25

2005 Doctor Martin Luther King Jr Street

Indianapolis, IN 46202

Rev 07-2021

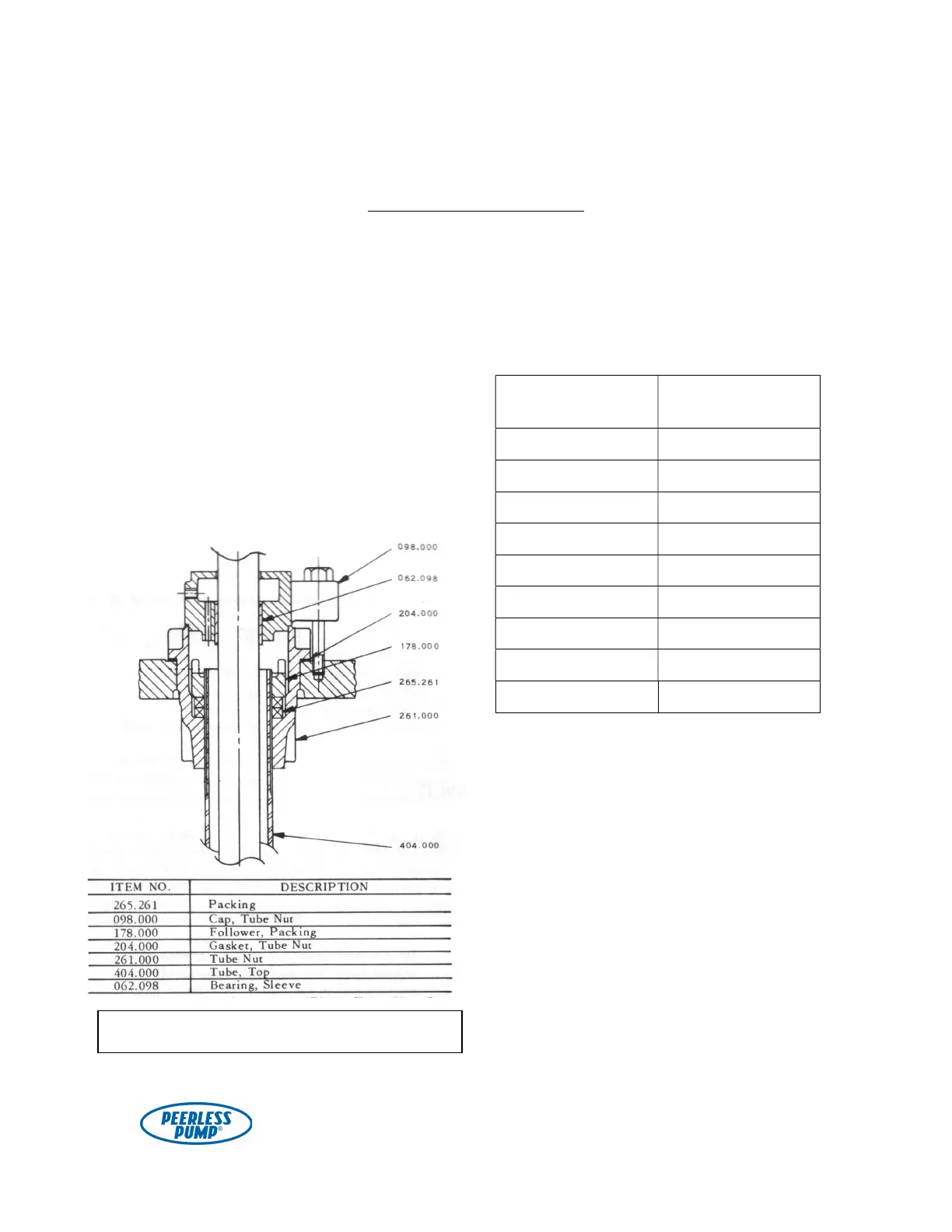

TENSIONING THE TUBE NUT

The enclosing tube sags slightly

from its own weight as it is installed, and

must be pulled tight (tensioned) to make

it straight. The tube nut (see Fig. 15)

holds the tube in its straightened

position. This section describes two

methods of tensioning the tube. The

second method (the “wrenching

method”) is given as an alternative for

use with pumps having settings less than

500 feet.

Note: The correct tension is the

weight of the enclosing tube plus 10%.

Weights-per-foot for each tube size

are given in Table 2. Multiply by the

total length of tube to determine the total

weight.

Table 2. Weight per Foot of

Enclosing Tube

Tube size (in.) Weight per foot

(lb.)

1 ¼ 2.99

1 ½ 3.63

2 5.02

2 ½ 7.66

3 10.25

3 ½ 12.50

4 14.98

5 20.78

6 28.57

Apply a generous coating of grease

to both sides of the gasket and place the

gasket on the discharge head. Install the

tube nut, screwing it down manually

until its shoulder rests firmly on the

gasket.

The upper end of the tube may be

pulled by the hoist to obtain the

predetermined tension value. This

requires the use of a dynamometer scale

and a specially-made fitting to grip the

tube. The fitting may be a short tube

with welded-on lugs for gripping with a

sling and an internal thread to mate with

the tube thread.

Figure 17. Typical tube nut assembly.

Loading...

Loading...