PGC Inc. Horizontal 500-1000 CFM June 2006

Parameter Generation and Control, Inc.

4

Inspection

If the equipment is damaged upon receipt, immediately request the delivering carrier to

perform an inspection and prepare a report. All claims for damage must be made against

the delivering carrier. Report the nature and extent of the damage to PGC, 828-669-8717,

and include instrument serial and catalog numbers to facilitate repair or replacement.

Installation

The 500-1000 CFM Conditioner was designed to be located adjacent to or on top of the

chamber to be conditioned. Allow at least 36 inches on the right side and front of the unit

for service. The location must be convenient to an adequate process water supply, drains

and electrical power. The conditioner must be reasonably level for proper water level

control.

Electrical power and water must be connected to this unit prior to operation. The required

voltage and current are listed on the nameplate located on the unit. The sump drain may

be connected directly to a facility drain, but the condensate drain must be connected to an

open (vented) trapped drain (see Figure 3) to ensure that backpressure on the facilities’

drain does not prevent proper drainage.

Note

The condensate drain has been supplied with a copper trap.

Plumbing

CAUTION

To prevent damage to the water pump and water heater, the unit must not

be operated until water is supplied to the unit and the sump has filled to the

proper level.

Process Water Supply Specifications

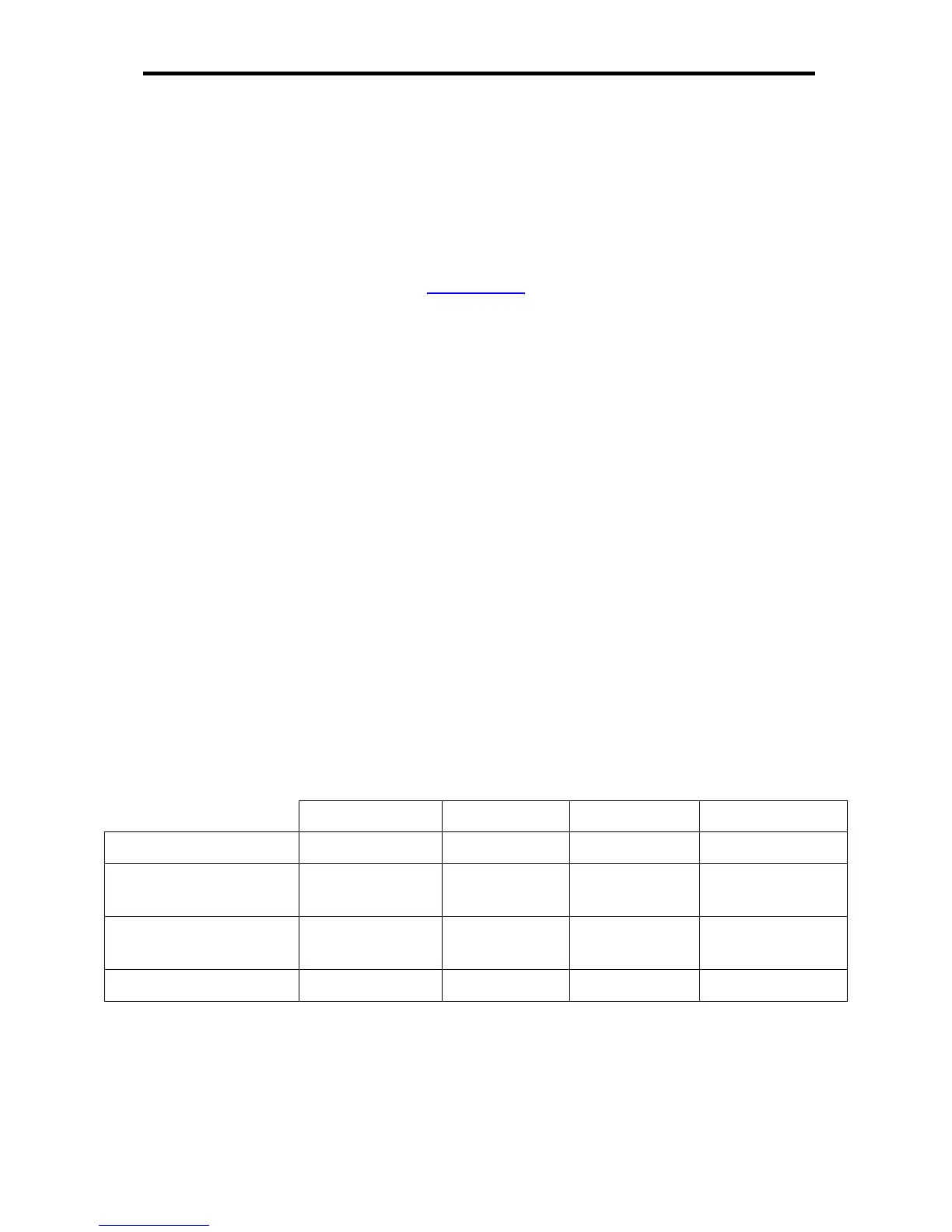

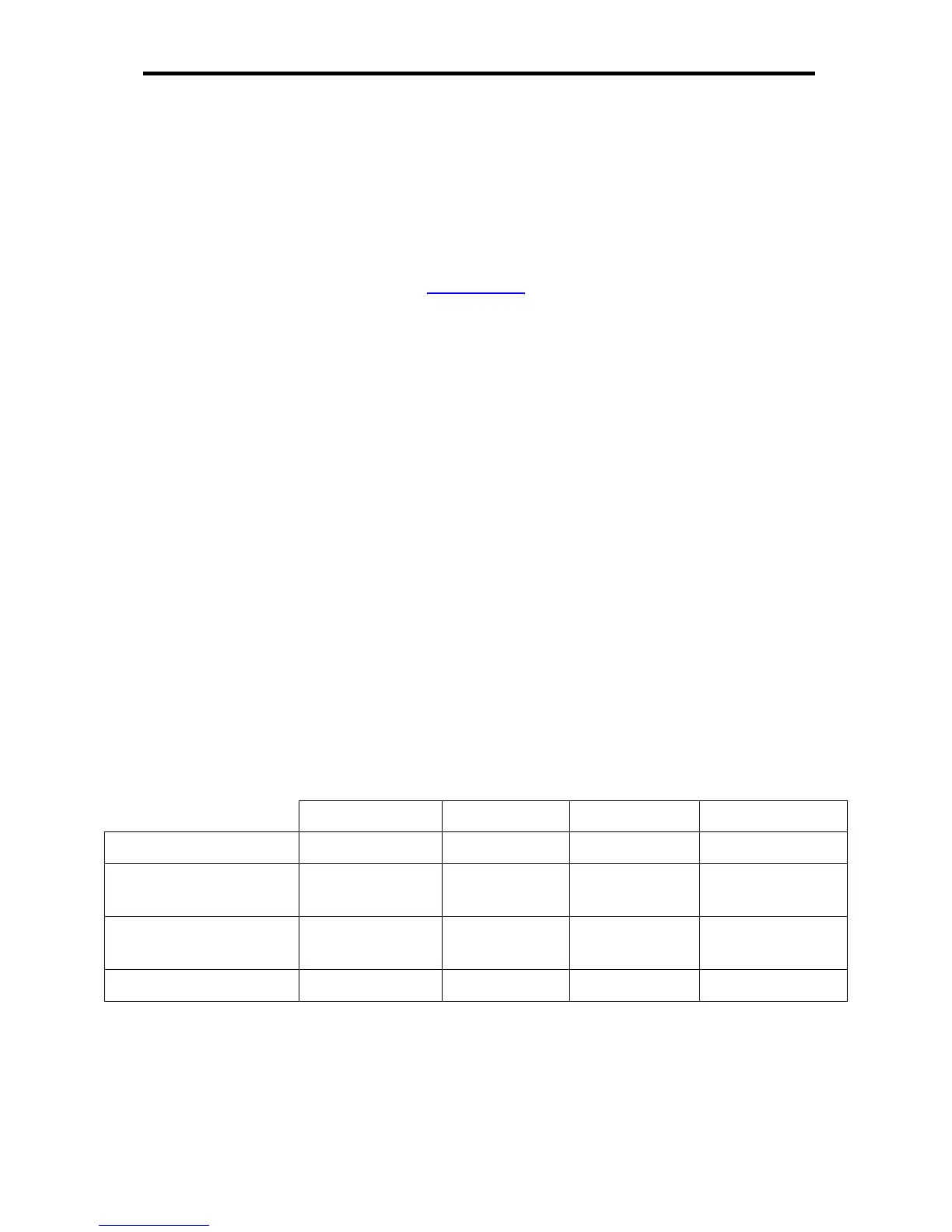

Units Maximum Typical Minimum

Process Water Pressure PSIG (Bar)

125 (8.6) N/A 5 (0.35)

Process Water Daily

Consumption

Gallons (Liters)

5.0 (19) 1.5 (5.7) 0 (0)

Condensate Production

per Day

Gallons (Liters)

5.0 (19) 1.5 (5.7) 0 (0)

Sump Water Volume Gallons (Liters)

15 (57) 15 (57) 6.6 (25)

Process Water Inlet

Connect a clean water supply line through an external customer-supplied hand valve to

the Process Water Inlet connection on the rear of the conditioner; this is a ½” male NPT

connection.

Loading...

Loading...