11

2005 Doctor Martin Luther King Jr Street

Indianapolis, IN 46202

Rev 07-2021

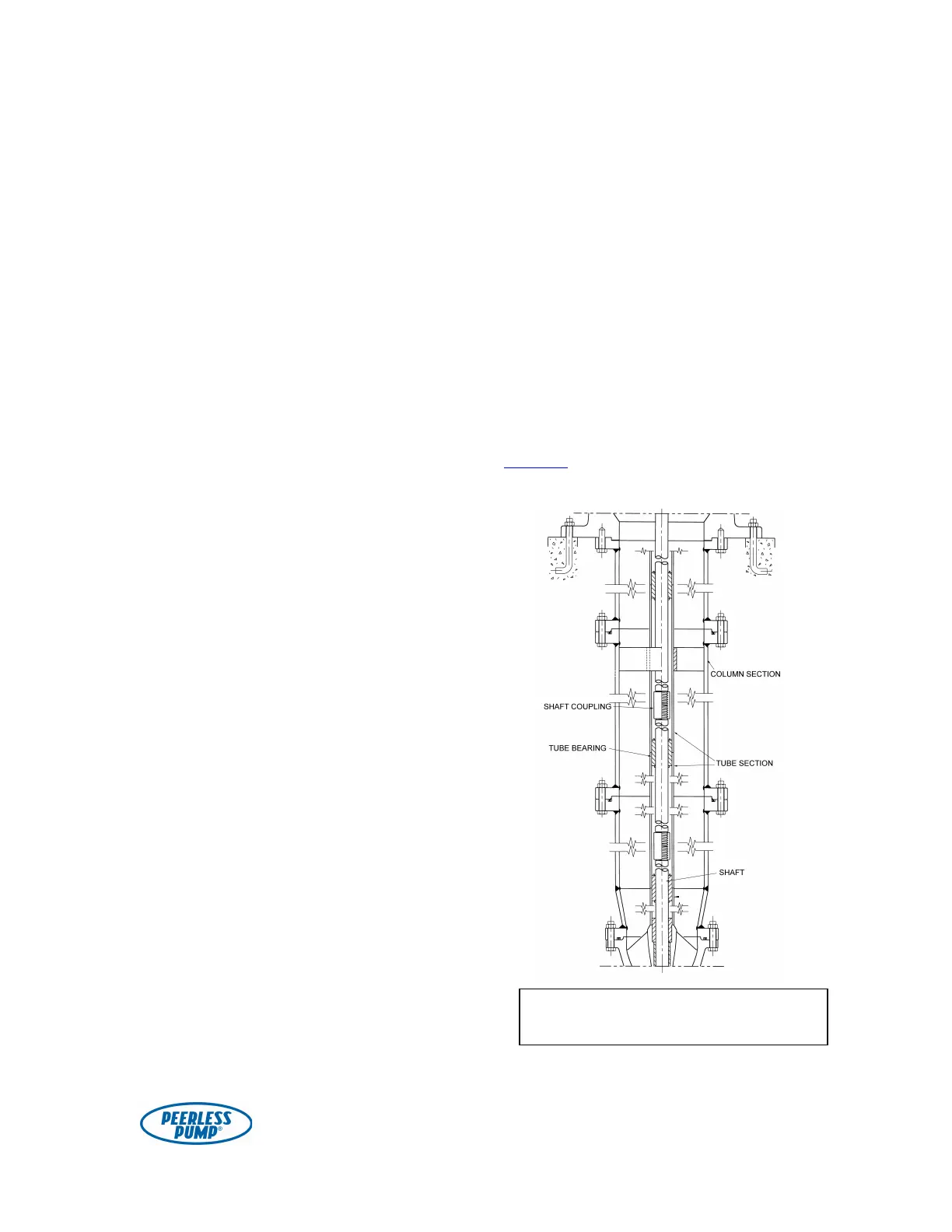

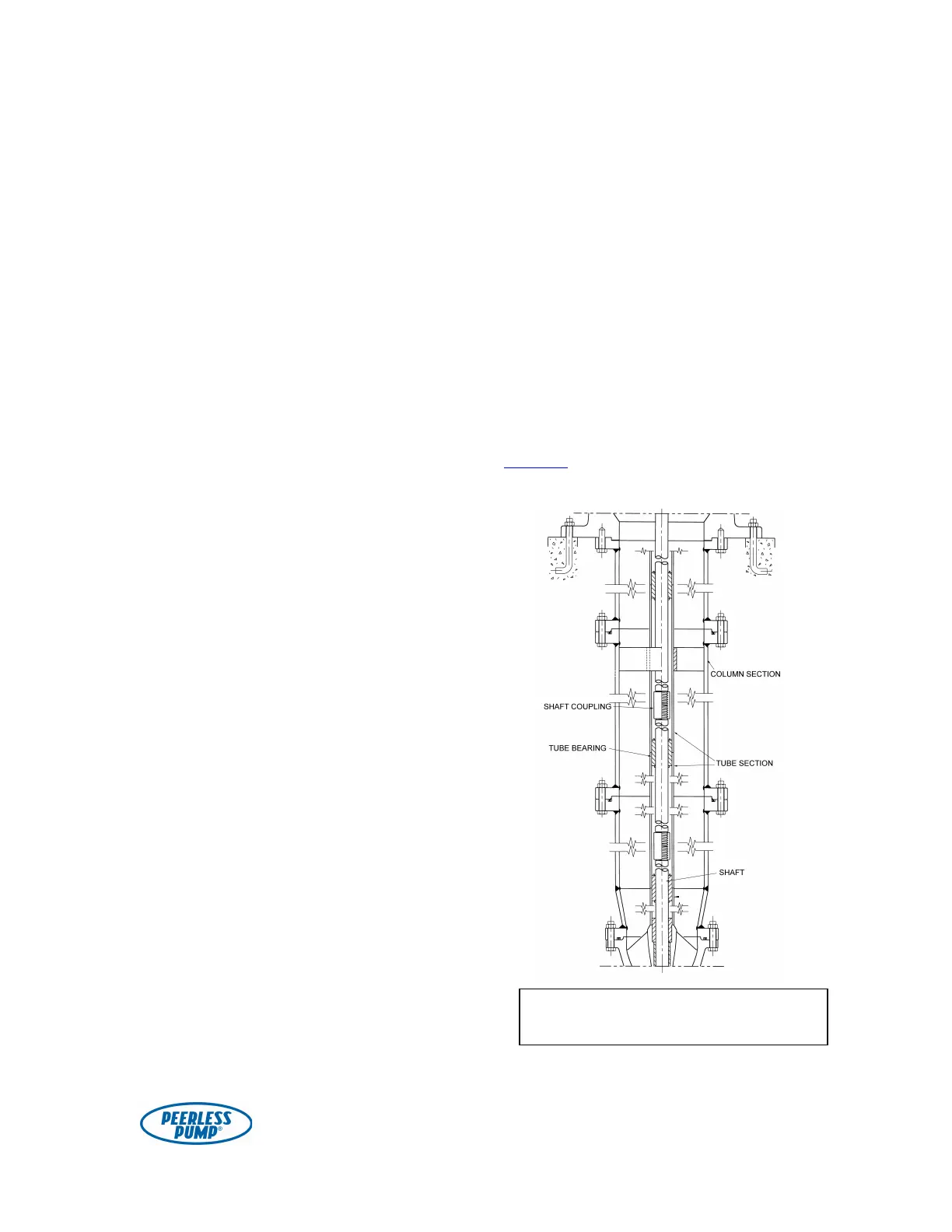

Preparation of tube sections:

Prior to assembling the tube

sections, inspect the tube faces to ensure

that they are free of nicks or burrs. Any

flaws on the tube end faces must be

removed prior to assembly, to ensure

proper mating of tube surfaces.

The tube sections are coupled by

tube bearings. Lubricate tube bearing

threads. Assemble the tube bearing onto

one tube, threading it in one-half of its

total length. Tube sections are furnished

in two different lengths: ten feet and

twenty feet. The ten-foot sections are

actually two five-foot sections, internally

threaded and coupled by an externally

threaded tube bearing; likewise, the

twenty-foot sections consist of four

coupled five-foot sections (see Fig. 3).

The top tube section is different and

may be identified by the external thread

at the upper end. It may be one piece or

coupled by means of a threaded tube

bearing to a “second top tube”

combining for a length that may be

different than the standard section

lengths. The tube section just below the

top tube is shorter than standard—

usually 3′4″. The top column section is

never fitted with a coupling, since the

upper end screws directly into the

discharge head or into a special flange.

While the bowl assembly is still in a

horizontal position, push the shaft down

as far as it will go and measure the

distance from the top bowl flange to the

top of the shaft. The normal

measurement is 20″. The distance from

that same flange to the top of the tube

adaptor face should be 10″. This

dimension is frequently referred to as

“10/20 stickup”.

If the dimensions on the bowl assembly

are different than those stated above, do

not proceed with installation; contact a

Peerless Pump representative as there

may be special instructions for your

bowl assembly.

Having recorded the first

measurement, now pull the shaft toward

you (or up) as far as you can and take a

second measurement. The difference

between the first and second

measurements is the total axial

movement of the impeller. This

clearance is normally ½″ ± ⅛″ (see

Table 4 on pages 37-39 for specific

dimensions).

Figure 3. Sectional view through

enclosed lineshaft column.

Loading...

Loading...