23 | P a g e

The total number of changed parameters, and the current index of changed parameters,

will be displayed at the top of the screen. If there are no changed parameters, then “No

Changed Parameters” will be shown.

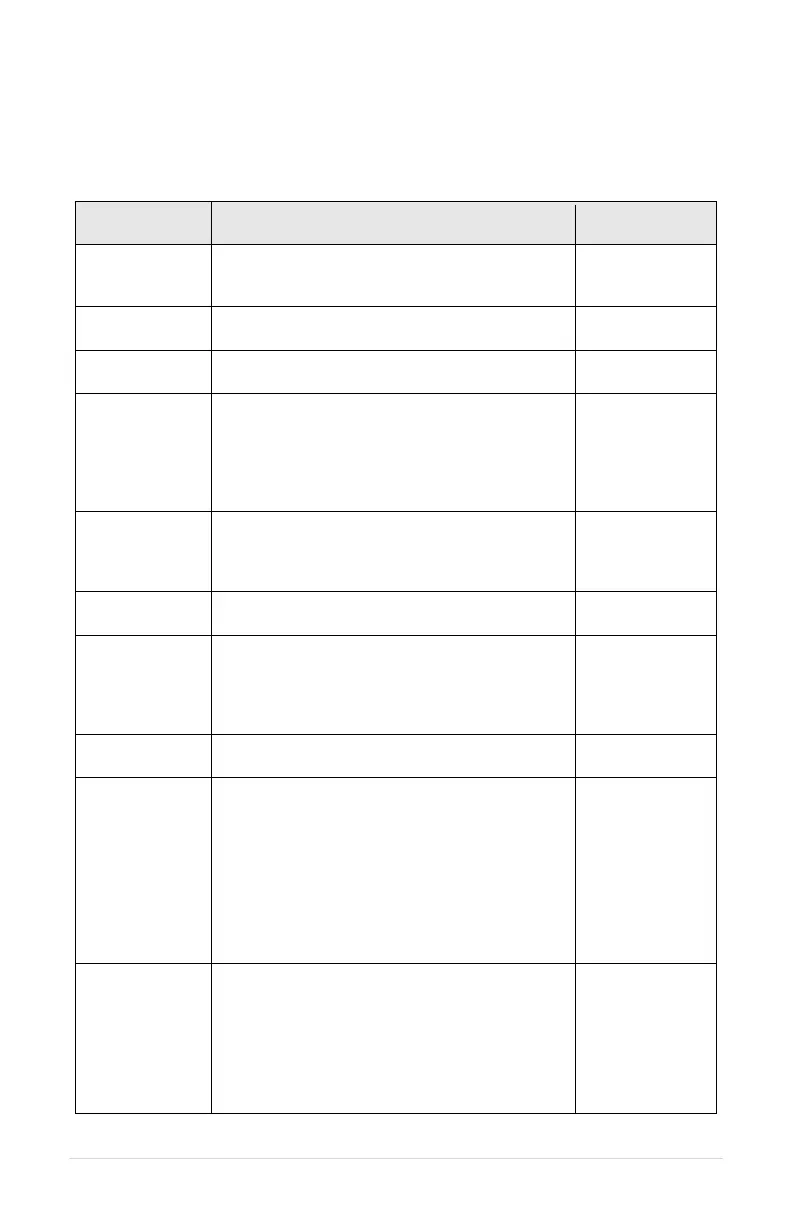

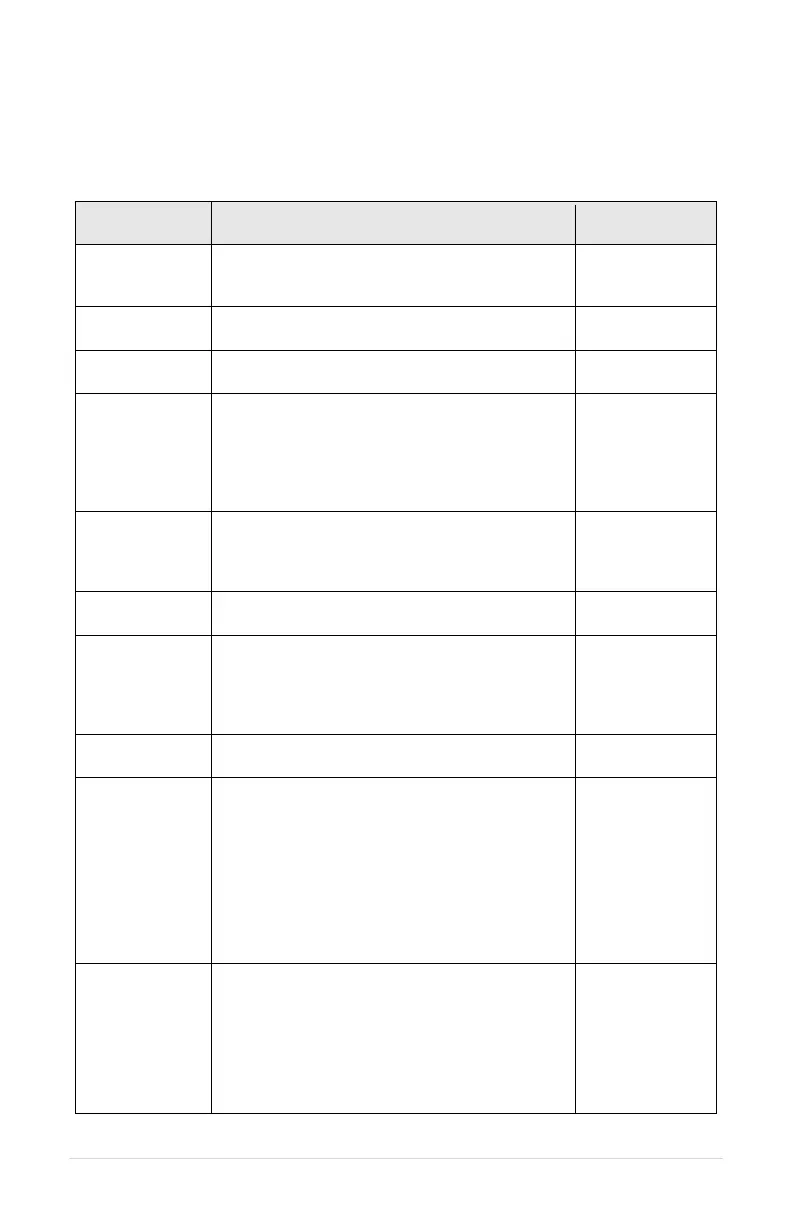

Table 12 – Operating Parameters

Maximum frequency allowed, or target frequency

at start-up ramp. This parameter value cannot be

set lower than MINIMUM FREQ.

Minimum output frequency allowed except during

startup ramp.

Used to select 2-wire or 3-wire motor.

Select the motor manufacturer to optimize

performance. When “Franklin” is chosen, the

drive will be compatible with motors containing

BIAC switches.

Default: Franklin

Pentek

Grundfoss

Other (Prompted

to select MOTOR

PHASE ANGLE)

For 3-wire drives only when “OTHER” is selected

for MOTOR MANUFACTURER. Use this to

select PHASE ANGLE based on motor specs.

Adjust PHASE ANGLE to reach desired torque.

Based on MOTOR

MANUFACTURER

/120/180

Time in seconds of linear ramp from MIN

FREQUENCY to MAX FREQUENCY.

Time in seconds from MAX FREQUENCY to MIN

FREQUENCY. Ramp time is linear. Factory

default setting enables the COAST TO STOP

parameter which disables the SHUTDOWN

RAMP parameter.

Setting for motor overload protection, Trip Class

10 curve.

DRY WELL

CURRENT

(Undercurrent

Setpoint)

Drive faults when output current goes below the

set value (dry well protection).

To use this function for dry well protection, make

certain the parameter DRY WELL KW is set at

zero.

Note: Fluctuating voltage can change motor

currents without any change in power

consumption. It may be more accurate to use the

parameter DRY WELL KW for drywell protection.

DRY WELL KW

(Underpower

Setpoint)

Drive faults when output measured in KW goes

below the set value (dry well protection).

Generally more accurate than DRY WELL

CURRENT.

To use this function for dry well protection, make

certain the parameter DRY WELL CURRENT is

set at zero.

Loading...

Loading...