NLGI 2 specifications; ISO-LXBIB2

SEALING RINGS - FITTING

(Manual operation that does not require the use of the press).

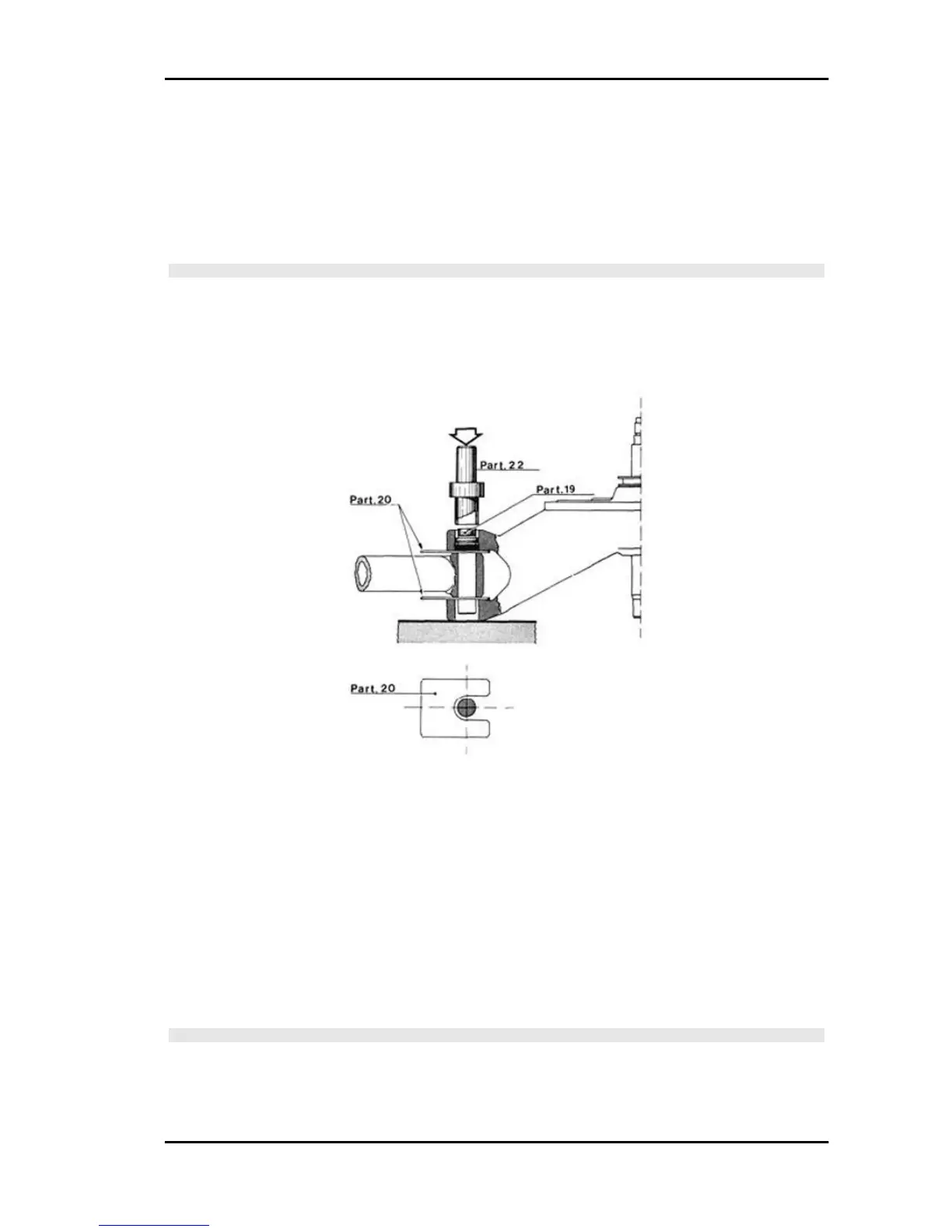

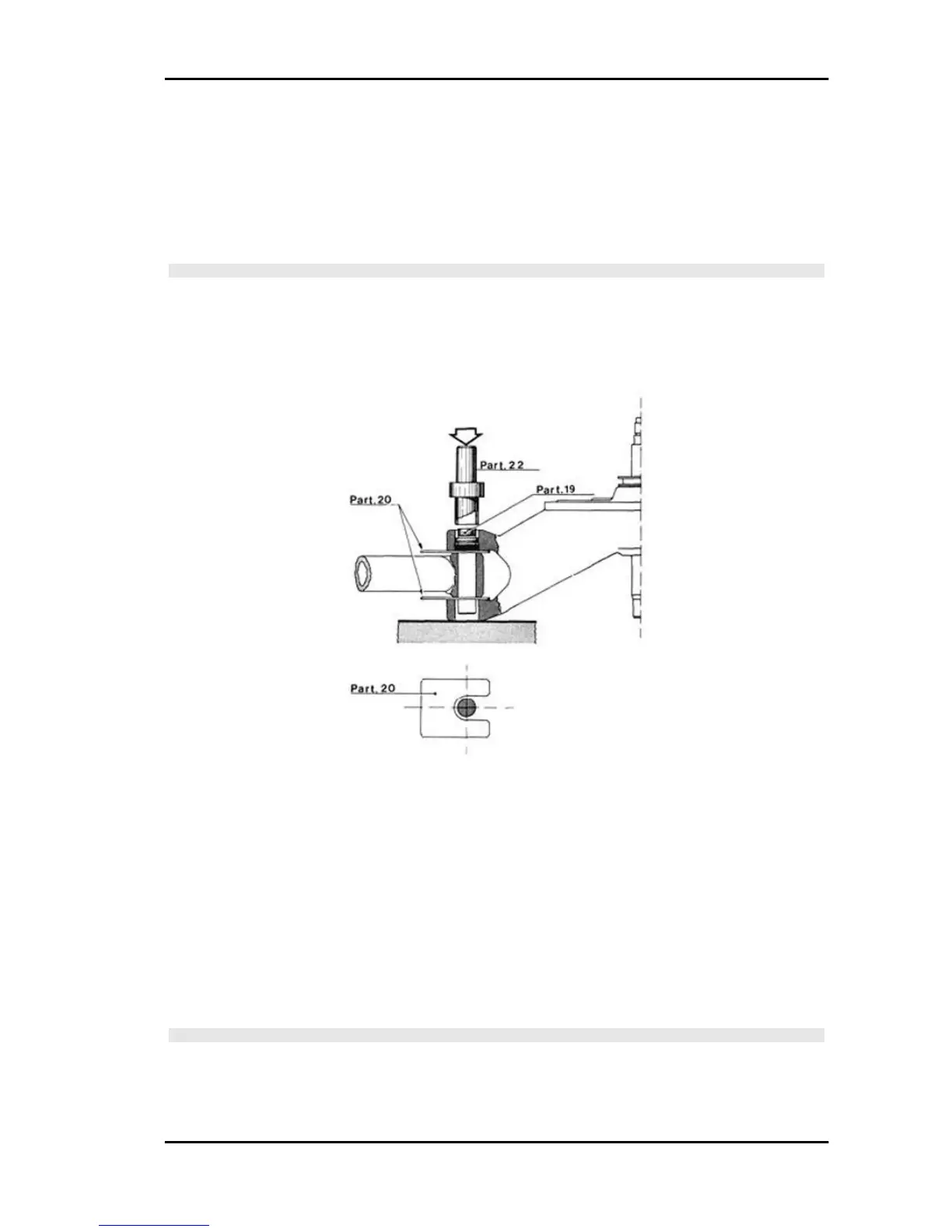

- Once the pin has been assembled, remove the unit from the tool and, with light use of the mallet, fit

the two spacers component 20.

WARNING

THE ASSEMBLY OF THE SPACERS MUST BE CARRIED OUT WHILE MAKING SURE TO KEEP

THE CONCENTRICITY AND DISTANCE WITH RESPECT TO THE PIN; INDEED AN INCORRECT

POSITIONING OF THEM (INDENT OF COMPONENT 20 IN CONTACT WITH THE PIN) WOULD NOT

PERMIT THE PASSAGE OF THE SEAL RINGS IN THE ASSEMBLY PHASE.

Manually fit the two sealing rings that have been dipped in lube oil to the pin, until the top end of the

pin, on which component 19 will be positioned, is left free; then through the use of comp. 22 push the

seal rings with light mallet blows, until reaching the stop of the comp. 22 on comp. 19.

2nd SEAL RING - FITTING

- Repeat the above procedure working on the side opposite the one shown in the figure, in order to fit

the other seal ring.

ROLLER BUSHINGS COMPLETE WITH WEDGE WASHERS - FITTING

Fit on the pin, by hand, the roller bushing complete with the wedge washer.

WARNING

BEFORE PROCEEDING TO THIS PRE-FITTING, THE ROLLER BUSHINGS (AFTER HAVING BEEN

WASHED IN PURE PETROL OR NEUTRAL PETROLEUM TO REMOVE THE RUST PREVENTER)

MUST BE HALF FILLED WITH THE SPECIFIC GREASE.

Recommended products

APE TM Benzina Suspensions

SS - 123

Loading...

Loading...