PGC, Inc 500-1000 CFM Air Handler May 2006

Appendix A A-3

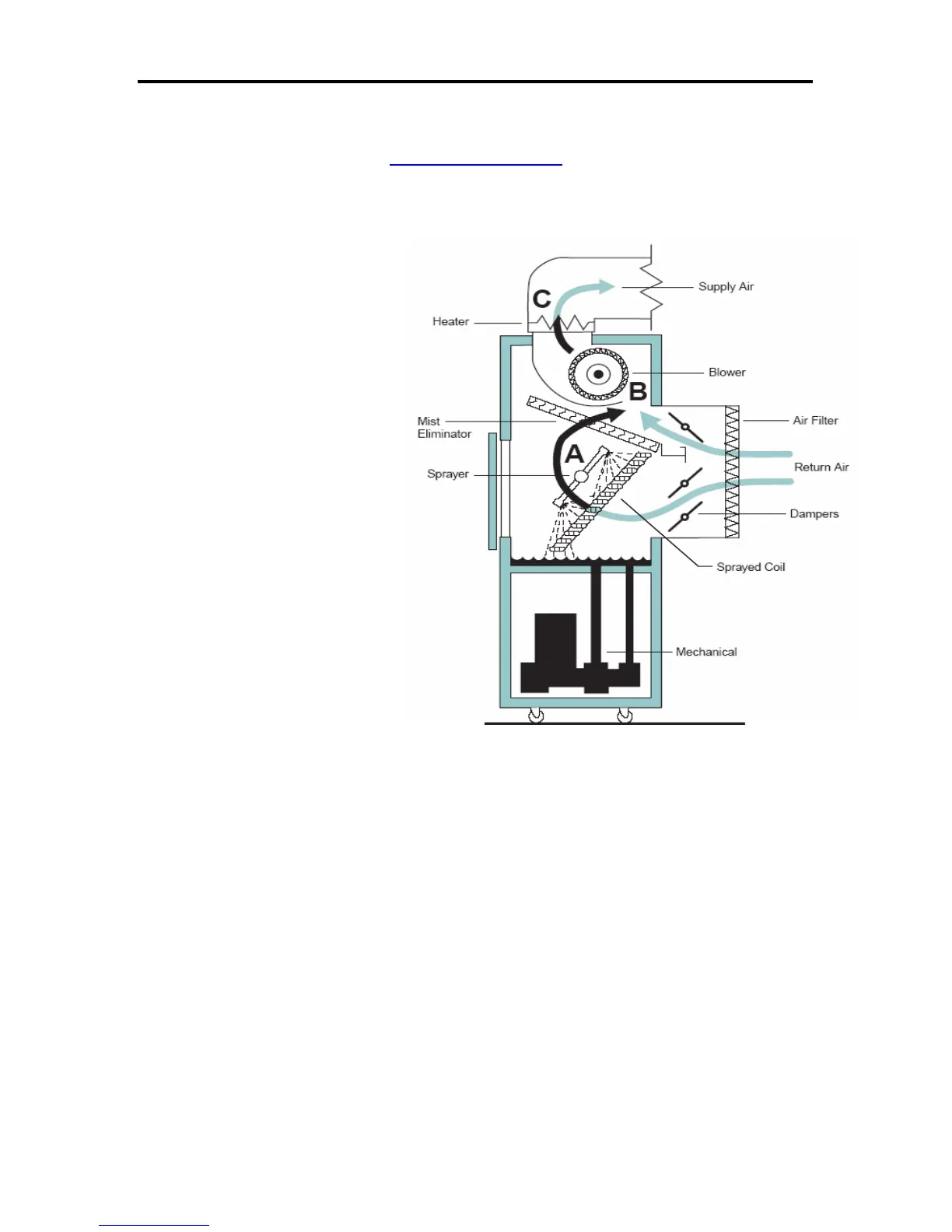

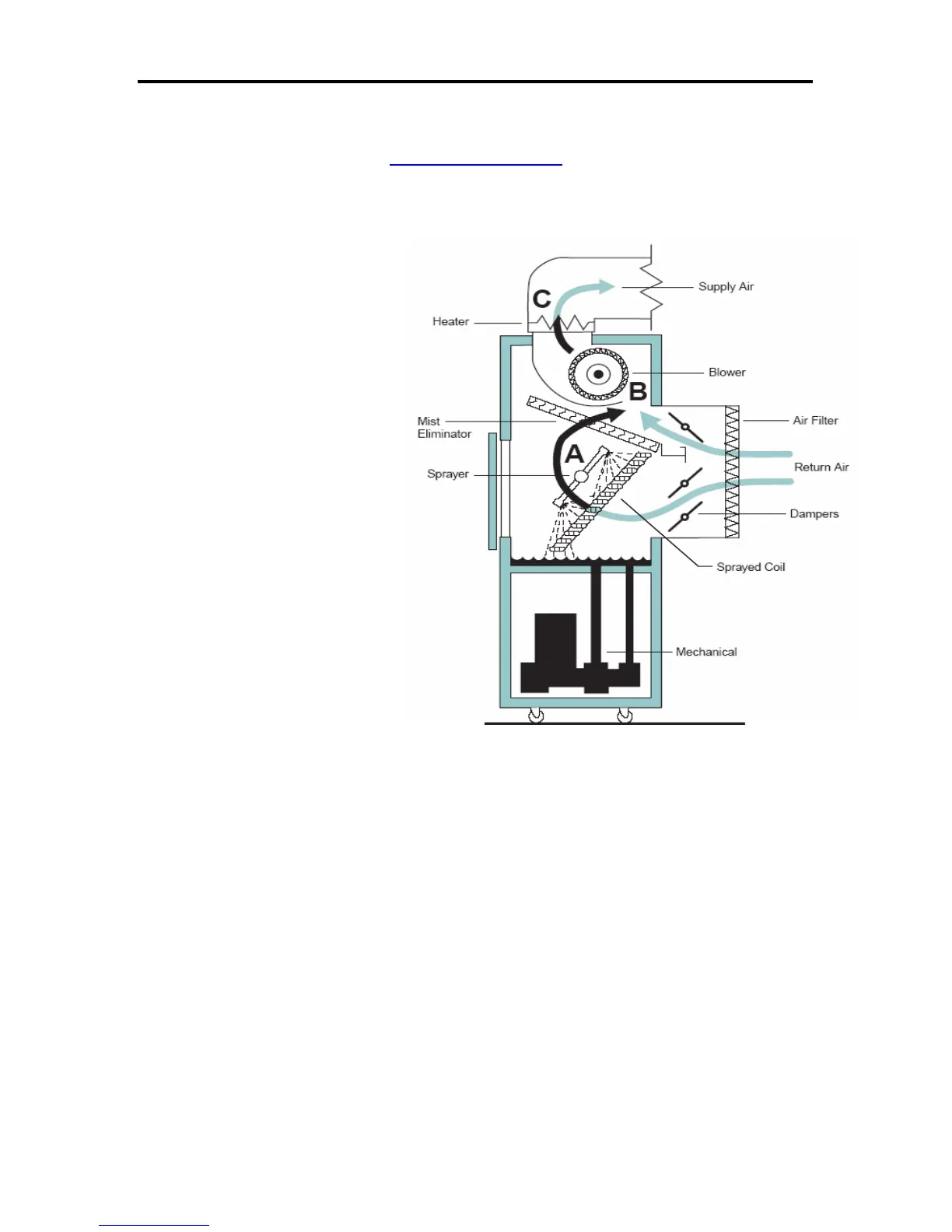

THEORY OF OPERATION

PGC’s method of control is the

same for both reach-in

chambers and conditioning

systems. The environment to be

conditioned is controlled at a

targeted dew point temperature,

and then reheated to the desired

air temperature. This

methodology follows a proven

technique that maintaining a

constant dew point and air

temperature will produce a very

constant relative humidity. The

desired air temperature and

relative humidity or water

temperature are set via the

SmartPad™. If equipped with

an optional recorder, it can be

wired to record the actual air

temperature and relative

humidity or water temperature.

The air is cooled by means of a

water spray which constantly

sprays water across the air

stream, saturating the air. A

submerged refrigeration

evaporator coil operates 1°C-

2ºC (1.8°F-3.6°F) below the

desired dew point and cools the

water that is sprayed across the

air stream. The air is then re-

heated before it is returned to

the test chamber.

NOTE

Dew point is the temperature at which the air can contain no more moisture and

some moisture begins to condense.

A portion of the air can be diverted around the water spray saturator by a bypass damper. If the

air does not pass through the water spray, it will not be cooled; if the air is not cooled, it will not

require as much (if any) air heat to be applied before it is returned to the test chamber. The

amount of air that passes through the saturator, or bypasses the saturator, is determined by the air

temperature control loop.

Mechanical

Sprayed Coil

Supply Air

Blower

Air Filter

Return Air

Dampers

Figure A-1 - Generic Conditioning Unit

Loading...

Loading...