56 SEBU8191-01

Maintenance Section

Engine Oil Level - Check

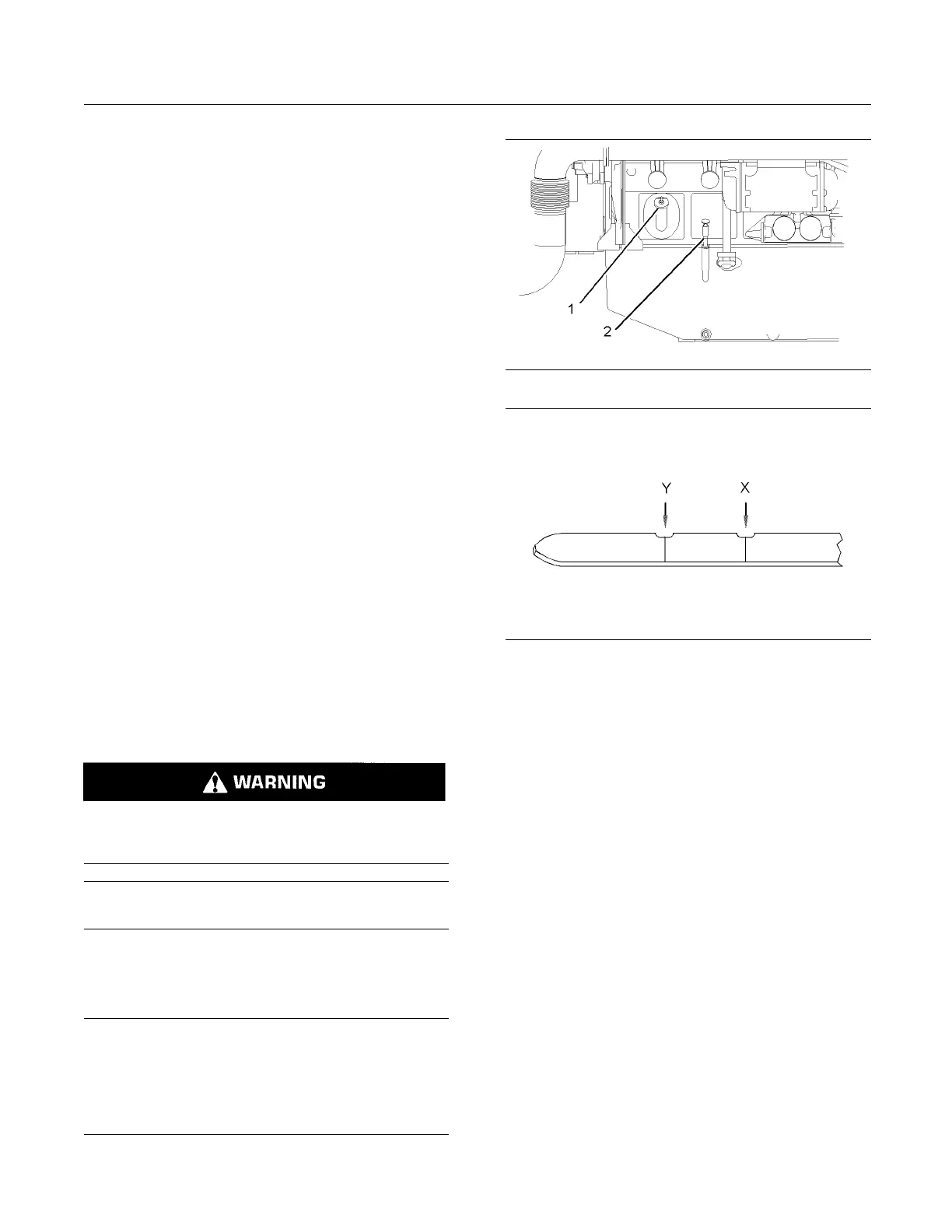

The changeover

valve (1) has three positions.

•

(A) The oil flow is to both oil filters.

•

(B) The oil flow is to the left-hand oil filter.

•

(C) The oil flo

w is to the right-hand oil filter.

1. Rotate the changeover valve to position B. By

usingasuit

able tool (2), remove the right-hand

oil filter.

Note: Oil flo

w direction (D and E ).

2. Ensure that the sealing face on the housing is

clean. Fil

l the new oil filter with clean engine oil.

Install the new oil filter. Rotate the changeover

valve to position A. Check for oil leaks.

3. Rotate the changeover valve to position C. By

using a suitable tool, remove the left-hand oil filter.

4. Ensure that the sealing face on the housing is

clean. Fill the new oil filter with clean engine oil.

Install t

he new oil filter. Apply hand pressure

only in order to install the oil filter. Rotate the

changeover valve to position A. Check for oil

leaks.

5. Clean any spillage of engine oil.

i02415261

Engine Oil L evel - Check

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

NOTICE

Per

form this maintenance with the engine stopped.

Note: After the engine has been switched OFF, wait

fo

r ten minutes in order to allow the engine oil to drain

to the oil pan before checking the oil level.

NOTICE

O

perating your engine when the oil level is above the

“Max” mark could cause your crankshaft to dip into

the oil. The air bubbles created from the crankshaft

d

ipping into the oil reduces the oil's lubricating char-

acteristics and could result in the loss of power.

g01236968

Illustration 54

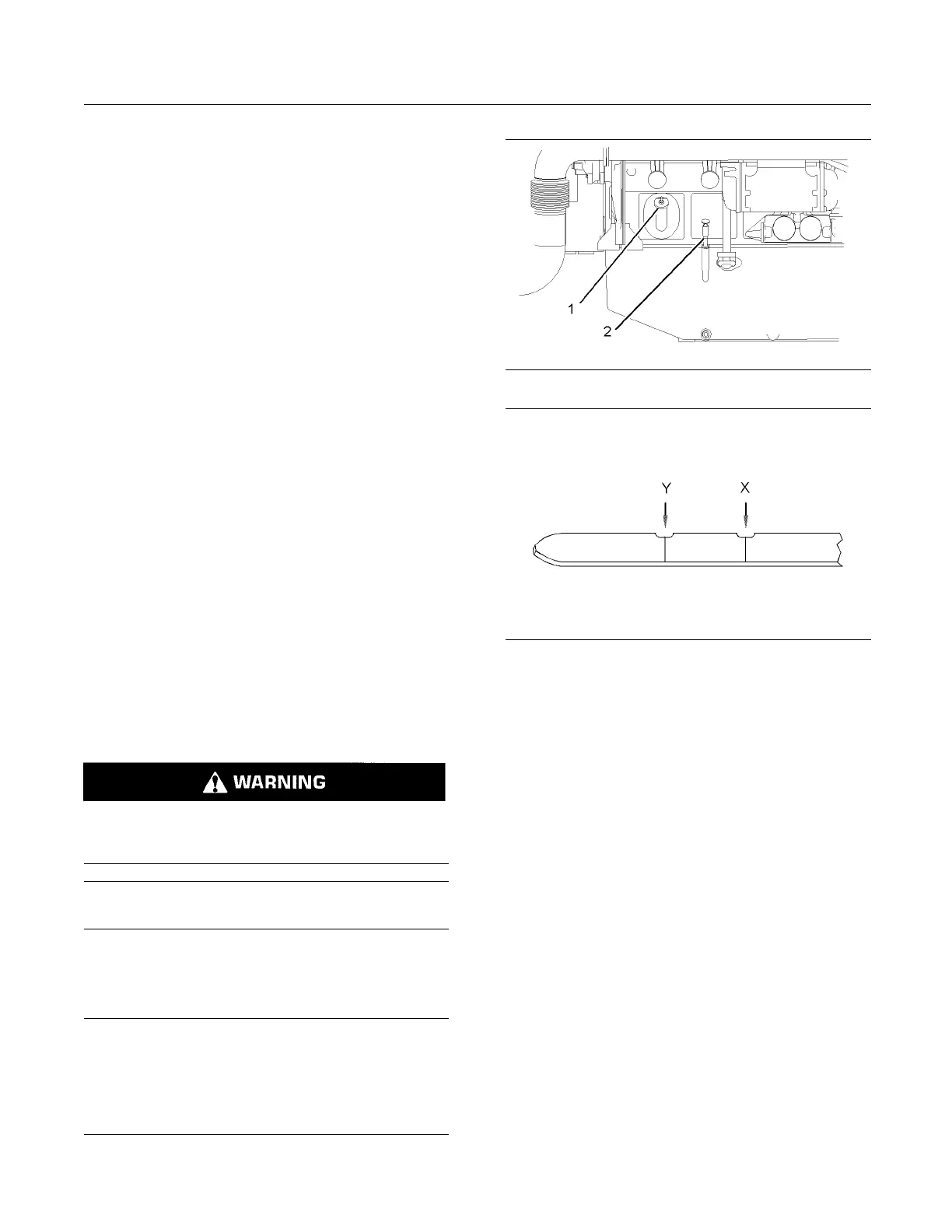

g01165836

Illustration 55

(Y) “Min” mark. (X) “Ma x” mark.

1. Maintain the oil level between the “Min” mark (Y)

and the “Max” mark (X) on the engine oil level

gauge (2). Do not fill the oil pan above the “Max”

mark (X).

2. If necessary, remove the oil filler cap (1) and add

oil. Clean the oil fi ller cap. Install the oil filler cap.

i02471700

Engine Oil Pump - Inspect

A failed engine oil pump may result in a seizure of

the crankshaft.

Remove the engine oil pump and disassemble the

engine oil pump. Refer to Operation Manual TSL4165

for more information. Inspect the components of

engine oil pump for wear and for damage. Refer to

Operation Manual TSL4165 for more information.

Replace any components that are worn or damaged.

Alternatively, replace the engine oil pump.

Loading...

Loading...