Bulletin 100-50-5.2 – Page 13

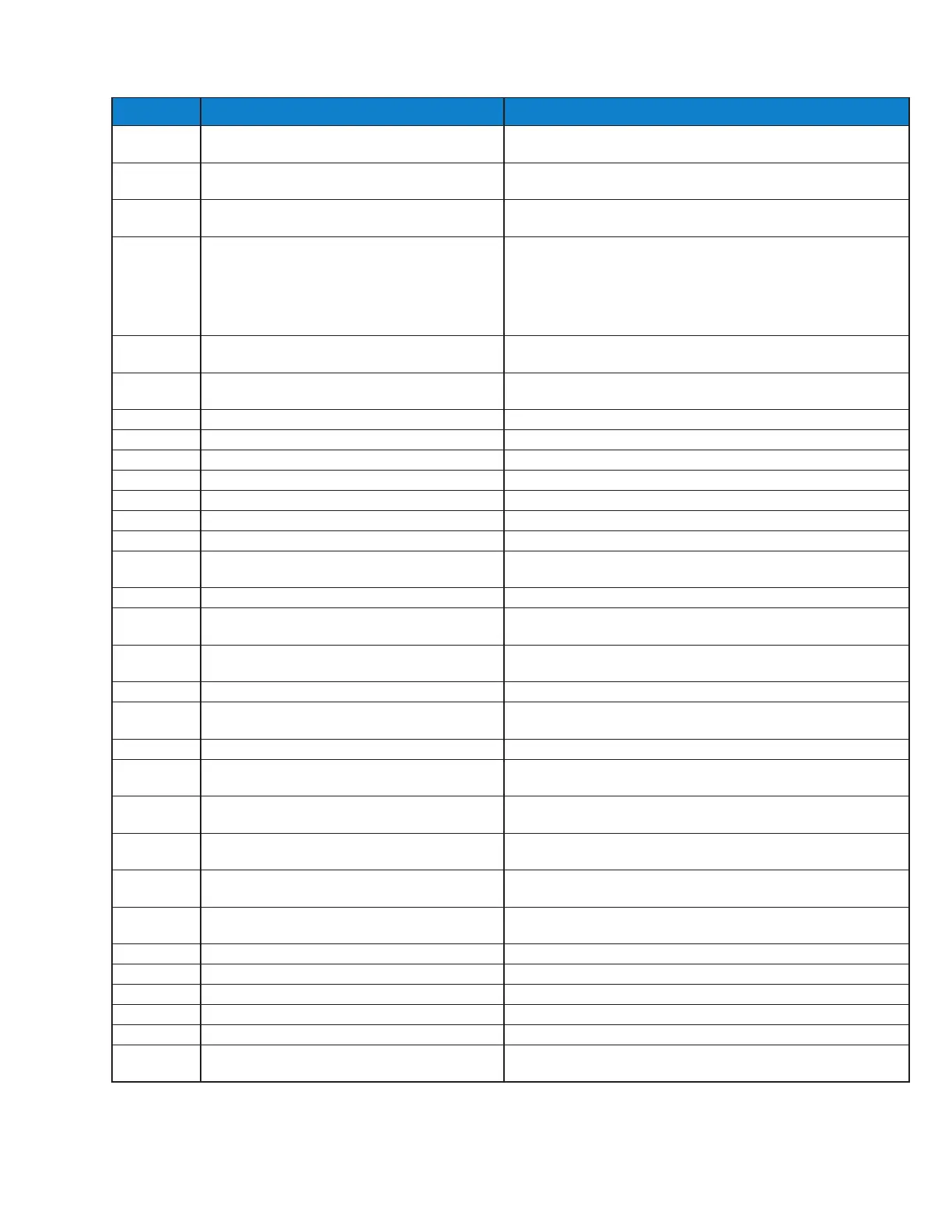

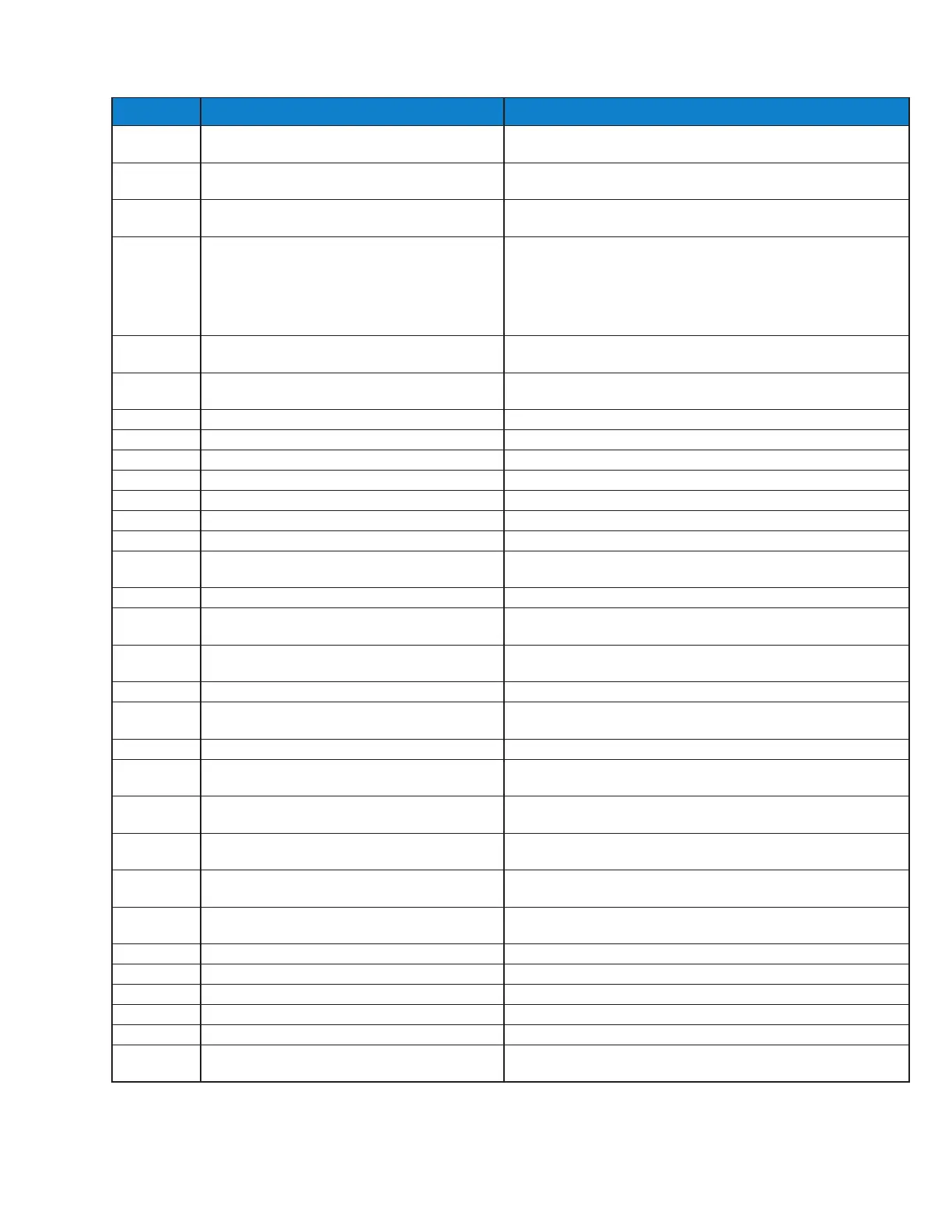

APPENDIX F - Parameter Definitions

DISPLAY MEANING DESCRIPTION

ESC

Escape

Escape from the Settings Menu and Return to Process

Variables Menu

LoSP

Liquid Outlet Temperature Control Setpoint

The target control temperature of the liquid leaving the

heat exchanger

rghL

Return Gas High Limit

Limits the temperature of the superheated refrigerant to a

maximum target value (Limits superheat PID target)

SboF

Subcooler Off Temperature Differential

Temperature differential above the liquid outlet tempera-

ture setpoint that the liquid inlet temperature must fall

below in order to switch to OFF mode. Will switch back to

cooling after the liquid inlet temperature rises above the

liquid outlet temperature + subcooler off temperature

differential + 5 degrees F

SHSP

Superheat Setpoint

The minimum target superheat setpoint that the superheat

PID can try to maintain

rEFr

Refrigerant

The currently selected refrigerant used to calculate the

saturation temperature based on suction pressure

HiCP

Maximum Stepper % Open The maximum % open of the valve referenced to full stroke

-LP-

Liquid Proportional Gain Coefcient Liquid Proportional Gain Coefcient

-L-

Liquid Integral Gain Coefcient Liquid Integral Gain Coefcient

-Ld-

Liquid Derivative Gain Coefcient Liquid Derivative Gain Coefcient

-SP-

Superheat Proportional Gain Coefcient Superheat Proportional Gain Coefcient

-S-

Superheat Integral Gain Coefcient Superheat Integral Gain Coefcient

-Sd-

Superheat Derivative Gain Coefcient Superheat Derivative Gain Coefcient

LSHi

Low Superheat Integral Gain Coefcient

The integral gain coefcient to use for the superheat PID

loop if the superheat is below 3 degrees F

CyCt

Cycle Time The PID update time

StEP

Stepper Type

The number of steps of resolution for the stepper valve at

full stroke

SPoS

Manual Stepper Position

Overrides the stepper valve position and moves to the

desired percent open relative to full stroke of the valve

Addr

Network Address The address of the controller on the MODBUS network

bAvd

Network Baud Rate

The baud rate in hundreds of bits per second of the MOD-

BUS network

nPAr

Network Parity Mode The network parity mode of the MODBUS network

nP

Units of Pressure

The units of pressure the controller uses to display (PSI or

Bar)

nt

Units of Temperature

The units of temperature the controller uses to display

(Fahrenheit or Celsius)

tt4P

Temperature Sensor Type

The type of thermistor connected to the controller (2K type

or 3K type)

Pt4P

Pressure Sensor Type

The type of pressure sensor connected to the controller

(absolute or gauge type)

Prng

Pressure Sensor Range

The range of the pressure sensor connected to the control-

ler (0-150 PSI, 0-300 PSI, or 0-500 PSI)

CALP

Pressure Calibration Offset Adds a constant offset to the pressure reading

CLt1

T1 Temperature Calibration Offset Adds a constant offset to the T1 temperature reading

CLt

T2 Temperature Calibration Offset Adds a constant offset to the T2 temperature reading

CLt3

T3 Temperature Calibration Offset Adds a constant offset to the T3 temperature reading

CLt4

T4 Temperature Calibration Offset Adds a constant offset to the T4 temperature reading

Cadr

Controller Address on Display Network

Controller must be set to 0 (Standalone) No display net-

working option

Loading...

Loading...