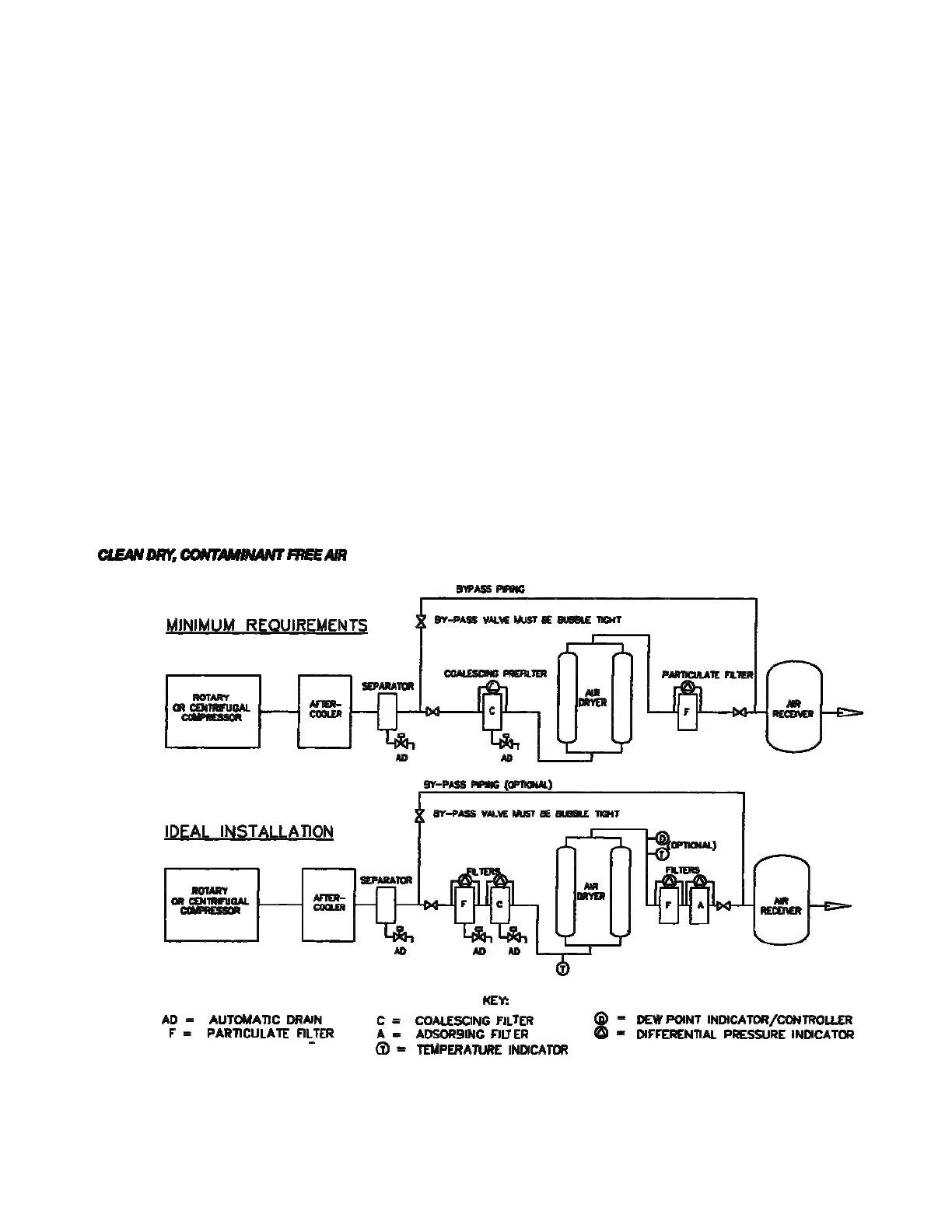

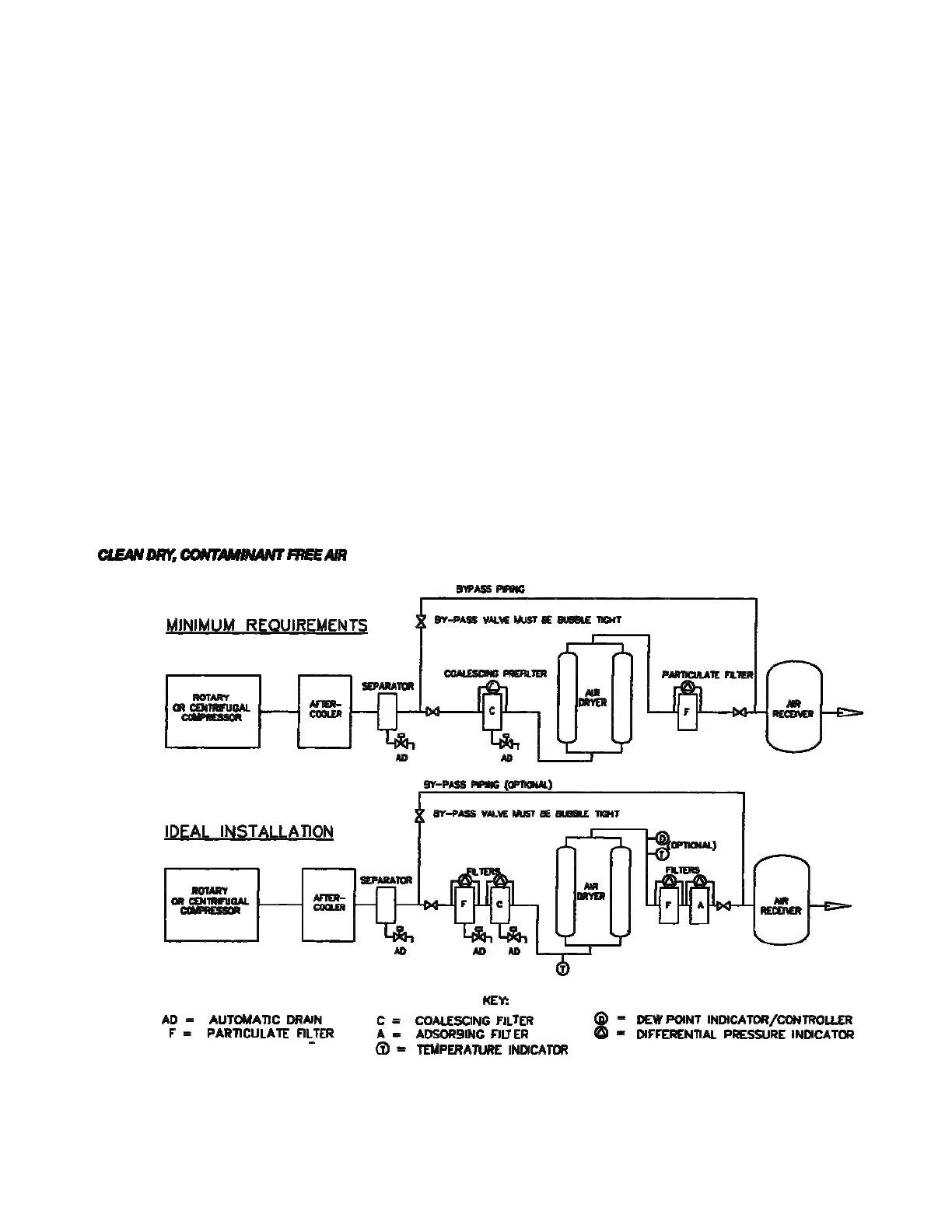

5. IMPORTANT! Bypass piping is necessary. A bubble tight valve should be used for bypass

around filters and dryer for servicing.

6. Make required electrical connections to control box. Refer to applicable drawings.

NOTE: Customer to provide short circuit protection for dryer.

7. Access ports should be provided upstream and down- stream of the dryer for dew point, pressure,

and temperature checks. Periodic checking of the dew point just downstream of the dryer is the best

indication of whether the dryer is performing as expected. A High Humidity Alarm or Powerloc are

available as options.

8. All piping should be adequately supported and at least of equal size to the dryer connections.

9. To reduce maintenance and increase dryer efficiency, the exhaust ports can be piped to a location

where the exhaust mufflers are not required. The piping MUST NOT create any back pressure on the

regenerating tower and must be up-sized accordingly. It is recommended that the exhausts be piped

separately for ease of troubleshooting and maintenance.

Before any attempt is made to operate the AIRTEK dryer, the operator should thoroughly read and

understand this instruction manual. Improper operation will cause poor results from the dryer.

Recommended Installation

Loading...

Loading...