28

Every six months:

1. Make a visual inspection of all moving parts for possible wear, interference or

damage.

2. Check and adjust as necessary, equalizer tension of the cables to insure level

lifting.

3. Check the vertical of columns.

4. Check rubber pads and replace as necessary.

5. Check safety device and make sure proper condition.

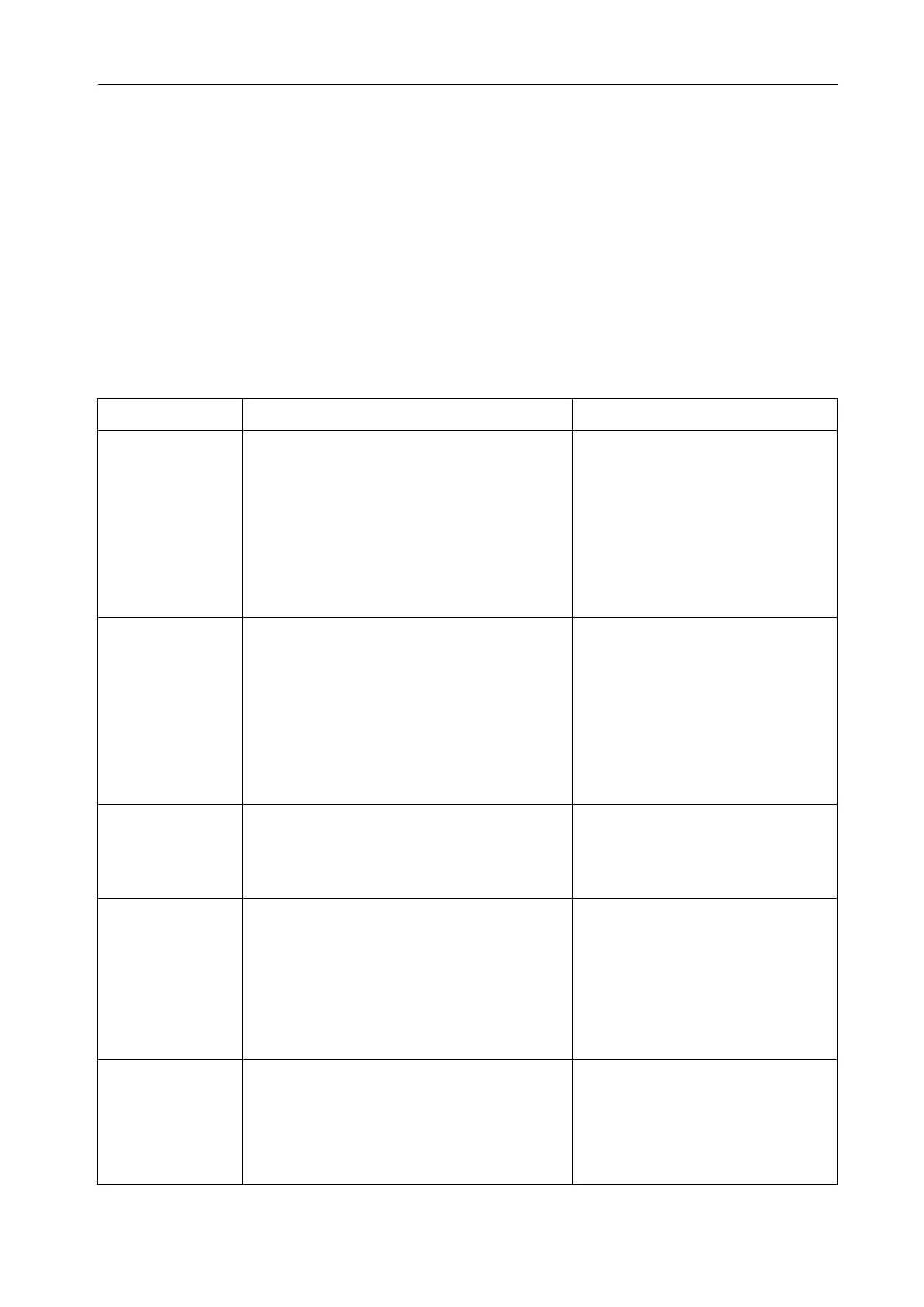

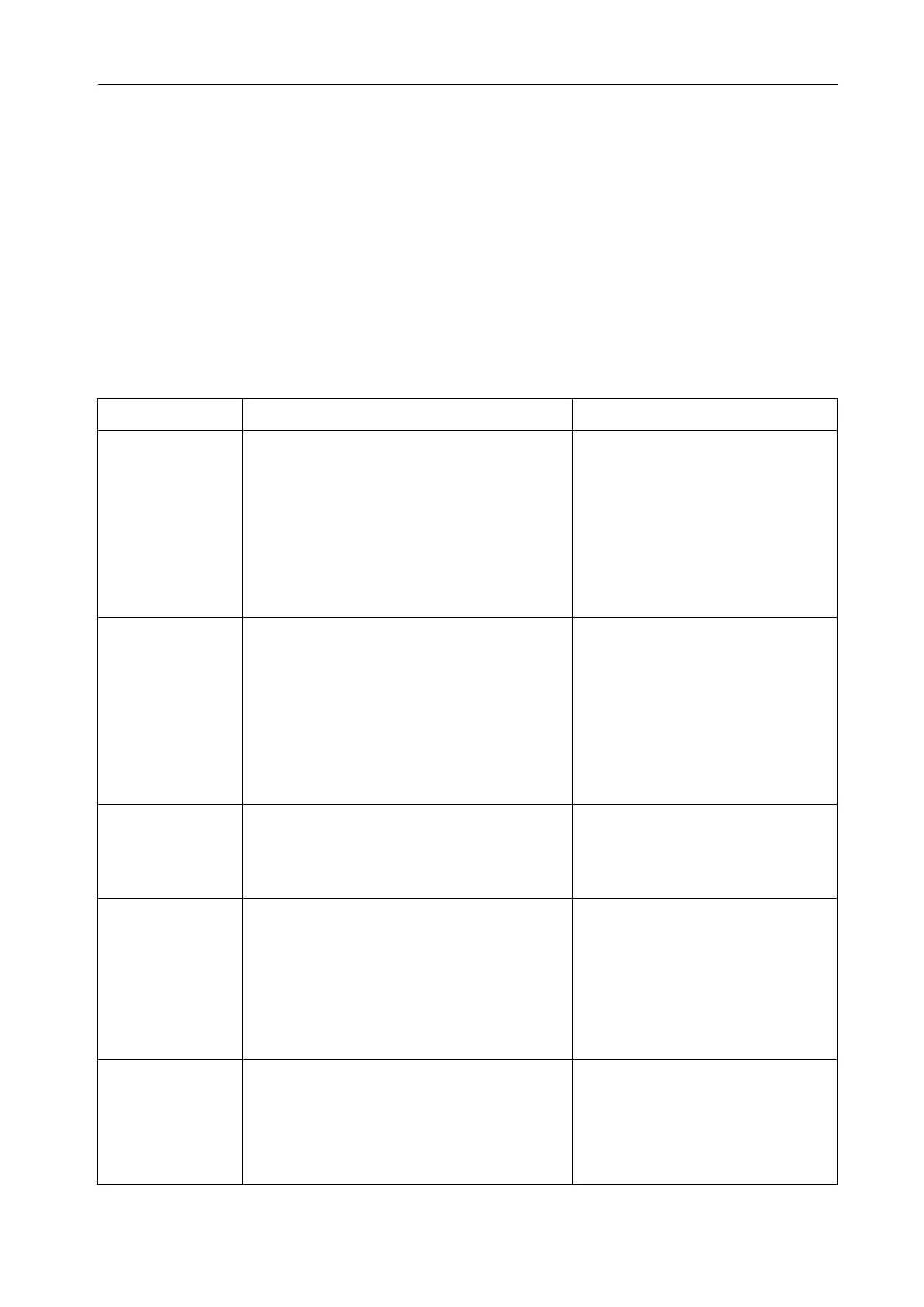

VIII.TROUBLE SHOOTING

1. Button does not work

2. Wiring connections are not in good

condition

3. Motor burned out

4. Height Limit Switch is damaged

5. AC Contactor burned out

1. Replace button

2.Repair all wiring connections

3. Repair or replace motor

4.Replace the Limit Switch

5. Replace AC Contactor

Motor runs but

the lift is not

raised

1. Motor runs in reverse rotation

2. Gear Pump out of operation

3. Release Valve in damage

4. Relief Valve or Check Valve in

damage

5. Low oil level

1.Reverse two power wire

2.Repair or replace

3. Repair or replace

4.Repair or replace

5.Fill tank

1. Release Valve out of work

2. Relief Valve or Check Valve leakage

3. Cylinder or Fittings leaks

1. Oil line is jammed

2. Motor running on low voltage

3. Oil mixed with Air

4. Gear Pump leaks

5. Overload lifting

1. Clean the oil line

2. Check electrical system

3. Fill tank

4. Replace Pump

5. Check load

1. Safety device are locking

2. Release Valve in damage

3. Safety cable broken

4. Oil system is jammed

1. Release the safeties

2. Repair or replace

3. Replace

4. Clean the oil system

Loading...

Loading...