34 | P a g e

DRAWDOWN PSI and BOOST AMOUNT

The primary method of preventing short cycling is to allow a differential between the

pressure at which the pump turns off to enter sleep mode and the pressure at which it

restarts. Two parameters, DRAWDOWN PSI and BOOST AMOUNT, control this

differential. BOOST AMOUNT specifies the increase in pressure above psi SETPOINT just

before the pump shuts down to enter sleep mode, while DRAWDOWN PSI specifies the

pressure drop below psi SETPOINT at which the pump restarts. For example, assume psi

SETPOINT = 50, BOOST AMOUNT = 5, and DRAWDOWN PSI = 5. When the pump is

ready to enter sleep mode, the pump will boost to 55 psi, then restart when the pressure

falls to 45 psi. These two parameters can be used together or independently to create a

dead band in pressure control.

Both OVERPRESSURE PSI and SHUTOFF FREQUENCY cause the drive to enter sleep

mode. OVERPRESSURE psi is additional system protection. It is a value that is added to

the psi SETPOINT. The default value for OVERPRESSURE psi is 20. For example, if the

psi SETPOINT is 50psi, the drive will stop the motor if pressure reaches 70psi.

The parameter SHUTOFF FREQUENCY is used to put the drive in sleep mode when

pressure is controlled and flow is low. Shut off frequency is a value that is added to MIN

FREQUENCY. For example, if minimum frequency is 30 Hz and shut off frequency is 12,

the drive will enter sleep mode at 42 Hz. When a value of zero is entered for the parameter

SHUTOFF FREQUENCY, sleep mode is disabled.

CAUTION: When sleep mode is disabled in low flow conditions, the drive will slow

down to minimum frequency and continue to run. Inadequate water flow in this condition

may overheat and damage the pump.

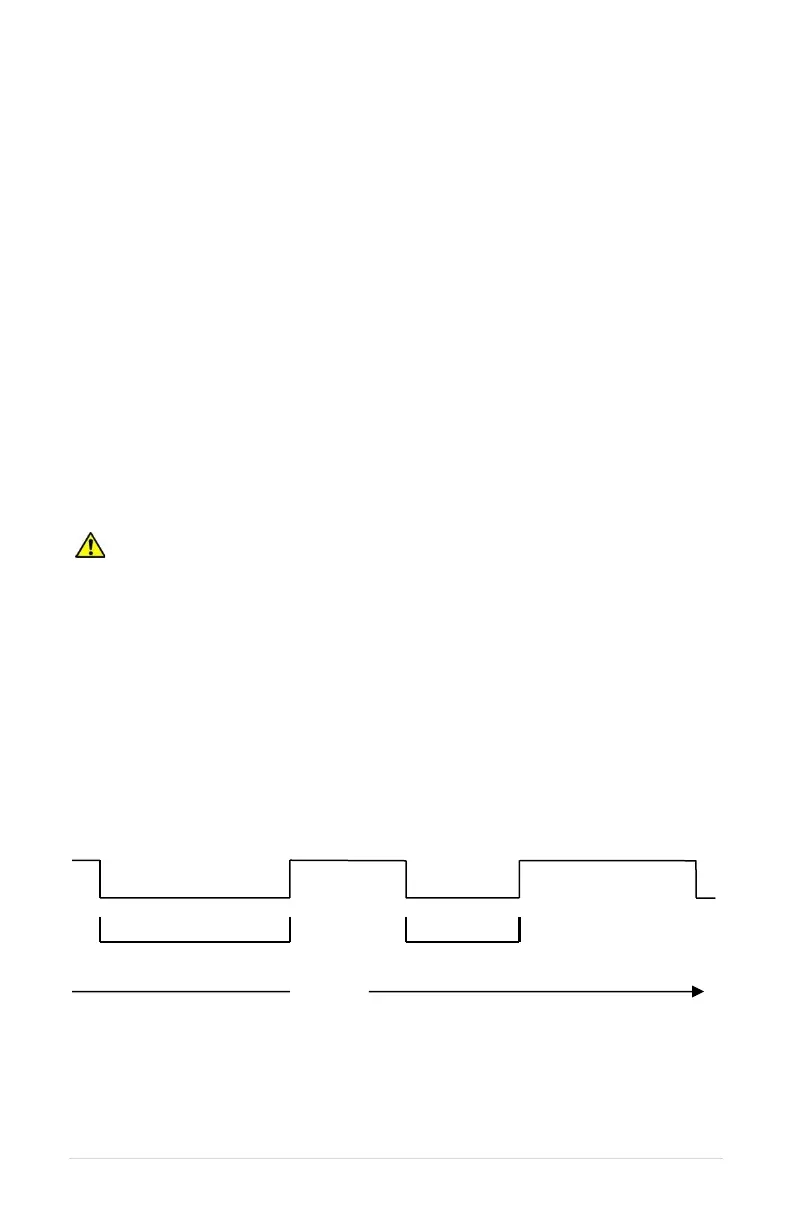

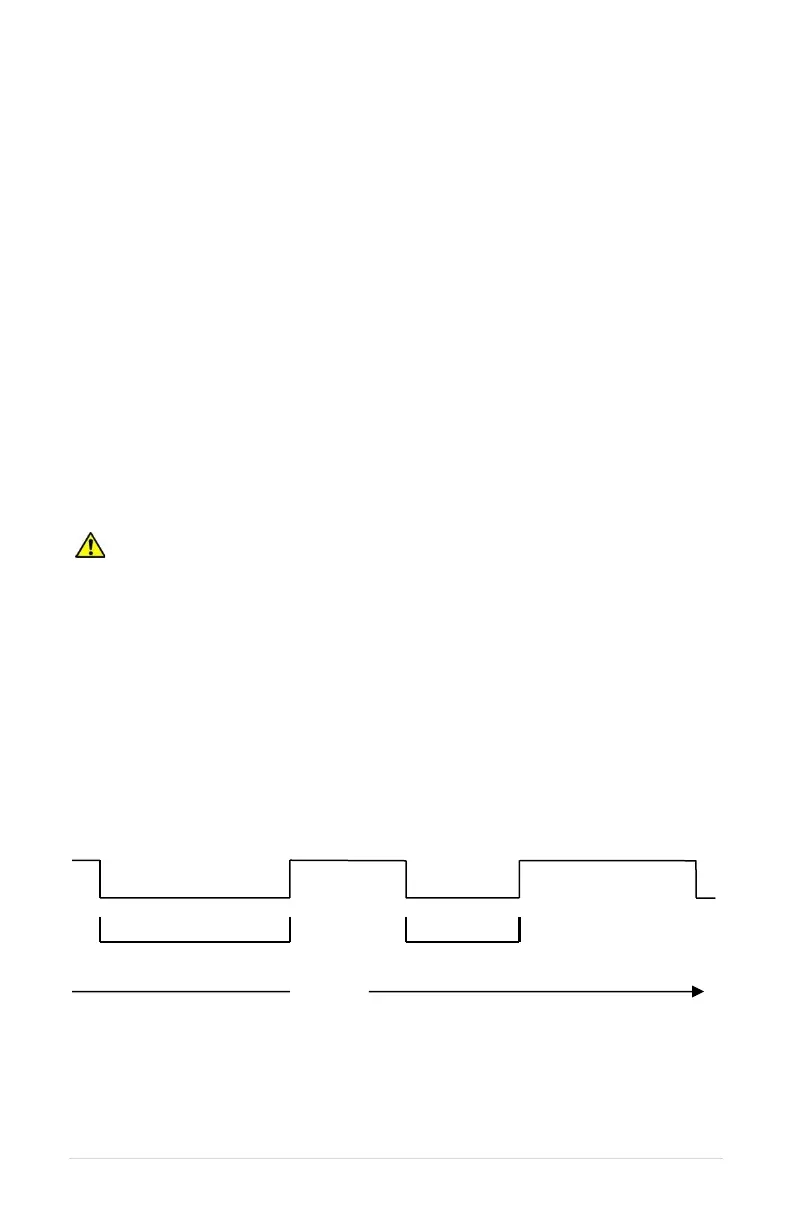

ON/OFF Cycle Timers

The drive records the length of time the motor remained in the OFF cycle and compares

that time to the parameter, TOFF. If the motor-off time during the last OFF cycle was

greater than the value of TOFF, then the minimum motor-on time will be equal to T1ON. If

the motor-off time was less than TOFF, the minimum motor-on time will be equal to T2ON.

In other words, the time of the last OFF cycle determines whether the next ON cycle should

be relatively long or relatively short. The graphic in Figure 17 demonstrates how the

system adjusts the motor-on time in response to motor-off time.

Figure 17 – Motor On and Off Times

Loading...

Loading...