21

INTELLIFLO3™ VSF / INTELLIPRO3™ VSF Variable Speed and Flow Pump Installation and Maintenance Guide

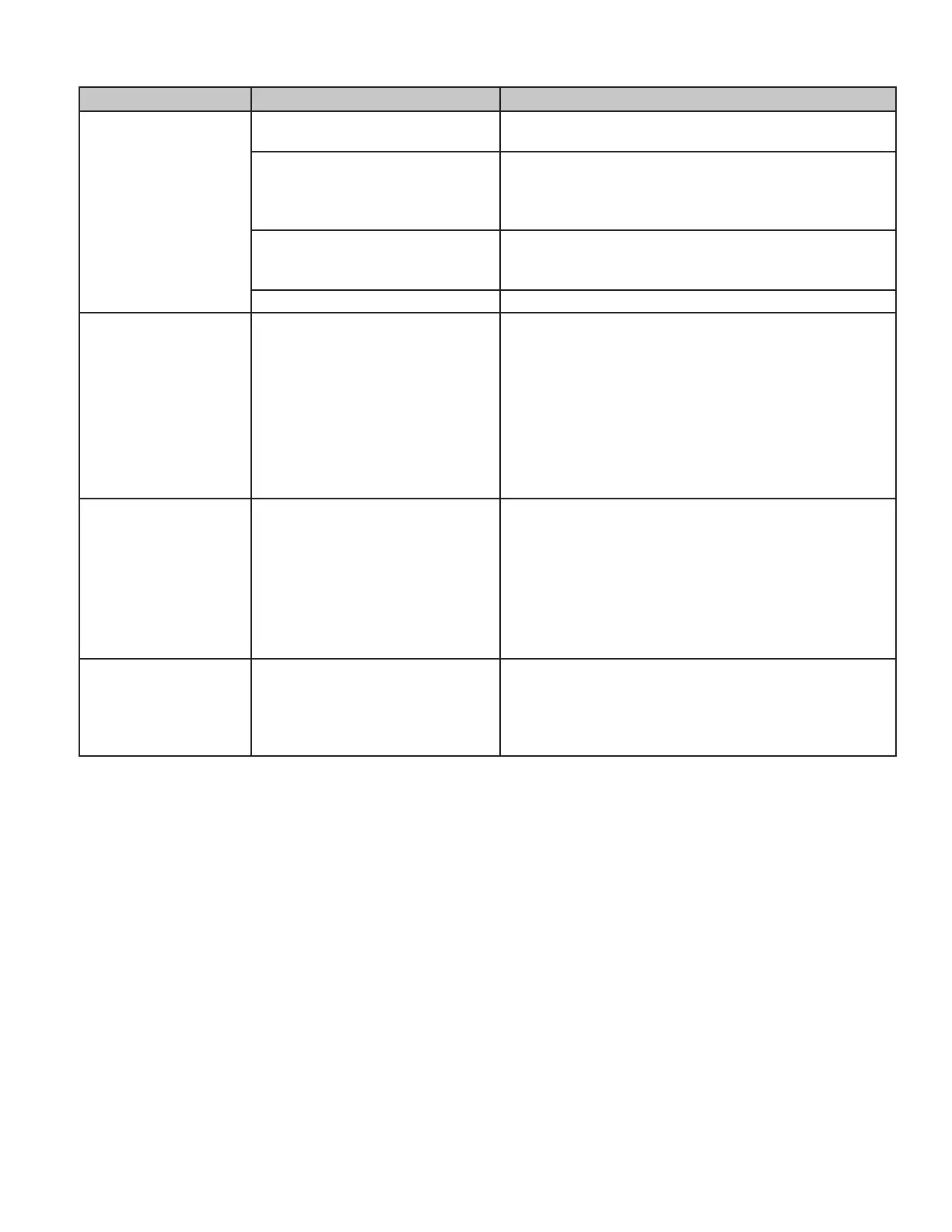

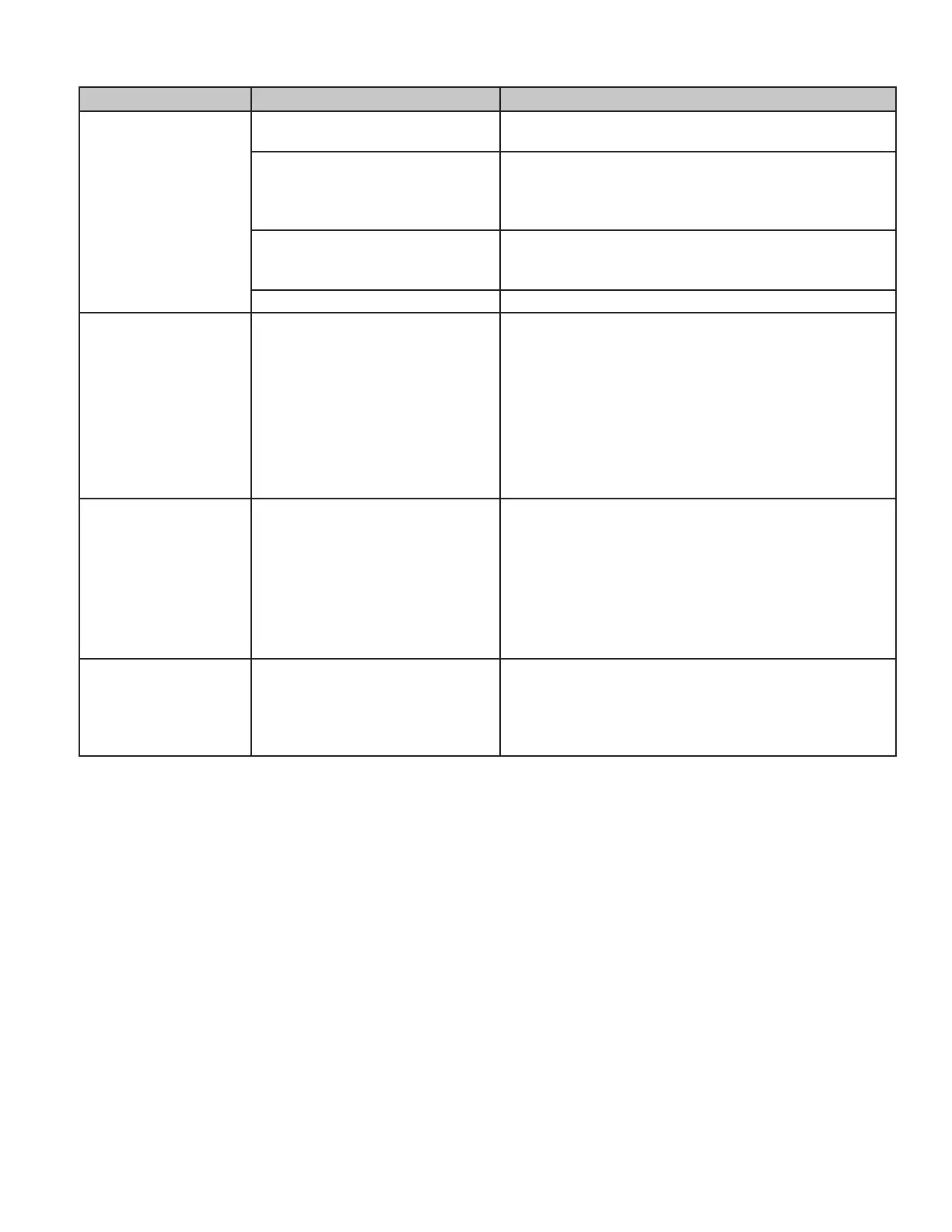

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Pump is Noisy or

Operating Loudly.

Debris in contact with cooling fan Ensure the fan guard is clean. Use compressed air to

remove any dirt, debris or blockages.

Clogged impeller Disassemble the pump and remove debris from the

impeller.

Refer to Disassembly on page 16 and Reassembly

on page 16 for instructions.

Too much debris in strainer basket

causing cavitation

Clean the pump strainer basket.

Refer to Pump Strainer Basket on page 13 for

instructions.

Motor speed too high Consider reducing the speed if possible.

Pump is Leaking

(from Strainer Pot -

Seal Plate Joint)

1. Ensure the seal plate O-ring is not pinched between

the seal plate and strainer pot.

2. Tighten the bolts joining the strainer pot and the

seal plate.

3. If leak persists, disassemble the pump.

Inspect all O-rings and seals for damage or debris

build-up. Replace or clean the seals if necessary.

Refer to Disassembly on page 16 and

Reassembly on page 16 for instructions.

Pump is Leaking

(from Strainer Pot Lid)

1. Ensure the strainer pot lid is installed correctly (lid

handles are perpendicular to the suction port) and

is compressing the strainer pot lid O-ring.

2. Refer to Pump Strainer Basket on page 13 and

remove the strainer pot lid.

Inspect the strainer pot lid O-ring for damage or

debris build-up. Replace or clean the O-ring if

necessary.

Pump is Leaking

(from Underneath

Motor)

Disassemble the pump and inspect the shaft seal.

The shaft seal is a wearable part and will need to be

replaced after prolonged operation.

Refer to Disassembly on page 16 and Reassembly

on page 16 for instructions.

Troubleshooting Chart (continued)

Loading...

Loading...