S-DRIVE – APPENDIX - A PG DRIVES TECHNOLOGY

SK76745/10

3.3 Parallel speed-limiting potentiometer

Initial track resistance: 100 kilohm ± 20 %

4 Programmable settings

4.1 Throttle deadband

Wigwag/Unipolar throttle: setting not less than 15 %

Single-ended throttle: setting not less than 10 %

4.2 ISO-test resistor

Since ISO-test resistors will not be used, the ISO-test resistor setting should be OFF.

5 Installation instructions

5.1 Leakage path management

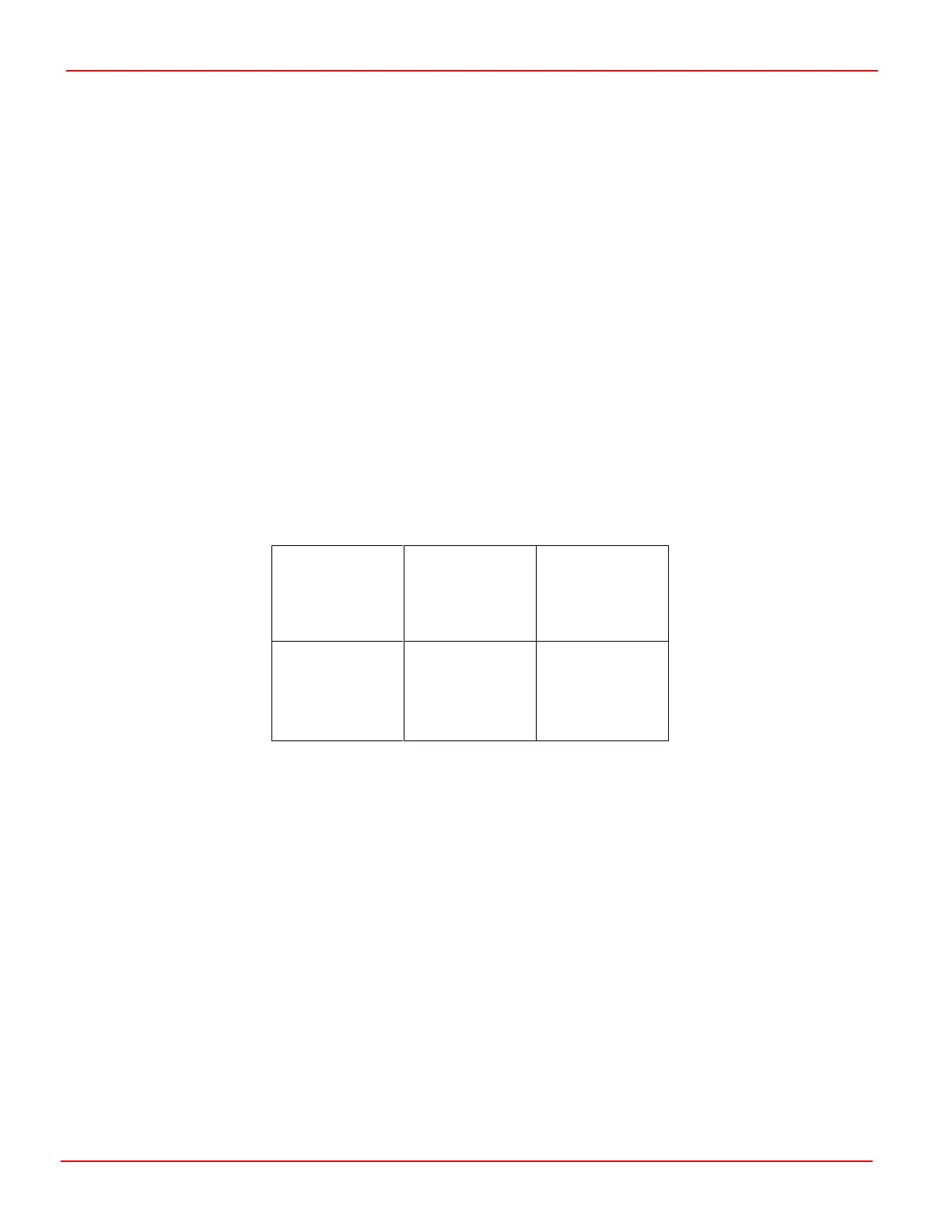

The evaluation of the S-Drive is based on the premise that the only reasonably foreseeable leakage that can occur is between a

defined set of conductors. Consider the pins at the end of the S-Drive tiller interface connector, shown in the following diagram.

pin 2

throttle high

reference

pin 8

throttle low

reference

pin 9

speed-limiting

potentiometer

Leakage paths have been evaluated for all analogue signals in the set to adjacent pins (horizontally, vertically and diagonally).

The voltage on the audible alarm and status indicator connections can cover the entire battery voltage range.

The most important signal in this set is the throttle wiper, pin 1. It can meet the ISO leakage requirement for the adjacent pins but

it cannot meet the requirement for leakage to any signal with a wider voltage range while keeping a realistic value for the

deadband. Therefore, to ensure conformity, it is essential that no reasonably-foreseeable leakage due to contamination by

liquids can occur between the throttle wiper and any signals other than those on pins 2, 8 and 9.

There are three main methods to prevent this leakage: physical barriers, creepage distances, and guard conductors. These will

be considered in the following sections relating to different parts of the throttle circuitry.

5.2 Printed circuit boards

Where the throttle circuitry is connected via a printed circuit board, the following techniques are recommended.

1) All parts of tracks that are not necessary to expose should be coated in solder resist.

2) All tracks connected to the throttle potentiometer should be conformally coated. This includes the soldered

terminals of connectors.

3) The throttle wiper, throttle high reference, throttle low reference and speed limiting potentiometer signal (if used)

should be segregated from other conductors on the printed circuit board by large creepage distances. The

larger this distance can be made, the better the immunity to leakage will be. At least 3 mm is recommended.

Loading...

Loading...