2 Move the control lever to ON position (see photo on page 16)

MC operates the pump.

3 Operate the nozzle lever to start the dispensing operation

MC indicates the dispensed quantity.

4 After terminating the dispensing operation, rewind the hose around the hose carrier,

move the control lever to OFF position and put the nozzle back in its seat.

MC stops the pump.

ROUTINE MAINTENANCEM

CUBE MC has been designed so as to require minimum maintenance. For utmost station

efficiency and safety, the following inspection and ROUTINE maintenance operations should

however be regularly performed.

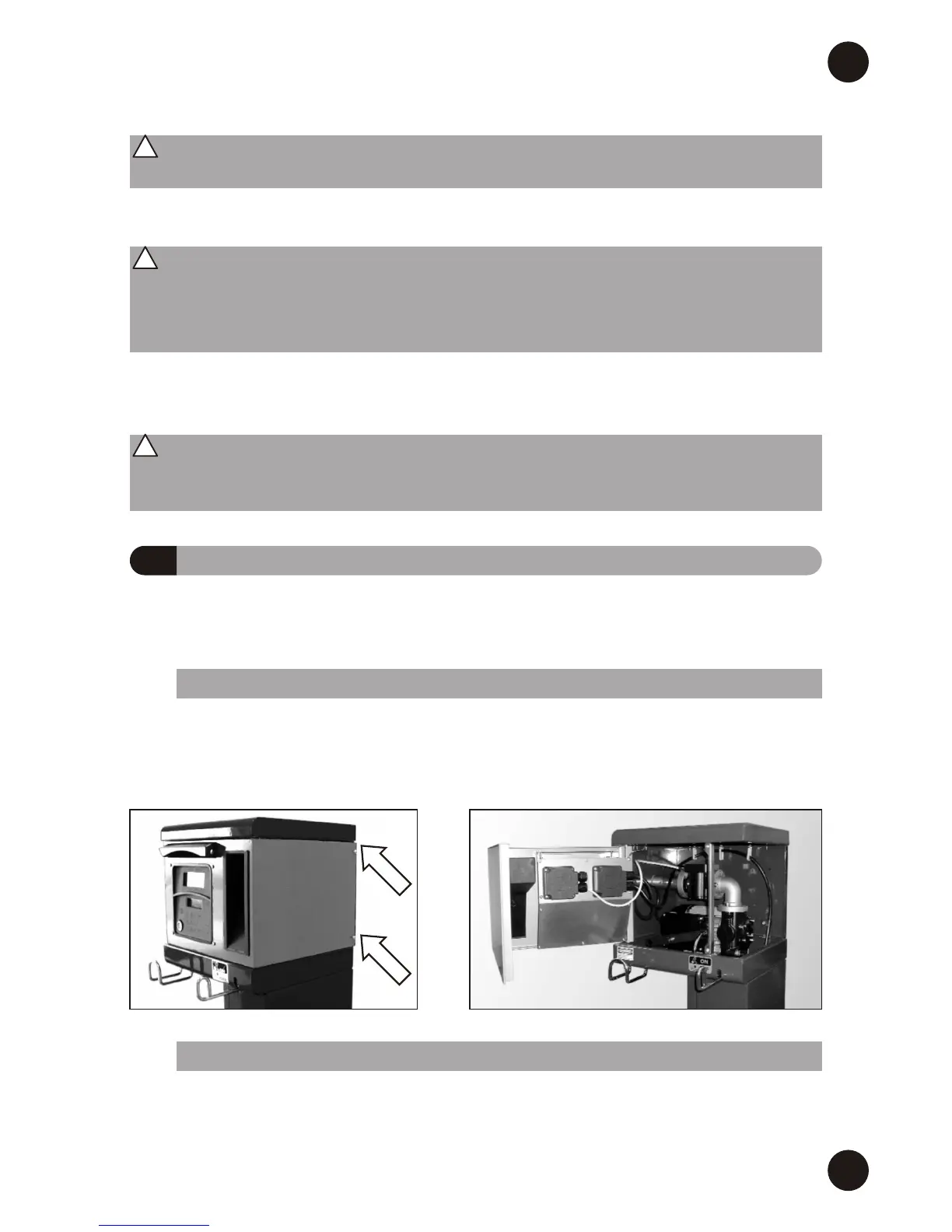

Check the pump, the pipes and other internal components of the station and keep them clean.

Make sure there are no leaks in the flanged or threaded connections and that the hoses are

in perfect condition (not damaged) - refer to the Panther M0042 and K600, M0147 manual.

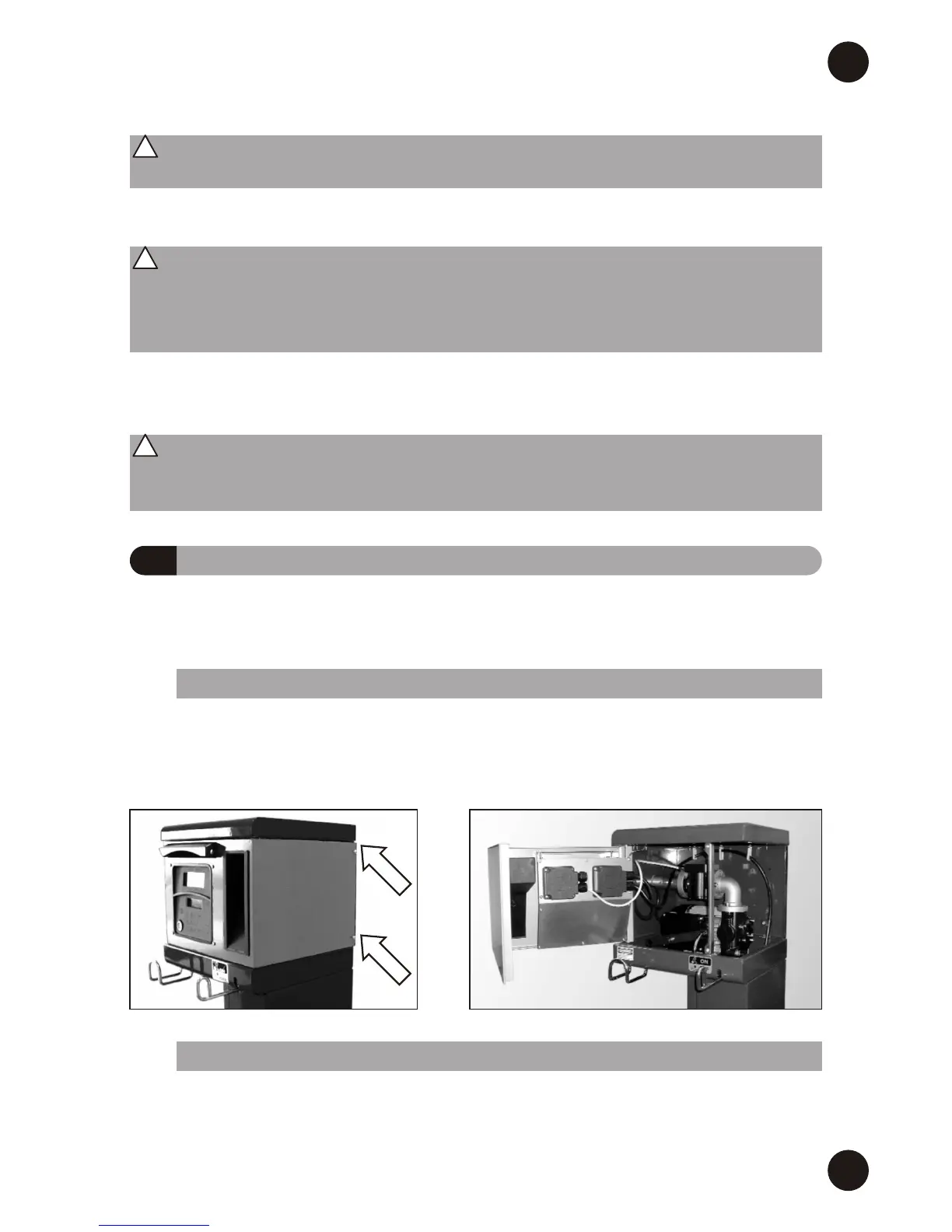

- Lower the display cover

- Loosen the 2 screws on the right side (marked by the arrows)

- Open the inspection side of the CUBE MC

- To reclose it, perform these steps in reverse order.

M1 OPENING AND CLOSING THE CUBE MC

M2 PUMP AND PIPES

EN

19

(Translated from Italian)

If there is a power cut or the pump stops, the operator has to put the nozzle back in the

unit seat. Remember that the nozzle can be opened only when the spout is in the tank.

! ATTENTION

The dispensing operation can be interrupted as required. If the interruption continues

for over a certain time (which can be set as required by the station manager during MC

configuration) the pump is stopped and disabled. To continue dispensing fuel, the

various steps will have to be repeated starting from no. 1.

! ATTENTION

Never operate the nozzle lever before placing this in the fuel container

! ATTENTION

Loading...

Loading...