and

the

trimmer

snap

forword

toward

the

needle

thread.

Thereby

the

vertical

cam

N2 (Photo

24}

on the

movable

blade

of

the

needle

thread

trimmer

strikes

the

back

side

W

of

cam

guide

W, (Photo 23). As a

result,

the

trimmer

closes

and

the

thread

is

trapped

and

cut.

When re-storting the machine, the trimmer

bracket

Q is pulled

back

ond

pushed sufficiently

far

over

to the left by the

slanted

side

of

the .cam

guide W, so

that

the sprung lotch U will

again

be caught by

retainer

V.

Sprung latch U which yields

downwardly

should be held in position

about

Vj"

below

the

top

surface

of the

retainer

by

angle

X (Photo 23).

Retainer V must be

set

in such a

way

that

there will be a

clearance

of

.04"

between

sprung latch U

and

retainer

V when the trimmer is

retracted.

If

adjustment

is

required,

loosen

set

screw

Oi

and

move

the

retainer

V

as

may

be

required.

To avoid

damage

to the needle

thread

trimmer in

case

the knife cuts

too

early, guide screw Fj (Photo 24) of

bracket

Q is

provided

with a

taper

head

and

is

disposed

in such a

way

that

the slanted

edge

of the descending knife

bar

Mj will

force

the trimmer

bracket

Q bock so

as

to

keep

the knife from

striking

the

trimmer.

23.

The

Bobbin

Thread

Trimmer

As may be seen from photo 25, the bobbin thread trimmer consists of the

thread pull-off i and blades k and

I.

The thread pull-off i and blade k ore

both

carried

on

bracket

m.

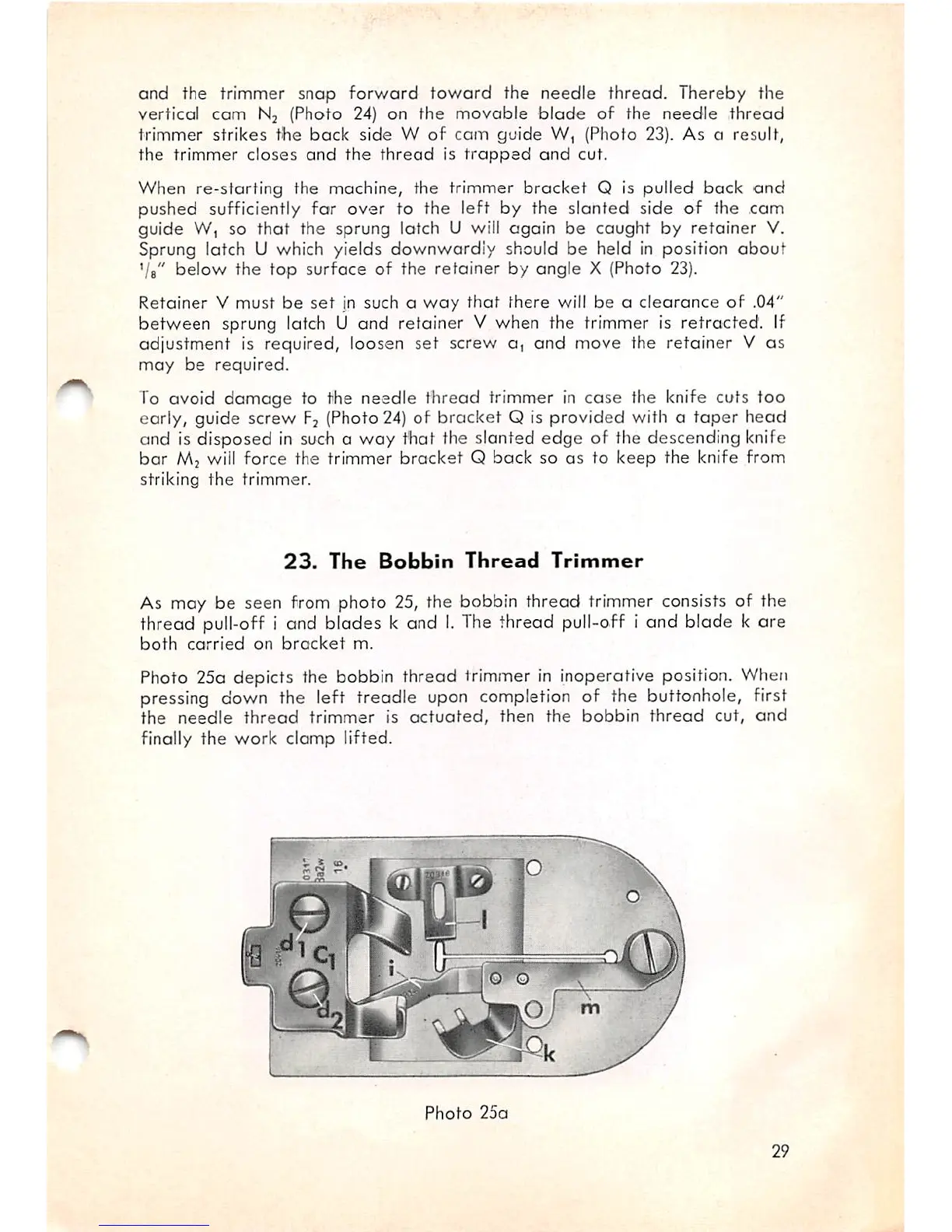

Photo 25a depicts the bobbin thread trimmer in inoperative position. When

pressing down the left treadle upon completion of the buttonhole, first

the

needle

thread

trimmer

is

actuated,

then

the

bobbin

thread

cut,

and

finally the work clamp lifted.

Photo

25a

29

Loading...

Loading...