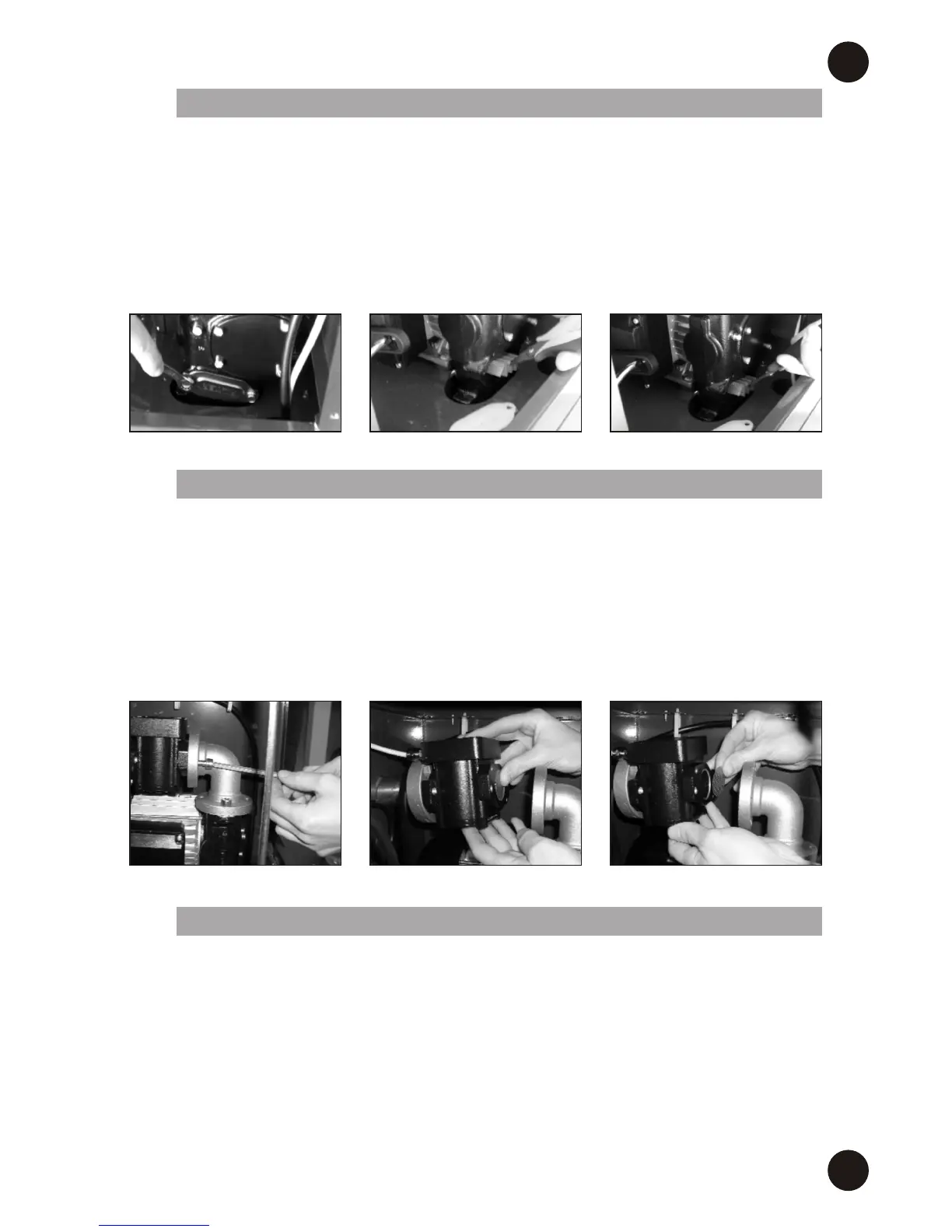

M5.2 PUMP FILTER

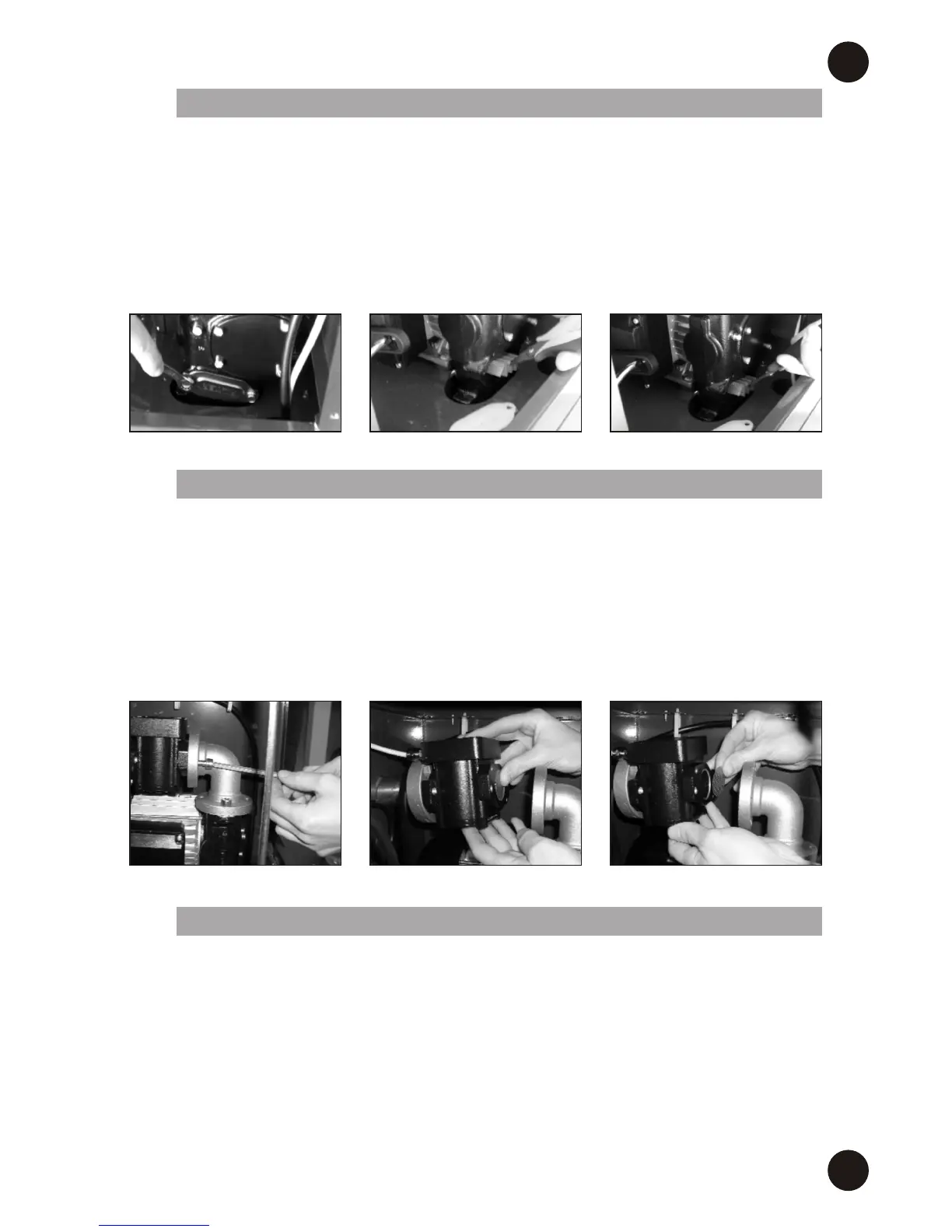

M5.3 PULSER FILTER

M6 PULSER

This is fitted in the pump body, as a standard PANTHER pump fitting.

To inspect and clean it:

1 Loosen the two filter cover screws and take the cover off.

2 Take out the mesh filter with the aid of a pair of pliers.

3 If the filter needs cleaning, wash and blow it.

4 Put the filter carefully back in its housing in the pump body, making sure it does not protrude

from the cover housing.

5 Check and clean the flat seal, reposition the cover and tighten the screws.

The pulser filter represents a further protection against the risk of foreign bodies entering the

oval-gear pulser.

Because this filter is fitted downstream of the pump suction filter, it does not require regular

inspection and cleaning.

Should the need arise however and/or in case of special maintenance, it can be cleaned as

described in the PULSER MANUAL, after removing the roof of CUBE MC (if necessary) by

means of its relevant upper screws (see exploded view, pos.14).

The meter / pulser is a carefully-made and assembled high-precision measuring instrument.

It normally requires no routine maintenance.

CALIBRATION, normally done during station installation, can be repeated whenever accuracy

checks, to be performed every 3/6 months, show the need.

CALIBRATION is done electronically by means of the MC control system, and does not require

any adjustments to be made to the pulser.

For all details, refer to the K600, M0147 meter manual.

EN

21

(Translated from Italian)

Loading...

Loading...