Proportional Pressure Valves

Series RE*T / R*V

Operation Manual

21

Parker Hannifin Corporation

RE_-R_V obe_24-45-A-B 5715-651 UK 29.01.19

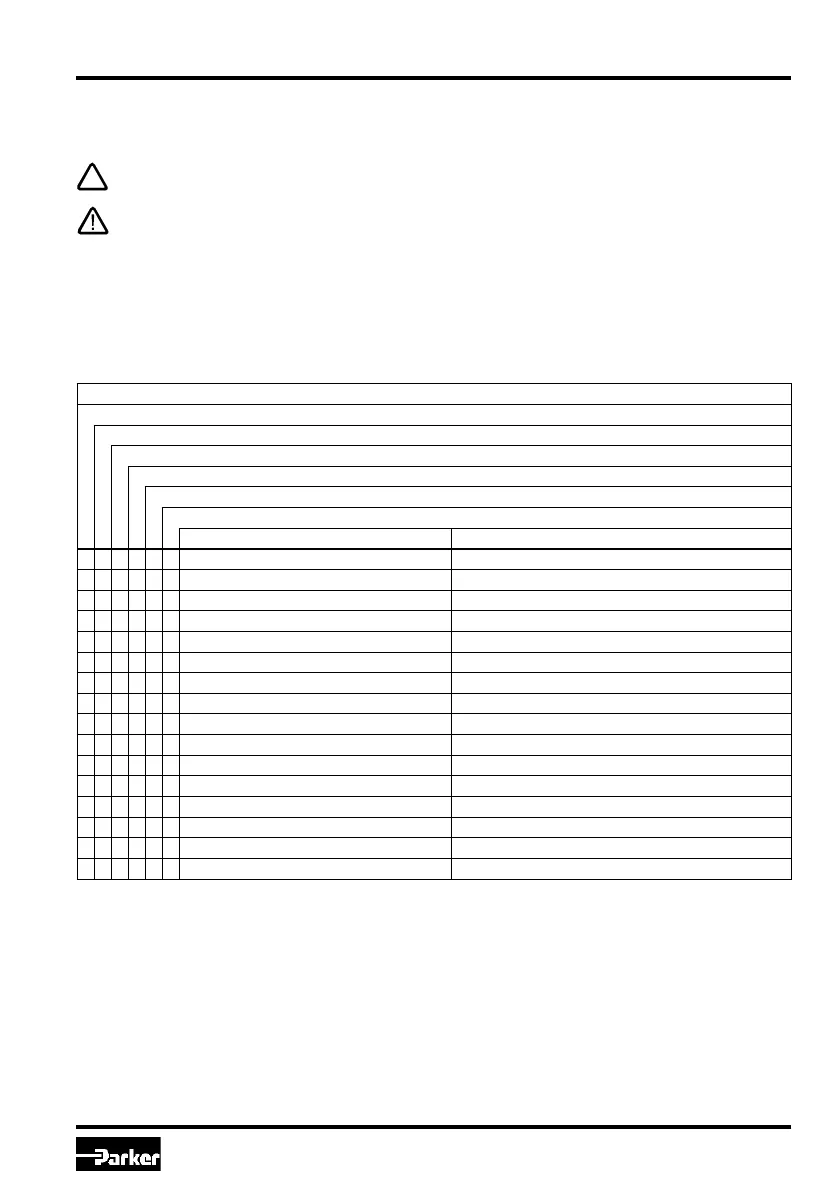

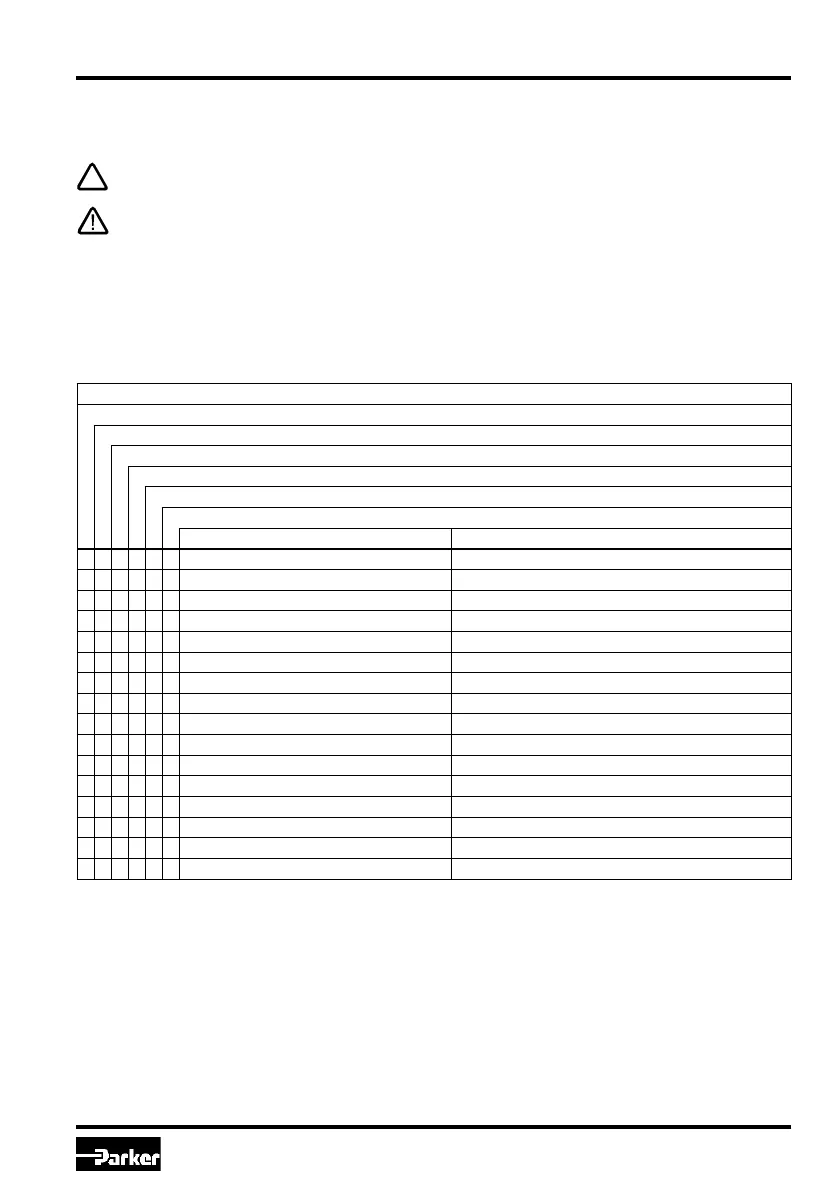

malfunction at hydraulic load runtime

- generally no function

- high frequent oscillation

- low frequent oscillation

- pressure at unchanging command

- pressure too low

- drifting without command

possible reasons for malfunction corrective actions

x hydraulic pump resp. motor defective replace hydraulic pump resp. motor

x x x x drive overloaded reduce pressure resp. speed, increase valve size

x x x x x valve contaminated clean pressure fluid, filter / flush valve

x x hydraulic fluid too viscous / too cold change fluid grade, provide operational temperature

x x too low oil level within tank refill pressure fluid

x x filter contaminated replace filter

x x x x supply voltage too low keep supply voltage range

x supply voltage carries too much ripple reduce ripple

x x command signal too low increase command signal

x command signal carries too much ripple reduce ripple

x dither signal amplitude too high reduce parameter P5

x dither signal amplitude too low increase parameter P5

x x x x x central connector contact failure clean contacts resp. replace connector

x feed cable interrupted fix feed cable

x x x x x x wiring sequence incorrect correct wiring sequence

x x feed cable without shielding change cable grade

6. Trouble Shooting

Basis of troubleshooting is always a systematic

approach.

For suspect of a sluggish spool the valve may

be flushed with clean pressure fluid.

Troubleshooting in a hydraulic system requires

detailed knowledge about function and

construction of the system. Therefore the work

may exclusively be performed by qualified

personnel.

Loading...

Loading...