AT11).

Loading...

Loading...