23

2005 Doctor Martin Luther King Jr Street

Indianapolis, IN 46202

Rev 07-2021

After the discharge head is installed

on the pump column, always use the

lifting ears on the discharge head for

hoisting the pump. If the discharge head

does not have lifting ears, pass the slings

through the hand holes, taking care that

the slings do not interfere with the shaft.

Never attempt to lift the pump by

means of eyebolts screwed into the

driver mounting holes because the

bolts are not strong enough to carry

the weight of the entire pump.

LEVELING THE PUMP

Remove the supporting timbers,

rope and any other equipment from the

top of the foundation. Cover the

discharge head to protect it from dust,

and sweep the foundation clean.

If the sole plate is not already

grouted in place, be certain that the

grouting dam around the foundation

opening is in place before lowering the

pump assembly onto the foundation.

Lower the pump until the base of

the discharge head or sole plate is just

above the foundation bolts; then orient

the pump so that the discharge outlet is

in the desired direction and the holes in

the base align with the foundation bolts.

Continue to lower the pump until the

bolts just enter the holes in the base.

If the foundation is concrete, place

the wedges (furnished with the pump)

under the discharge head or sole plate,

adjacent to the bolt holes, one under

each of the four sides. For structural

foundations (made up of I-beams or H-

beams), use flat shims under the corners.

Continue to slowly lower the pump

until the base of the discharge head or

sole plate rests on the shims or anchor

bolts with washers and nuts.

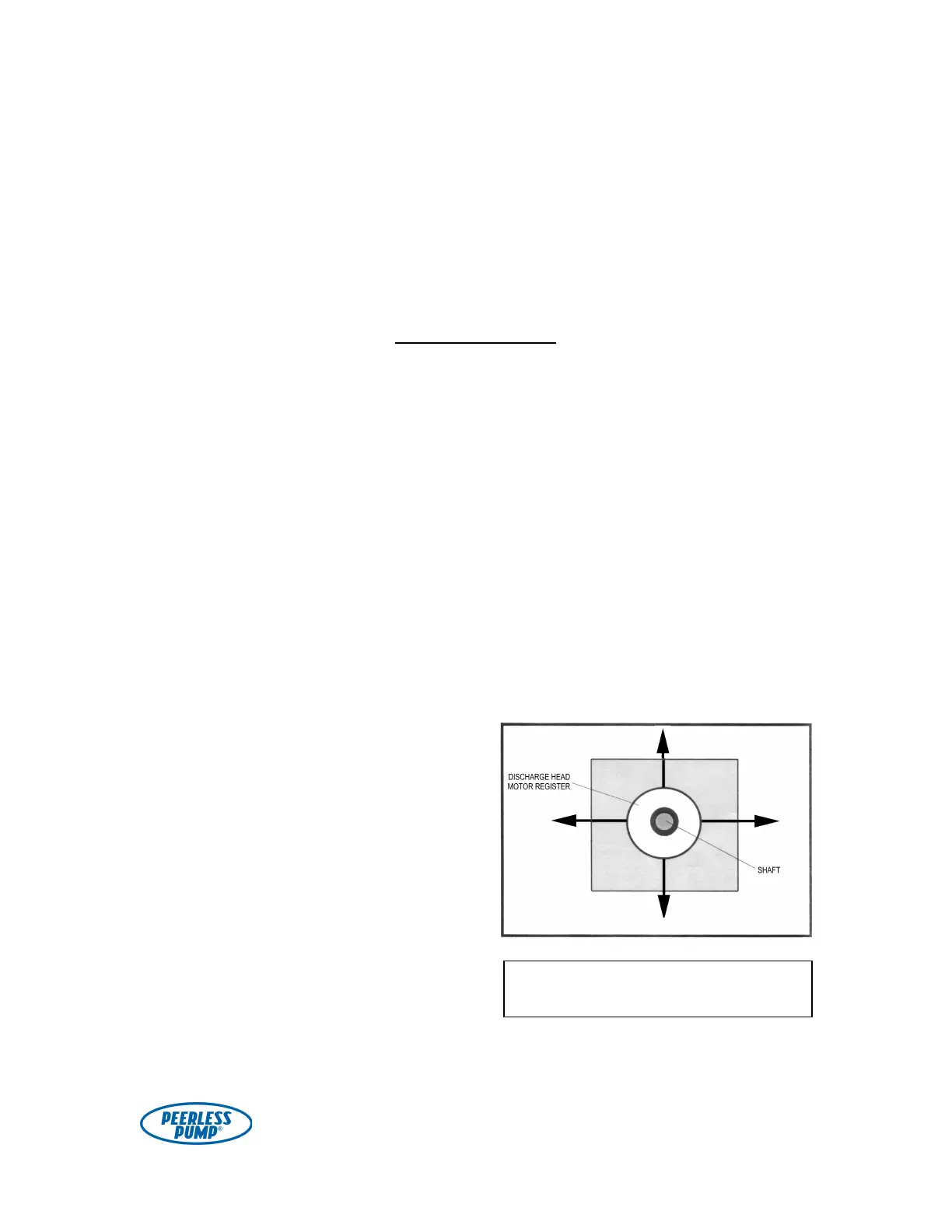

Accurate alignment of the discharge

head in relation to the pump shaft is

absolutely essential for a smoothly-

operating and trouble free pumping

system.

By using the wedges or washers and

nuts on the anchor bolts, adjust the

discharge head flange centerline to the

correct elevation.

While maintaining the correct

elevation, adjust the nuts and washers or

shims to achieve the specified levelness

(0.0005" per foot) in both directions, as

shown in Figure 16. The levelness

should be measured by placing a

precision level on the machined face of

the discharge head motor register.

Figure 16. Check for levelness in two

directions.

Loading...

Loading...