14

Proportional Pressure Valves

Series RE*T / R*V

Operation Manual

Parker Hannifin Corporation

RE_-R_V obe_24-45-A-B 5715-651 UK 29.01.19

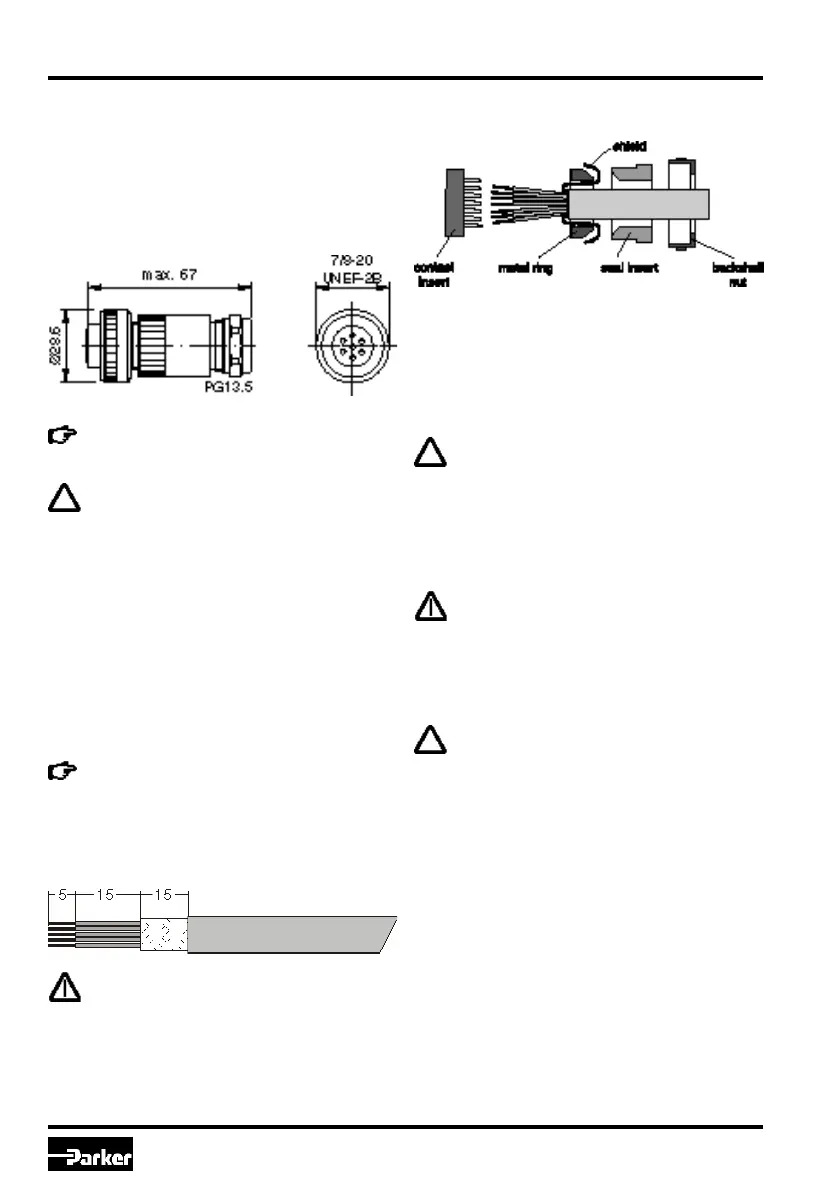

Electrical Connection

The electrical connection of the valve takes place

by one common cable, which is coupled to the

integrated electronic driver by a central connector

assembly.

The connection requires a 6 + PE female connector

EN 175201-804.

The female connector has to be ordered

separately under article nr. 5004072.

A female connector with metal housing is

required! Plastic made models may create

function problems due to insufficient EMC-

characteristics.

The connecting cable has to comply to the following

specification:

Cable type control cable, flexible,

7 conductors, overall braid

shield

Cross section min. AWG16/1.0 mm

2

Outer dimension 8...12 mm

Cable length max. 50 m

For cable lengths > 50 m consult factory.

The connection cable is coupled to the female

connector by solder joints.

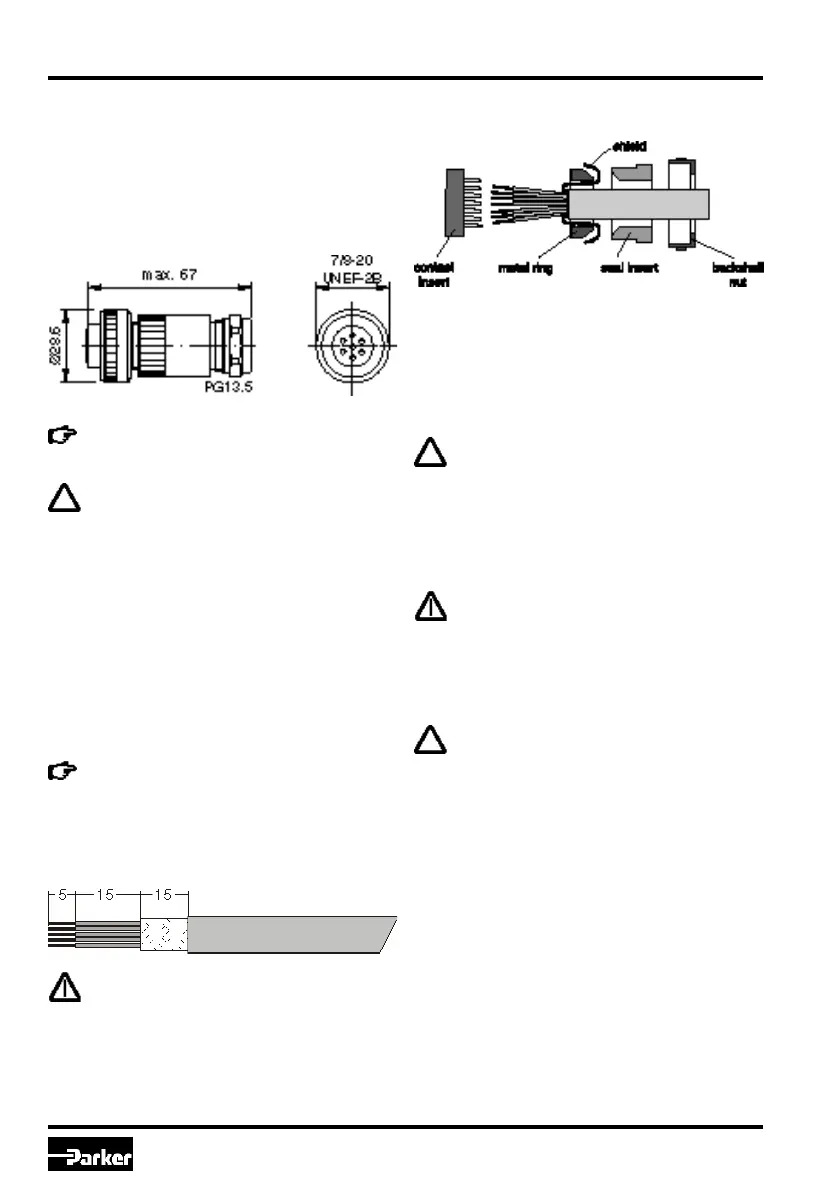

Skinning lengths for the connecting cable:

The shielding has to be assembled according the

outline below:

The backshell nut of the cable gland has to be

tighten with a suitable tool. The target value for the

tightening torque is 4 Nm. Tighten the cap nut with

a torque of approx. 5 Nm after attaching the female

connector on the socket outlet.

Incomplete tightening of backshell nut resp.

cap nut may result in automatic release of

the connection as well as degradation of the

water tightness.

Follow the “instructions for use“ for installation

of female connectors made by other kind of

brands!

The cable connection to the female connector

has to take place by qualified personnel! A

short between individual conductors resp. to

the connector housing , bad soldering as well

as improper shield connection may result in

malfunction and breakdown of the valve.

The mounting surface of the valve has to be

tied to the earth grounded machine frame. The

earth ground wire from the valve connecting

cable as well as the cable shield have to be

tied to the protective earth terminal within the

control unit. It is necessary to use a low ohmic

potential connection between control unit and

machine frame to prevent earth loops (cross

section AWG 6).

Do not disconnect cable socket under tensi-

on!

Loading...

Loading...