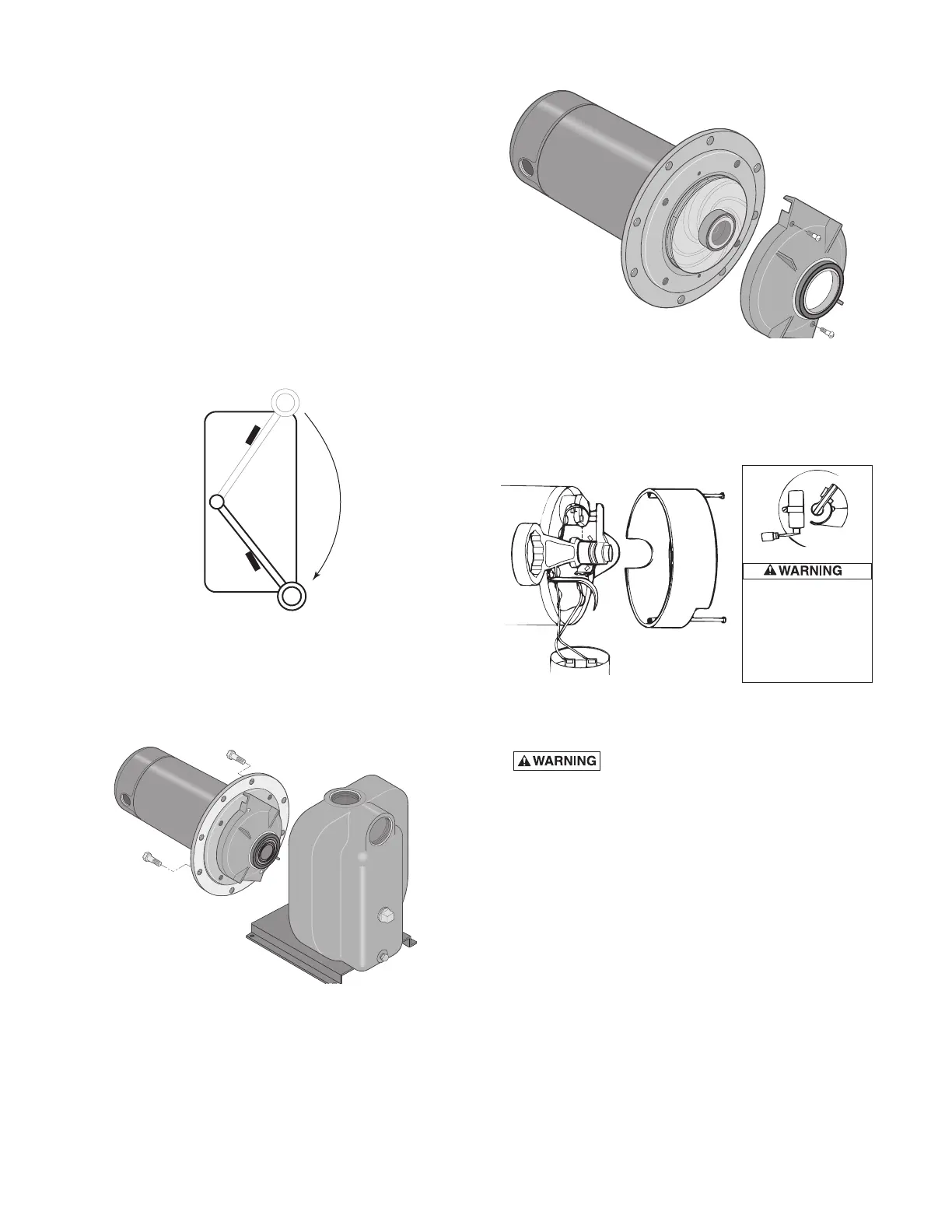

Maintenance

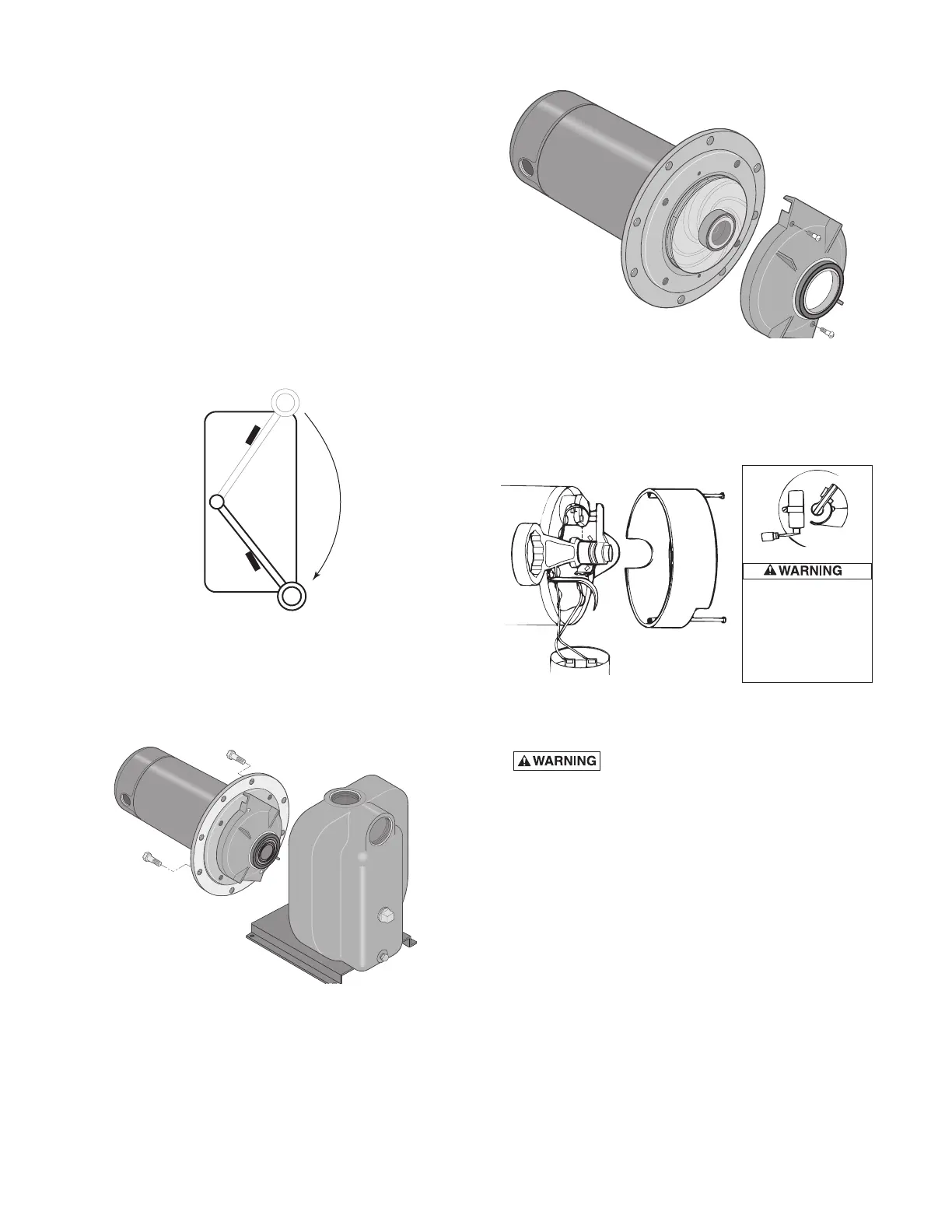

Pump and piping need not be disconnected to repair

or replace motor or seal (see Figure 14). If motor is

replaced, replace the shaft seal (Key No. 7, Page 12).

Keep one on hand for future use.

Be sure to prime pump before starting.

NOTICE: Check motor label for lubrication instructions.

The mechanical shaft seal in the pump is water

lubricated and self-adjusting.

NOTICE: Drain pump when disconnecting from service

or when it might freeze.

PUMP DISASSEMBLY

1. Disconnect power to motor.

NOTICE: Mark wires for correct assembly.

2. Remove capscrews holding seal plate to pump

body. Motor assembly and seal plate can now be

pulled away from pump body (Figure 14). CARE-

FULLY remove gasket.

CLEANING/REPLACING IMPELLER

NOTICE: First, follow instructions under “Pump Dis-

assembly”.

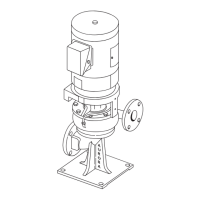

1. Remove screws fastening diffuser to seal plate;

re move diffuser (see Figure 15). Exposed impeller

can now be cleaned.

2. If impeller must be replaced, loosen two machine

screws and remove motor canopy (see Figure 16).

3.

Capacitor voltage may be

hazardous. To discharge capacitor, hold insulated

handle screwdriver BY THE HANDLE and short

capacitor terminals together (see Figure 16). Do not

touch metal screwdriver blade or capacitor terminals.

If in doubt, consult a qualified electrician.

4. Unscrew capacitor clamp and remove capacitor. Do

not disconnect capacitor wires to motor.

5. Slide 7/16” open end wrench in behind spring

loaded switch on motor end of shaft; hold motor

shaft with wrench on shaft flats and unscrew

impeller screw (if used) by turning clockwise (left

hand thread) when looking into eye of impeller.

6. Unscrew impeller while holding shaft by turning

counterclockwise while looking into eye of impeller.

7. To reinstall, reverse steps 1 through 6.

8. See directions under “Pump Reassembly,” Page 10.

8

ON

OFF

Figure 13 – Disconnect Power

Figure 14 – Slide Motor Back

Figure 15 – Remove Diffuser

Figure 16 – Hold Shaft

To avoid electrical

shock hazard, use

insulated-handle

screwdriver to short

capacitor terminals

as shown.

Loading...

Loading...