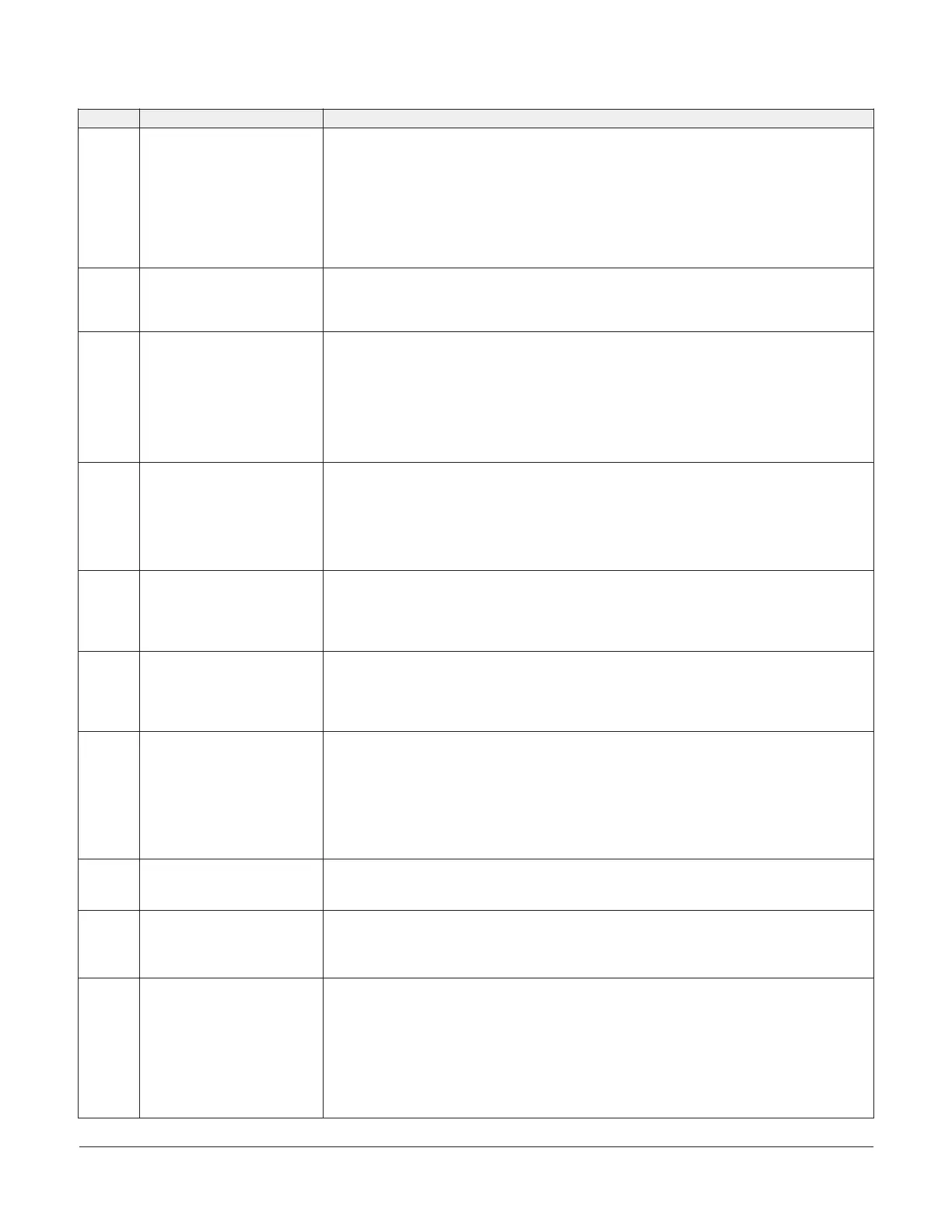

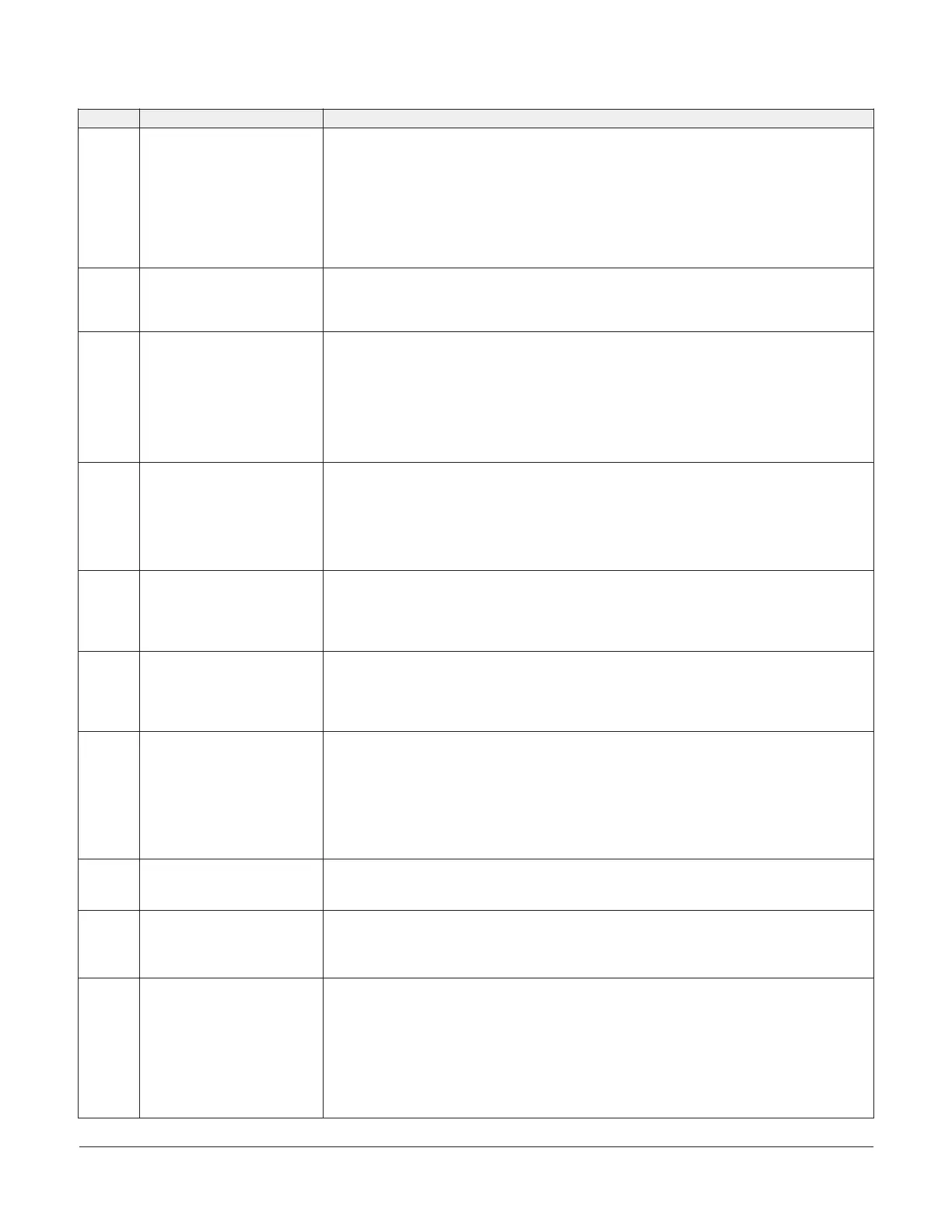

Table 10: System 450 web UI Analog Output Configuration page user actions, descriptions, and references

Callout Identifier item name User actions, descriptions, references

4 SENS (Reference Sensor) Click the drop-down menu to select the sensor that this output references. The reference

sensor selected for this output is displayed in this field.

If Sn-1 and Sn-2 have the same sensor type, the Sn-d and HI-2 sensors are available for

selection. If Sn-1, Sn-2, and Sn-3 have the same sensor type, the Sn-d, HI-2 and HI-3 sensors

are available for selection.

After a sensor is selected for the output, the sensor number is displayed in the field, along

with the sensor’s sensor type and the usable range of values.

In this example, Sn-1 is the selected reference sensor and Sn-1 is configured as a P 500 sensor

type, which provides a 90 to 500 psi range.

5 Sensor name Displays the assigned sensor name.

You can assign a 16-character (maximum) name for each sensor that you set up on the

Sensor Configuration page.

See Sensor Configuration Page for more information on assigning sensor names.

6 SP (Setpoint) Enter the desired SP (Setpoint) value for the analog output.

The range of usable values and the Setpoint units of measurement are displayed in the gray

box to the right of the Setpoint field.

The sensor type of the selected reference sensor determines the units of measurement, the

range of usable values, and the minimum differential between the Setpoint and End Point

values.

In this example, the SP value is 225 (psi) and the usable range is 90 to 500 psi.

7 EP (End Point) Enter the EP (End Point) value for the analog output.

The range of usable values and the end point units of measurement are displayed in the gray

box to the right of the End Point field.

The sensor type of the selected reference sensor determines the units of measurement, the

range of usable values, and the minimum differential between the End Point and Setpoint

values.

In this example, the EP value is 250 (psi) and the usable range is 90 to 500 psi.

8 OSP (Output at Setpoint) Enter the OSP (Output at Setpoint) value that you want the analog output signal strength to

be when the sensed condition is at SP (Setpoint).

The Output at Setpoint value is a percentage of the total output signal strength range. The

default OSP value is 0 and the range of usable values is 0 to 100.

In this example, the OSP value is 10 (10%).

9 OEP (Output at End Point) Enter the OEP (Output at End Point) value that you want the analog output signal strength to

be when the sensed condition is at EP (End Point).

The Output at End Point value is a percentage of the total output signal strength range. The

default OEP value is 100 and the range of usable values is 0 to 100.

In this example, the OEP value is 90 (90%).

10 I-C (Integration Constant) Enter the I-C (Integration Constant) value for the output. There are six integration constant

values (1 to 6). The default value (0) indicates that no integration constant is applied to the

analog output.

Johnson Controls recommends using the default value (0) when setting up your application

for the first time. Refer to the System 450 Series Modular Control Systems with Communications

Control Modules Technical Bulletin (LIT-12011826) for information on setting up and testing an

integration constant for your application.

In this example, the I-C value is the default value 0 and the integration feature is Off.

11 UP-R (Update Rate) Enter the UP-R (Update Rate) value at which the analog output signal strength is updated.

You can select an Update Rate value (time-interval in seconds) between 1 and 300.

In this example, the Update Rate value is the default value 1 (second).

12 bNd (Output Deadband) Enter the desired bNd (Output Deadband), within which the output signal strength remains

constant. The Output Deadband value is a percentage of the total usable sensor range. You

can set the Output Deadband value to be 0 to 50 of the total range.

In this example, Output Deadband is the default value 0.

13 Sensor Failure Mode of

Operation

Select from the drop-down menu how you want the relay output to respond when the

reference sensor or reference sensor wiring fails.

If you choose Fail Off, the analog output generates the selected OSP (Output Signal Strength

at Setpoint) value to the controlled device.

If you choose Fail On, the analog output generates the selected OEP (Output Signal Strength

at End Point) value to the controlled device.

In this example, Fail Off is selected. Therefore, if the reference sensor (Sn-1) or sensor wiring

fail, OUTA-2 provides the selected OSP (10%) to the controlled device until the sensor failure is

resolved.

System 450 Series Control Module with Ethernet Communications Installation Guide32

Loading...

Loading...