35 | P a g e

Fine Tuning With PI Control

When operating in constant pressure mode, if the parameter PROPORTIONAL GAIN is set

to a value less than 1, the keypad displays SIMPLE MODE and the controller uses an

algorithm that is not PI control. Simple Mode requires less fine tuning than PI control, but in

some applications may not provide the control and stability desired. The stability of the

constant pressure system (i.e., its tendency not to exhibit pressure oscillations) is

determined by parameters set on the keypad, the flow rate of the pump, and the volume of

the pressure tank. Stability of a system with a large maximum flow rate and a small

pressure tank will be more difficult to control and may require de-tuning the system to

accept larger variations in the system pressure and longer response times. Analog constant

pressure systems with PI (proportional integral) control provide more options to fine tune

pressure control than Simple Mode. Systems that are not adequately controlled with the

Simple Mode may require fine tuning by switching to PI control. Increasing the value of

PROPORTIONAL GAIN to any value greater than SIMPLE MODE will initiate PI control.

Pressure control is achieved by adjusting the values of PROPORTIONAL GAIN and

INTEGRAL GAIN. Larger values for PROPORTIONAL GAIN and INTEGRAL GAIN give

smaller error in the pressure, but also make the system more susceptible to oscillation. The

following pages of this Section will provide more information on tuning PI control.

Emergency Over-Pressure Limit Switch

Constant pressure systems have the option of connecting an emergency over-pressure

limit switch to the AUX2 terminals in case the main pressure control system fails. The

emergency over-pressure set-point should be at least 10 psi higher than the system control

pressure to prevent nuisance tripping.

CAUTION: By default, AUX1 is programmed such that OPEN=STOP, CLOSED=RUN

and AUX2 is programmed such that OPEN=RUN, CLOSED=STOP. When SYSTEM

CONFIG = 2 (Analog CP), AUX1 and AUX2 are programmed such that OPEN=RUN,

CLOSED=STOP. See parameters AUX1 SELECT and AUX2 SELECT to change this

setting.

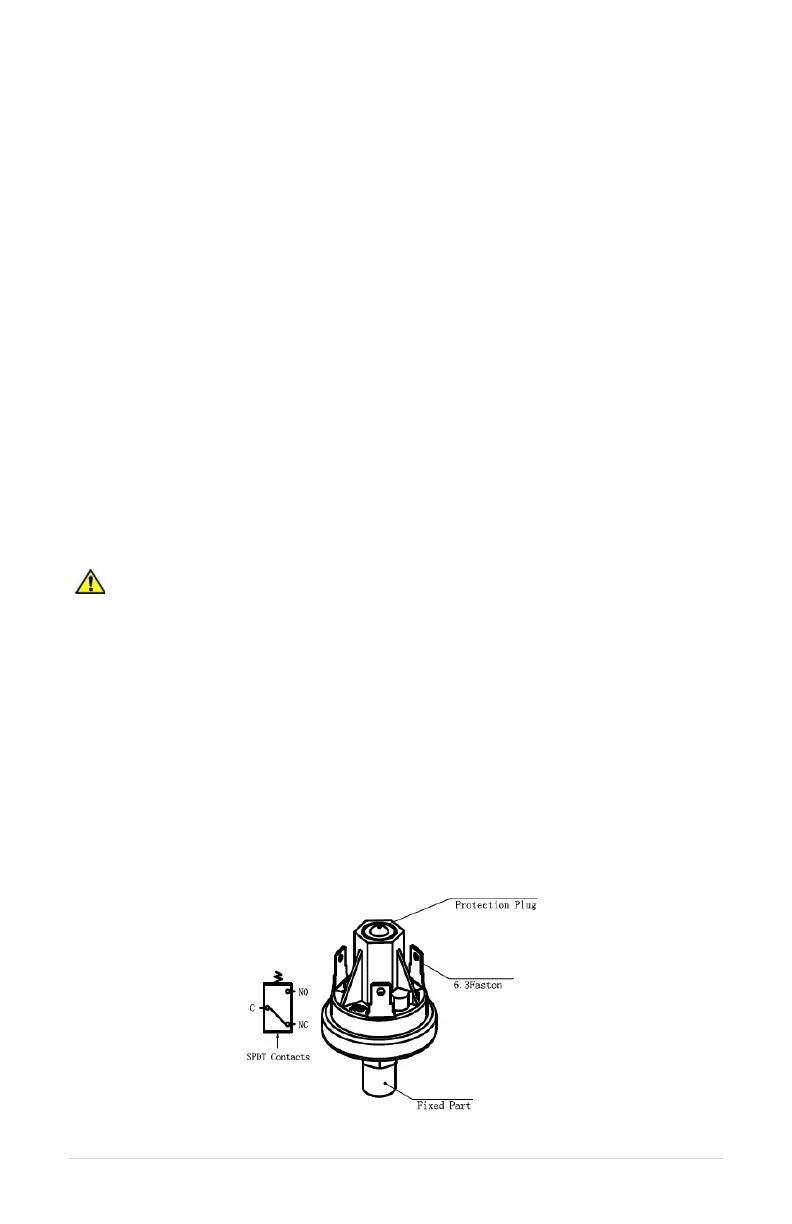

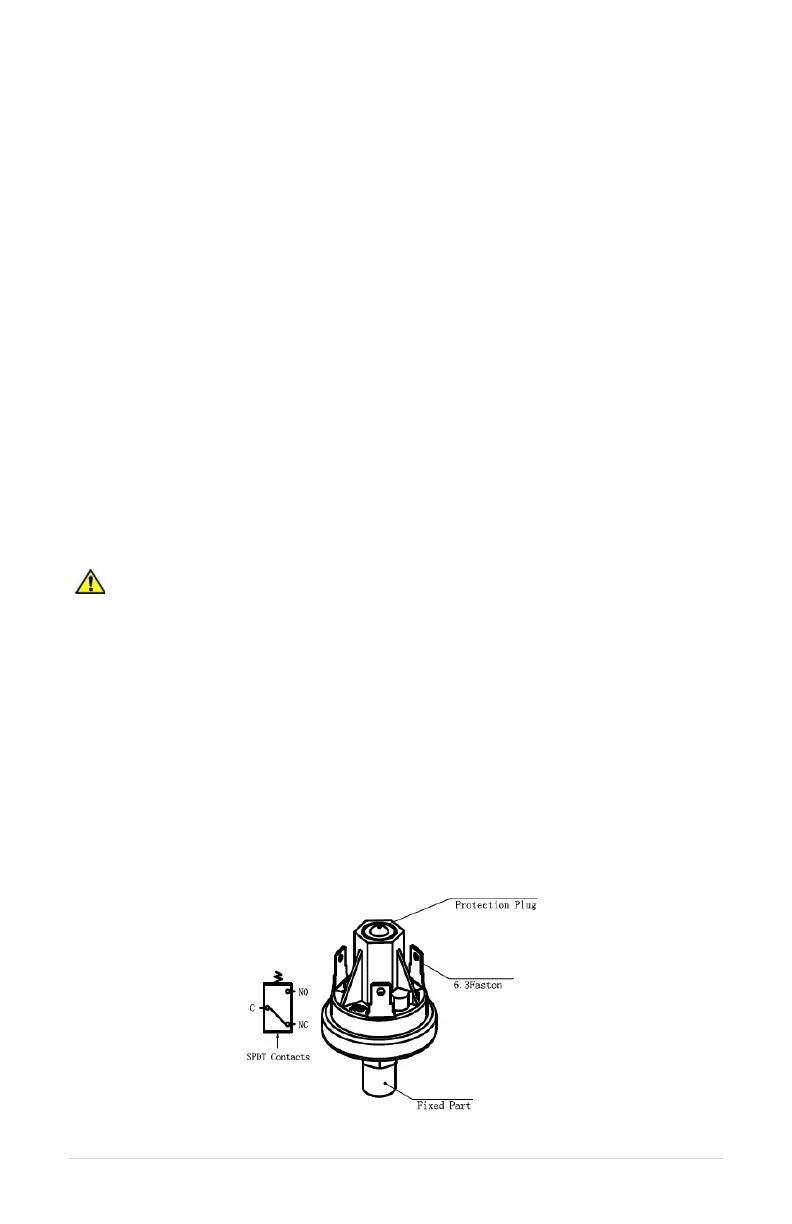

7.2 Digital Pressure Switch

Each Essential Drive comes standard with a pressure switch set to 60 psi. The pressure set

point can be adjusted by removing the protection plug and using a 5mm Allen wrench to

turn the screw. See Figure 18 to identify the protection plug. Turning the screw clockwise

will increase the pressure set point and turning the screw counterclockwise will decrease

the pressure set point. The operating pressure range is 25 psi – 150 psi. Run the pump in

AUTO mode, and observe the pressure gauge, turning the Allen screw to adjust the

pressure set point.

Figure 18 – Pressure Switch

Loading...

Loading...