52 SEBU8191-01

Maintenance Section

Cooling System Coolant Level - Check

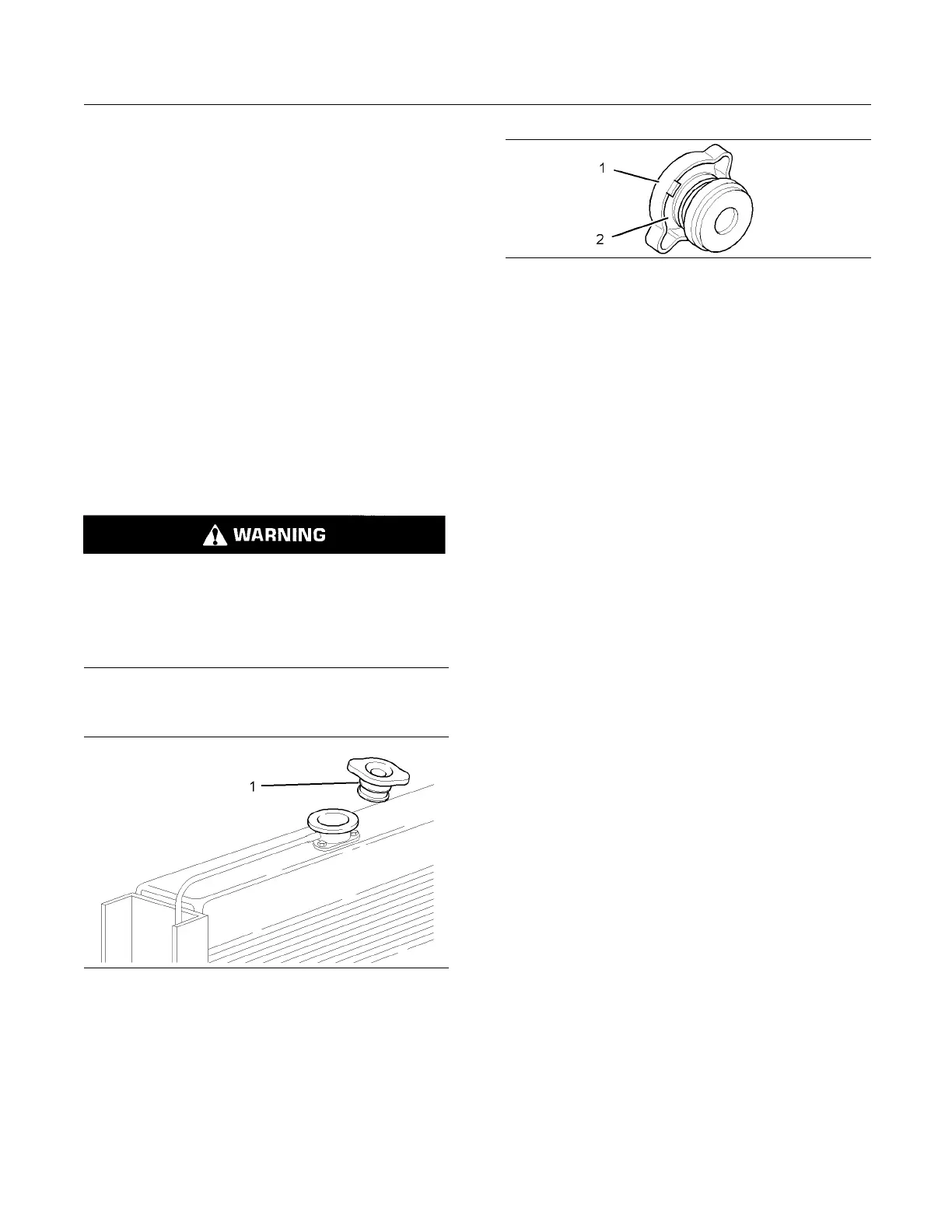

5. Clean the cooli

ng system filler cap (1) and inspect

the seal (2). If the seal is damaged, discard the

old filler cap and install a new filler cap. If the seal

is not damaged

,useasuitablepressurizingpump

in order to pressure test the filler cap. The correct

pressure is stamped on the face of the filler cap. If

the filler cap

does not retain the correct pressure,

replace the filler cap.

Install the

cooling system filler cap.

6. Start the engine and run the engine. Inspect the

cooling sys

tem for leaks. Ensure that the cooling

system operates at the correct temperature.

i02415245

Cooling System Coolant Level

- Check

Pressurized System: Hot coolant can cause seri-

ous burns. To open the cooling system filler cap,

stop the engine and wait until the cooling system

components are cool. Loosen the cooling system

pressure cap slowly in order to relieve the pres-

sure.

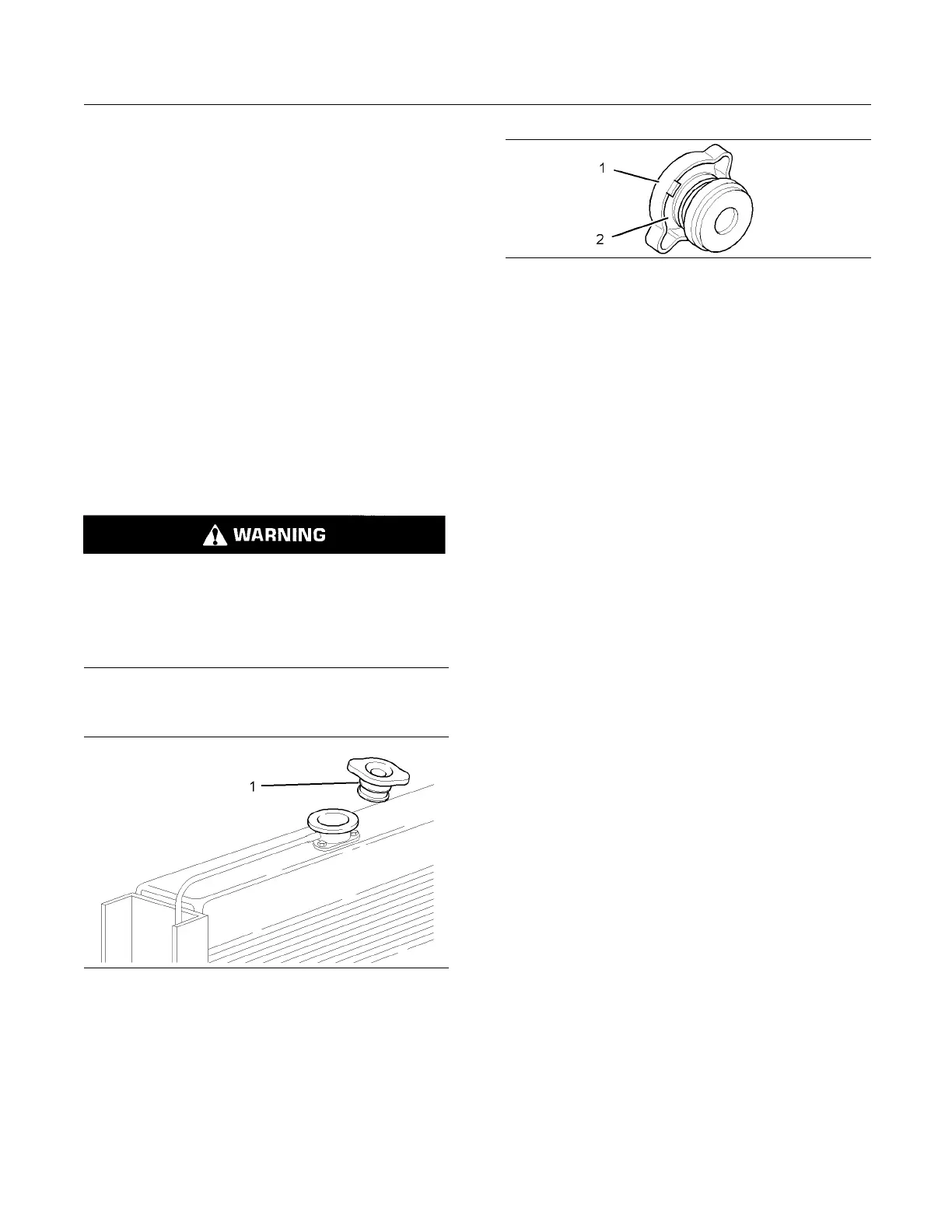

Check the coolant level when the engine is stopped

and cool.

g01211179

Il

lustration 46

1. Remove the cooling system filler cap (1) slowly in

or

der to relieve pressure.

2. Maintain the coolant level within 25 mm (1.0 inch)

o

f the bottom of the filler pipe.

g01239656

Illustration 47

3. Clean the cooling system filler cap (1) and inspect

the seal (2). If the seal is damaged, discard the

old filler cap and install a new filler cap. If the seal

is not damaged, use a suitable pressurizing pump

in order to pressure test the filler cap. The correct

pressure is stamped on the face of the filler cap. If

the filler cap does not retain the correct pressure,

replace the filler cap.

Install the cooling system filler cap.

4. Inspect the cooling system for leaks.

i02151646

Driven Equipmen t - Check

Refer to the OEM specifications for more information

on the following maintenance recommendations for

thedrivenequipment:

•

Inspection

•

Adjustment

•

Lubrication

•

Other maintenance recommendations

Perform any maintenance for the driven equipment

which is recommended by the OEM.

Loading...

Loading...