10

2005 Doctor Martin Luther King Jr Street

Indianapolis, IN 46202

Rev 07-2021

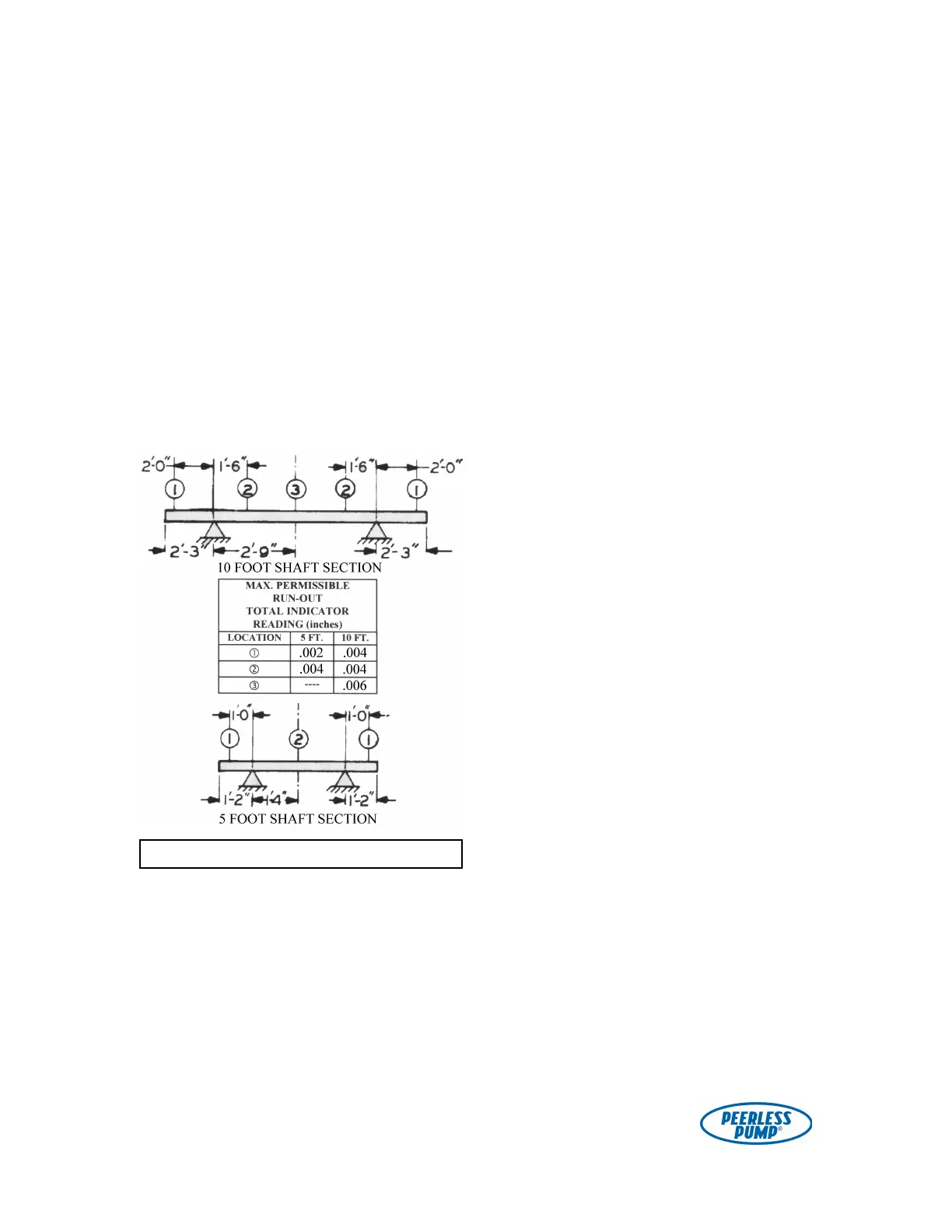

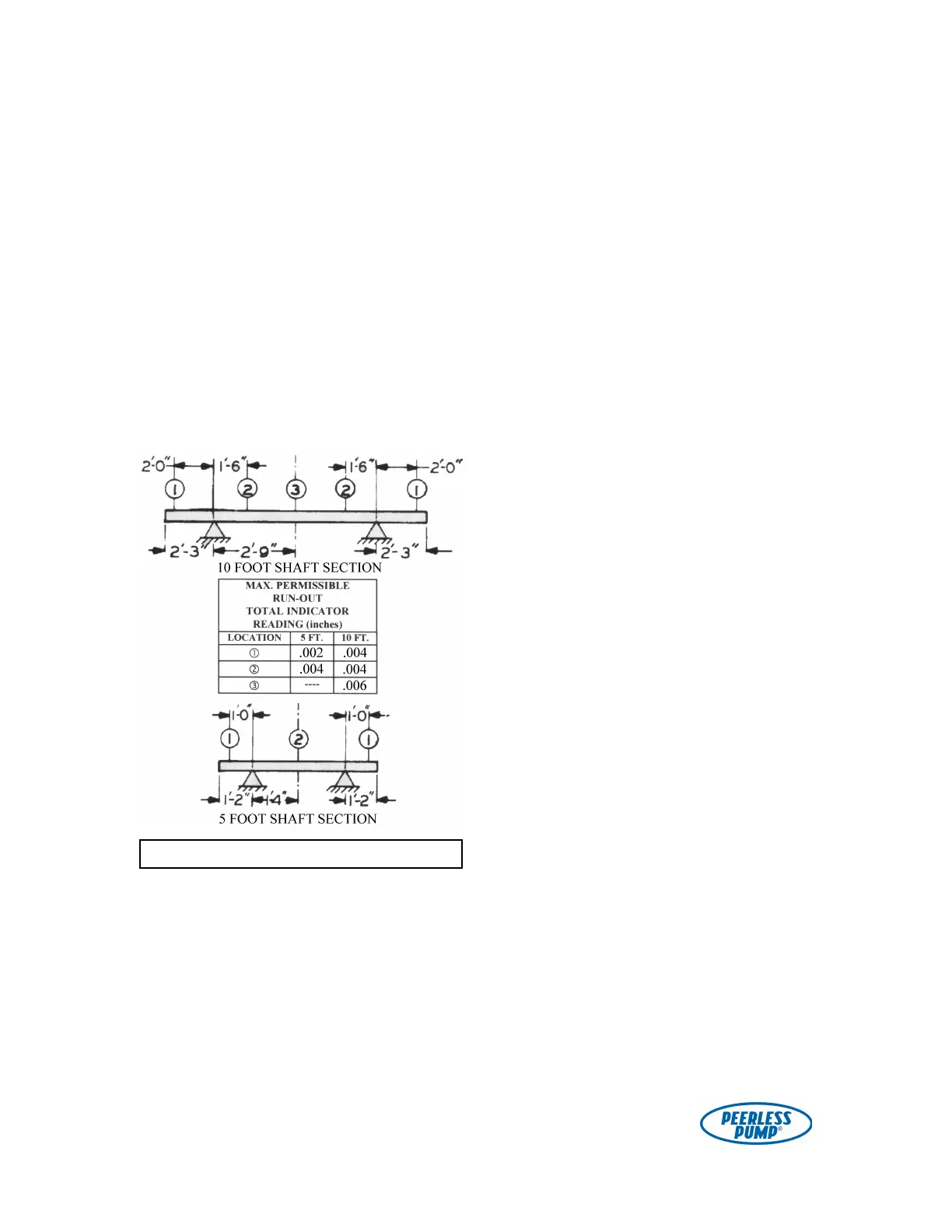

Preparation of shaft sections:

Before beginning the installation of

the shaft sections, inspect them for

straightness: verify that they have not

been bent in shipping or handling. Set a

pair of rollers or vee-blocks on a firm

base next to the pump site to support one

shaft section as shown in Fig. 2.

Provide a solid mounting for a dial

indicator at the points labeled 1, 2, and 3

in Fig. 2. Place a shaft on the rollers or

vee-blocks and rotate it slowly by hand

while checking the eccentricity (run-out)

at points 1, 2 and 3.

Check all of the shaft sections in

this manner. Do not use any shaft

section that exceeds the limits given in

Fig. 2. Rejected shaft sections may be

straightened.

All re-straightened shaft sections

must have a cleanup cut machined on

both ends. Re-straightened shaft

sections must be rechecked for

eccentricity.

Larger shafts and shafts for non-

threaded (split-ring) couplings may have

an internal threaded section on one end;

this end goes up. In a flanged column

pump, the intermediate column sections

have identical ends; either end may be

upward. However, the top and bottom

sections may not have identical ends.

Refer to the assembly drawing for the

proper orientation.

The preferred method is to install

the shaft and couple it, then install the

tube and column over the shaft--

provided that head room permits. If

head room is limited, insert the shaft and

tube sections into the column sections so

that the shaft extends about a foot above

the top end of the column. This will

make it convenient for tying later.

When inserting the shaft and tube

sections into the column sections, take

care not to bend the shaft or damage

the threads.

Figure 2. Verification of

Loading...

Loading...