76

Troubleshooting

5

5-1. Troubleshooting guide

█

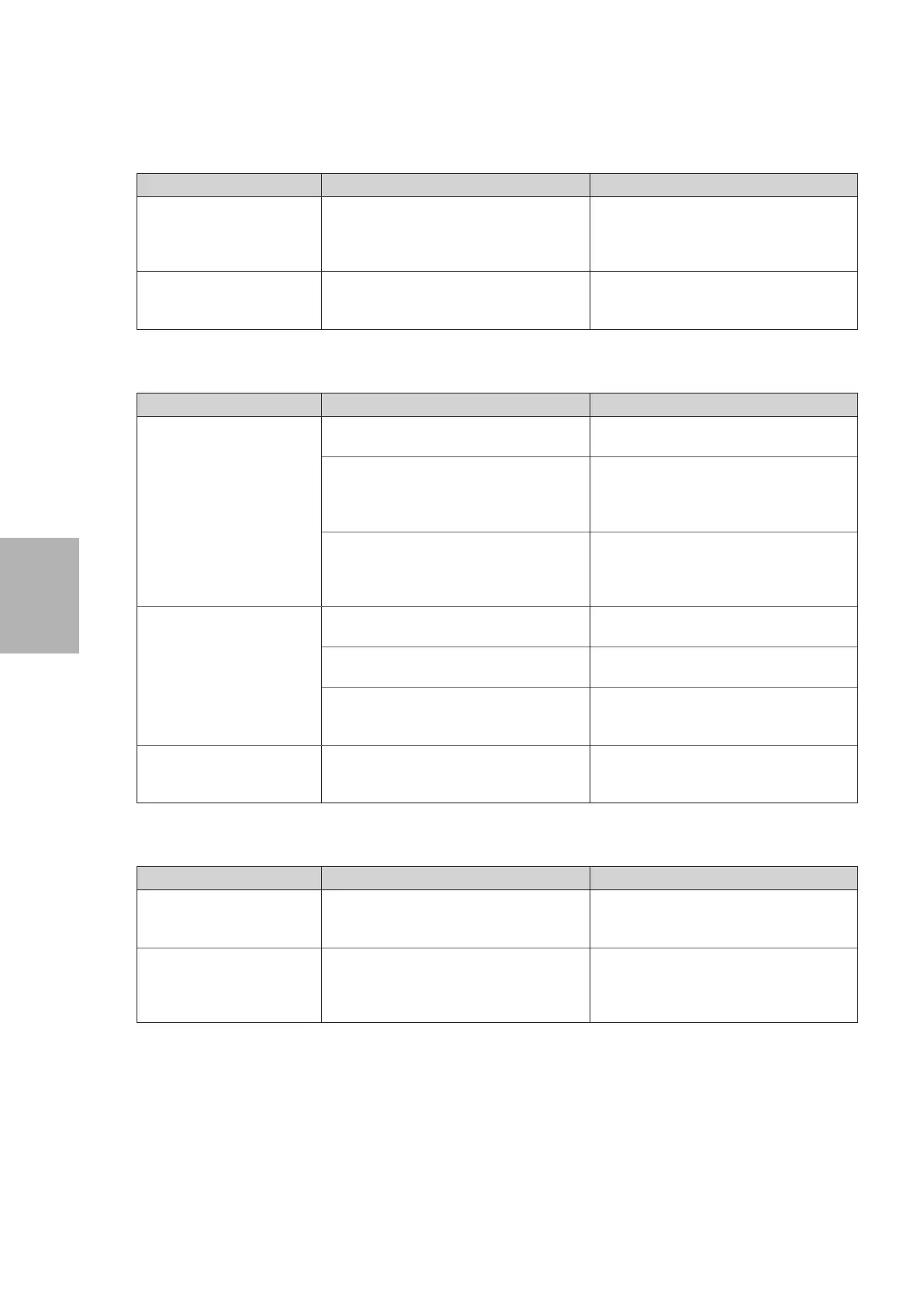

Connecting the video processor

Description of abnormality Possible cause Solution

The scope connector removes

from the video processor.

The scope connector is not all the way inserted

and fixed.

Check the scope connector and the video

processor for any inside attachment of foreign

materials; then push the scope connector until

it clicks and is fixed.

The scope connector cannot be

fully inserted.

The scope connector is inserted in wrong

direction (UP or DOWN).

Turn the scope connector's Connector UP

index (“

▲

“) upward and push the scope

connector into the video processor.

█

Image

Description of abnormality Possible cause Solution

The image is not displayed. The video processor, monitor, or other

equipment is not turned on.

Turn on the power of the instrument and all

other related devices.

The scope connector is not connected securely

to the video processor.

Push the scope connector into the video

processor receptacle until it clicks; then

ensure that the connector is securely attached

until it stops.

Foreign material has been attached to the

electrical contacts.

Wipe the electrical contacts with gauze

moistened with ethanol for disinfection; then

dry it sufficiently before connecting to the

video processor.

The image is too bright or too

dark.

The brightness level setting of the video

processor is not appropriate.

Set the video processor brightness to an

appropriate level.

The LED on the distal end of the endoscope

is turned off.

Turn on the lamp icon of the video processor.

Foreign material is attached to the light guide

at the distal end of the endoscope.

Gently clean the light guide with clean gauze

moistened with 70% – 90% medical grade

ethyl or isopropyl alcohol.

The image becomes foggy and /

or unclear.

Foreign material is attached to the objective

lens.

Gently clean the light guide with clean gauze

moistened with 70% – 90% medical grade

ethyl or isopropyl alcohol.

█

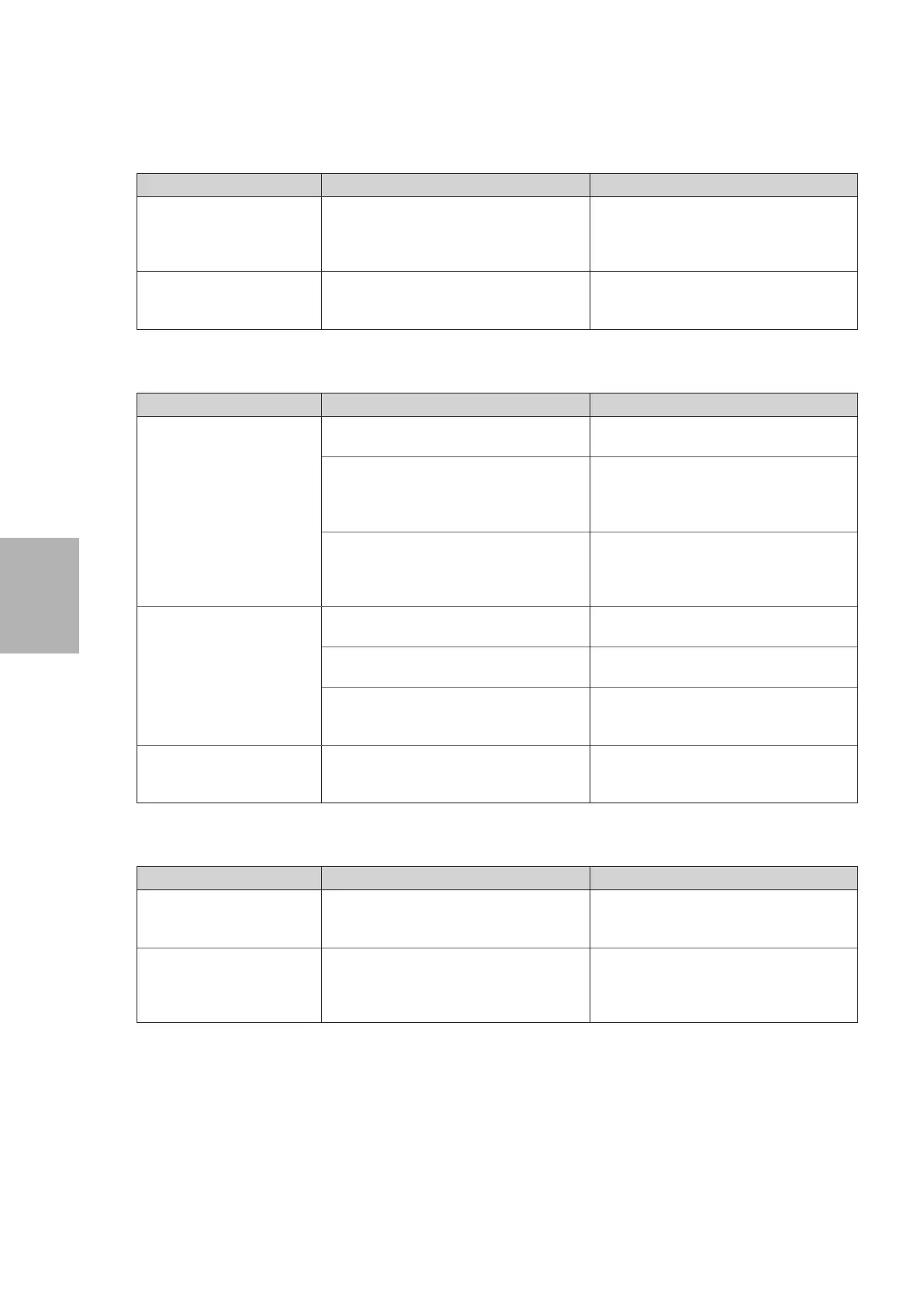

Angulation

Description of abnormality Possible cause Solution

Angulation control knobs feel

heavy to operate.

The bending section is fixed with the up /down

angulation lock lever or right / left angulation

lock knob.

Turn the up /down angulation lock lever or

right / left angulation lock knob in the “F

►

”

direction.

The bending section does not

return to straight condition

even when the angulation

control knobs are released.

The bending section is fixed with the up /down

angulation lock lever or right / left angulation

lock knob.

Turn the up /down angulation lock lever or

right / left angulation lock knob in the “F

►

”

direction.

Loading...

Loading...