?

16 /20

Use, maintenance and calibration

M0171G

8.2.3 DIRECT MODIFICATION OF K FACTOR

If normal Meter operation shows a mean percentage error, this can be corrected by applying to the cur-

rently used calibration factor a correction of the same percentage. In this case, the percentage correction

of the USER K FACTOR must be calculated by the operator in the following way

New Cal. Factor = Old Cal. Factor * ( 100 - E% / 100 )

EXAMPLE:

Error percentage found: E% - 0.9 %

CURRENT calibration factor: 1.000

New USER K FACTOR: 1.000 * [(100 – ( - 0.9))/100] = 1.000 * [(100 + 0.9)/100] = 1.009

If the Meter indicates less than the real dispensed value (negative error) the new calibration factor must be

higher than the old one as shown in the example. The opposite applies if the Meter shows more than the

real dispensed value (positive error).

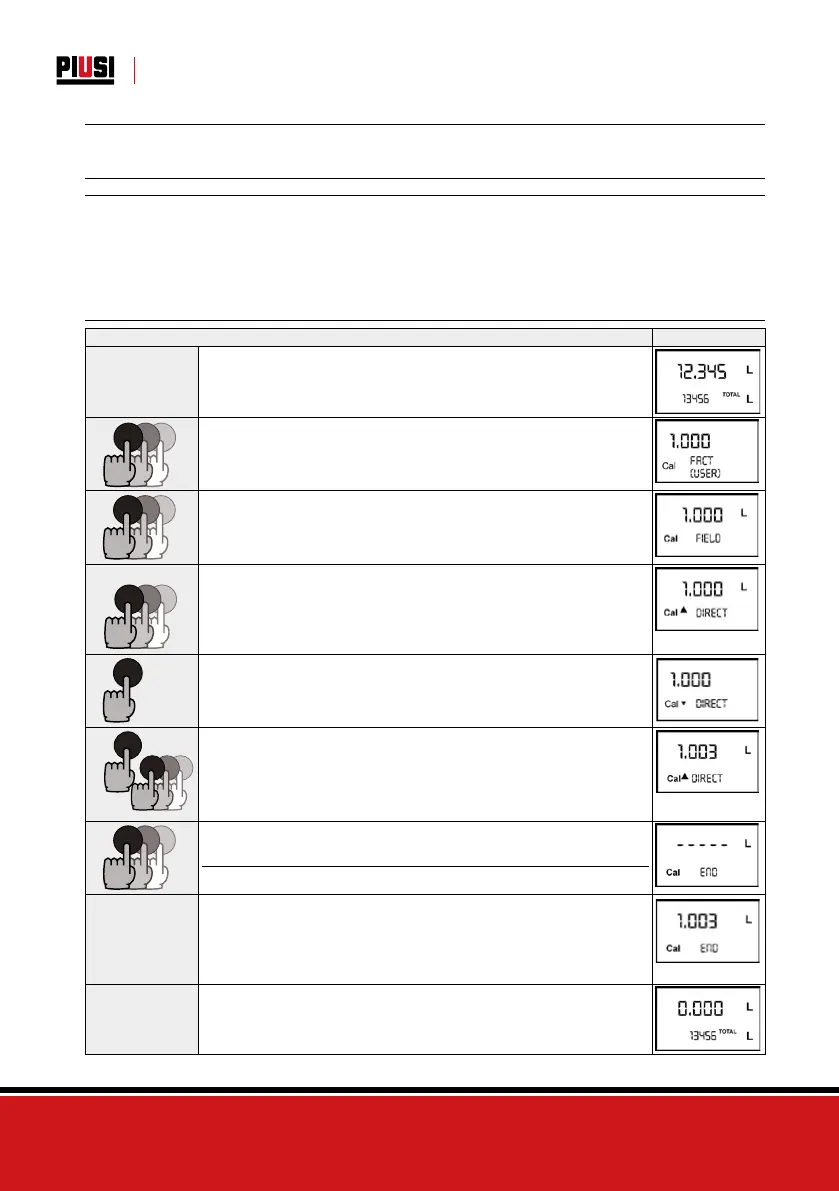

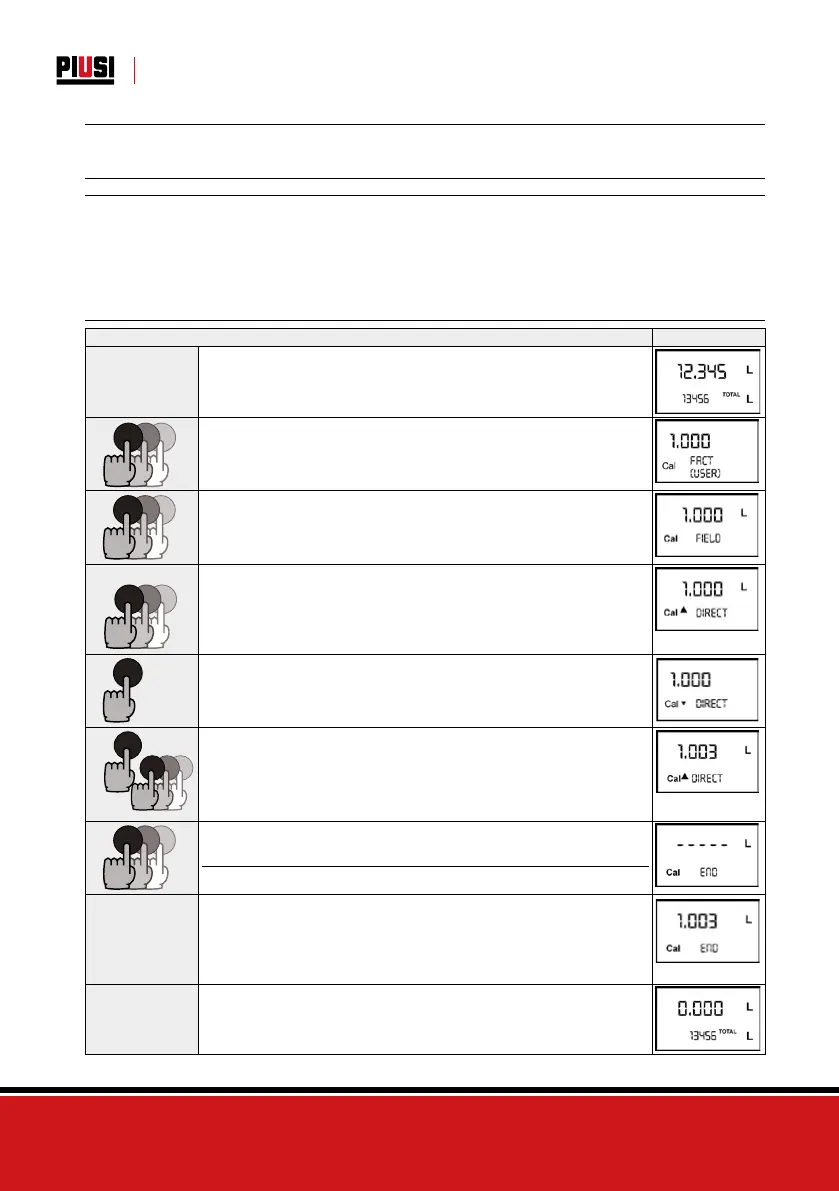

ACTION DISPLAY

1

NONE

METER in Standby.

2

CALCAL

CAL

LONG CAL KEY KEYING

Meter enters calibration mode, shows “CAL” and displays the calibration factor

being used instead of the partial. The words “Fact” and “User” indicate which of the

two factors (factory or user) is currently being used.

3

RESET

RESET

RESET

LONG RESET KEY KEYING

The Meter shows “CAL” and the zero partial total.

Meter is ready to perform in-field calibration by dispensing – see previous

paragraph.

4

RESET

RESET

RESET

LONG RESET KEY KEYING

We now go on to Direct change of the calibration factor: the word “Direct” appears

together with the Currently Used calibration factor. In the boom le part of the

display, an arrow appears (upwards or downwards) defining the direction (increase

or decrease) of change of the displayed value when subsequent operations 5 or 6

are performed.

5

RESET

SHORT RESET KEY KEYING

Changes the direction of the arrow. The operation can be repeated to alternate

the direction of the arrow.

6

CALCAL

CAL

CAL

SHORT/LONG CAL KEY KEYING

The indicated value changes in the direction indicated by the arrow

- one unit for every short CAL key keying

- continually if the CAL key is kept pressed. The speed increase rises by keeping

the key pressed. If the desired value is exceeded, repeat the operations from point

(5).

7

RESET

RESET

RESET

LONG RESET KEY KEYING

The Meter is informed that the calibration procedure is finished.

Before performing this operation, make sure the INDICATED value is that required.

8

NO OPERATION

At the end of the calculation, the new USER K FACTOR is shown for a few seconds,

aer which the restart cycle is repeated to finally achieve standby condition.

IMPORTANT: From now on, the indicated factor will become the calibration

factor used by the Meter and will continue to remain such even aer a baery

change

9

NO OPERATION

The Meter stores the new work calibration factor and is ready to begin dispensing,

using the USER K FACTOR that has just been changed.

Loading...

Loading...