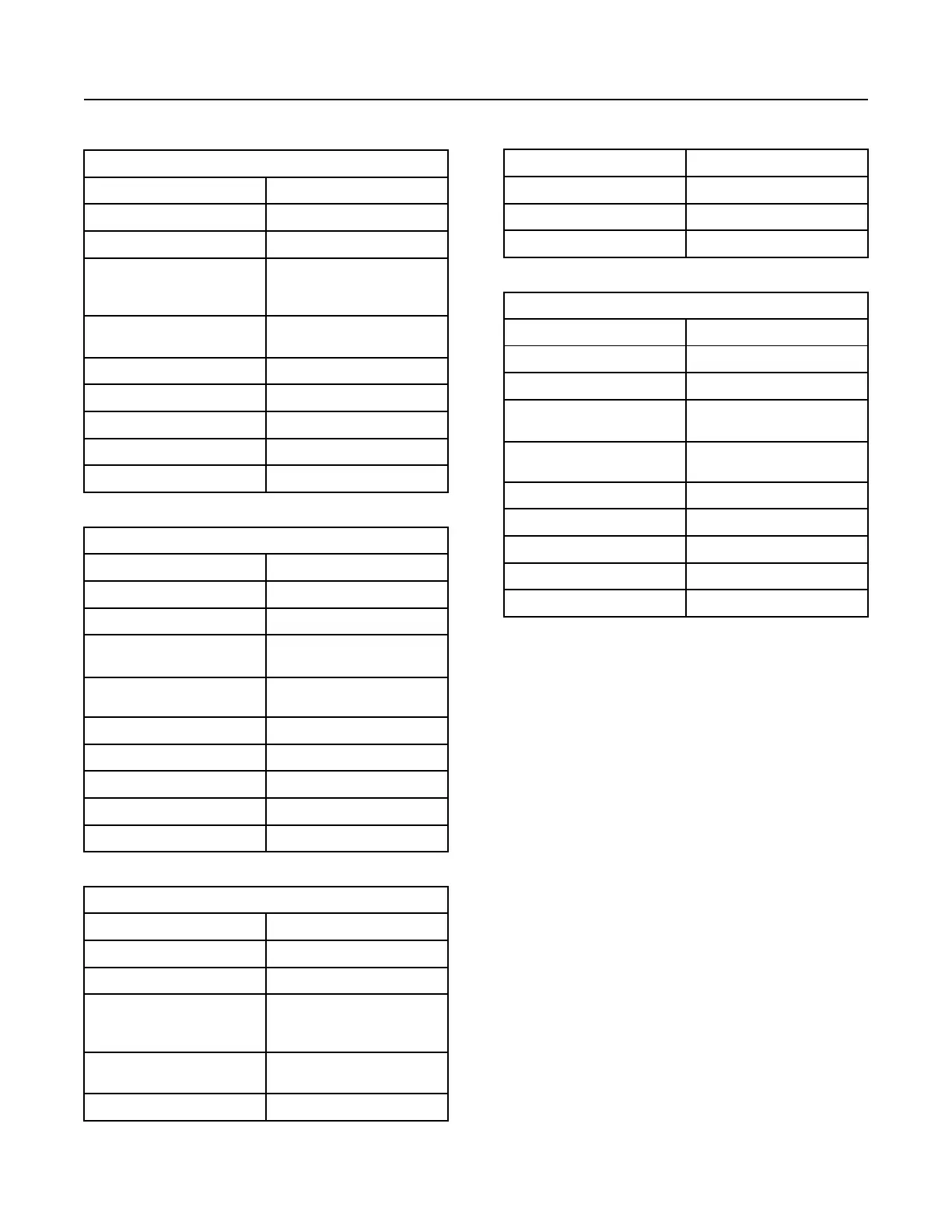

Table 1

1104 Industrial Engine Specifications

Number of Cylinders

4 In-Line

Bore 105 mm (4.134 inch)

Stroke 127 mm (5.0 inch)

Aspiration Turbocharged aftercooled

Turbocharged

Naturally aspirated

Compression Ratio NA 19.25:1 NA

T 18.23:1 T, TA

Displacement 4.4 L (268 in

3

)

Firing Order

1 3 4 2

Rotation (flywheel end)

Counterclockwise

Valve Lash Setting (Inlet) 0.20 mm (0.008 inch)

Valve Lash Setting (Exhaust) 0.45 mm (0.018 inch)

Table 2

1103 Industrial Engine Specifications

Number of Cylinders 3 In-Line

Bore 105 mm (4.134 inch)

Stroke 127 mm (5.0 inch)

Aspiration Turbocharged

Naturally aspirated

Compression Ratio NA 19.25:1

T 18.25:1

Displacement 3.3 L (201 in

3

)

Firing Order 1 2 3

Rotation (flywheel end) Counterclockwise

Valve Lash Setting (Inlet) 0.20 mm (0.008 inch)

Valve Lash Setting (Exhaust) 0.45 mm (0.018 inch)

Table 3

1104 Constance Speed Specifications

Number of Cylinders

4 In-Line

Bore 105 mm (4.134 inch)

Stroke 127 mm (5.0 inch)

Aspiration Turbocharged aftercooled

Turbocharged

Naturally aspirated

Compression Ratios NA 19.25:1

T 17.25:1, T 18.23:1, TA 18.23:1

Displacement 4.4 L (268 in

3

)

(continued)

(Table 3, contd)

Firing Order

1 3 4 2

Rotation (flywheel end)

Counterclockwise

Valve Lash Setting (Inlet) 0.20 mm (0.008 inch)

Valve Lash Setting (Exhaust) 0.45 mm (0.018 inch)

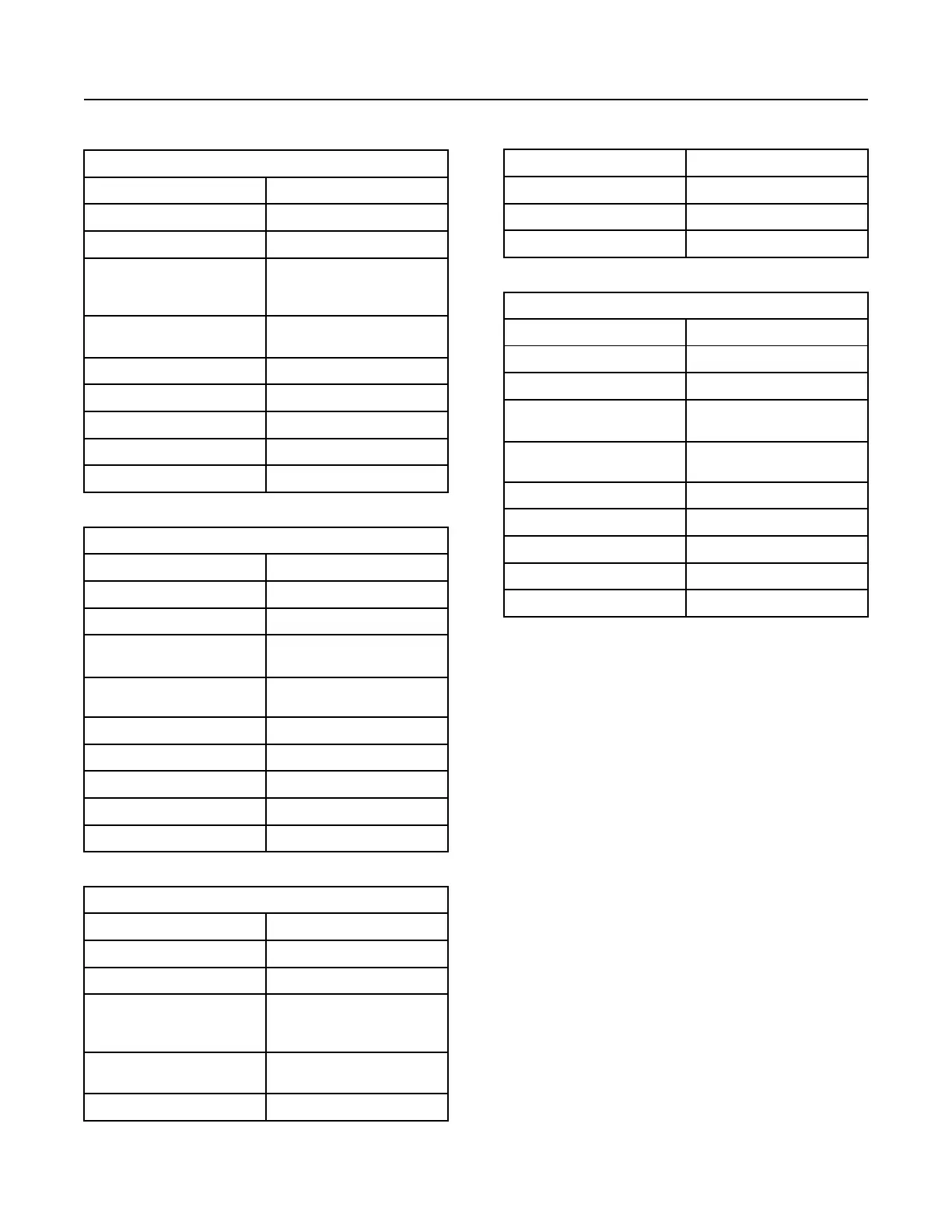

Table 4

1103 Constance Speed Specifications

Number of Cylinders 3 In-Line

Bore 105 mm (4.134 inch)

Stroke 127 mm (5.0 inch)

Aspiration Turbocharged

Naturally aspirated

Compression Ratio NA 19.25:1

T 17.25:1

Displacement 3.3 L (201 in

3

)

Firing Order 1 2 3

Rotation (flywheel end) Counterclockwise

Valve Lash Setting (Inlet) 0.20 mm (0.008 inch)

Valve Lash Setting (Exhaust) 0.45 mm (0.018 inch)

Engine Cooling and Lubrication

The cooling system consists of the following

components:

• Gear-driven centrifugal water pump

• Water temperature regulator which regulates the

engine coolant temperature

• Gear-driven oil pump (gear type)

• Oil cooler

The engine lubricating oil is supplied by a gear type

pump. The engine lubricating oil is cooled and the

engine lubricating oil is filtered. Bypass valves

provide unrestricted flow of lubrication oil to the

engine parts when oil viscosity is high. Bypass valves

can also provide unrestricted flow of lubrication oil to

the engine parts if the oil cooler should become

plugged or if the oil filter element should become

plugged.

Engine efficiency, efficiency of emission controls, and

engine performance depend on adherence to proper

operation and maintenance recommendations.

Engine performance and efficiency also depend on

the use of recommended fuels, lubrication oils, and

coolants. Refer to the Operation and Maintenance

Manual, “Maintenance Interval Schedule” for more

information on maintenance items.

SEBU7833 17

Model Views

Engine Description

Loading...

Loading...