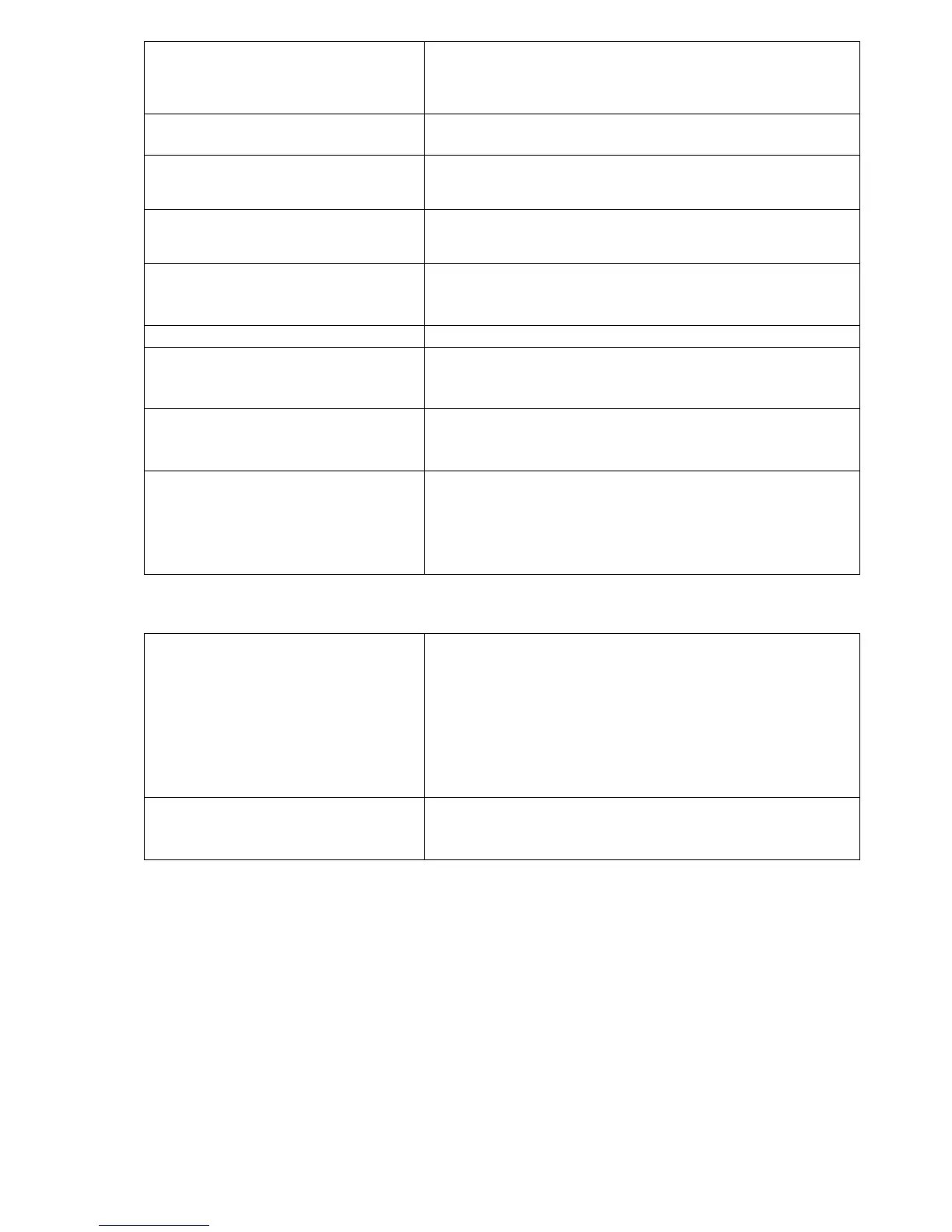

This parameter switches ON and OFF the boiler return

protection function performed using mixing valve with

electric servo. Note: do not switch on this function if the

valve is not provided with electric servo!

Boiler return temperature below the value at which

electric servo closes mixing valve.

Electric servo returns to normal operation at the return

temperature ≥ min.return temperature + Return temp.

hyst.

It is % opening of mixing valve during active return

protection function. Note: the valve closes with accuracy

of +/-1%.

The temperature of retort boiler at which reserve boiler

(e.g. gas fired boiler) will be OFF is set using this

parameter. Details - see sec. 11.12

Parameter used to rough calculation of boiler output

(displayed in INFO window) and of fuel level and it has

no effect on control of combustion process [kg/h].

Parameter used to rough calculation of boiler output; it

has no effect on control of combustion process. Its value

for hard coal amounts to approx. 6.5 [kWh/kg]

Parameter used to calculate fuel level [kg]. Note:

Change and confirmation of the value using the knob

replaces previously completed fuel level calibration with

calculation of fuel level using Tank Capacity and Feeder

Efficiency parameters.

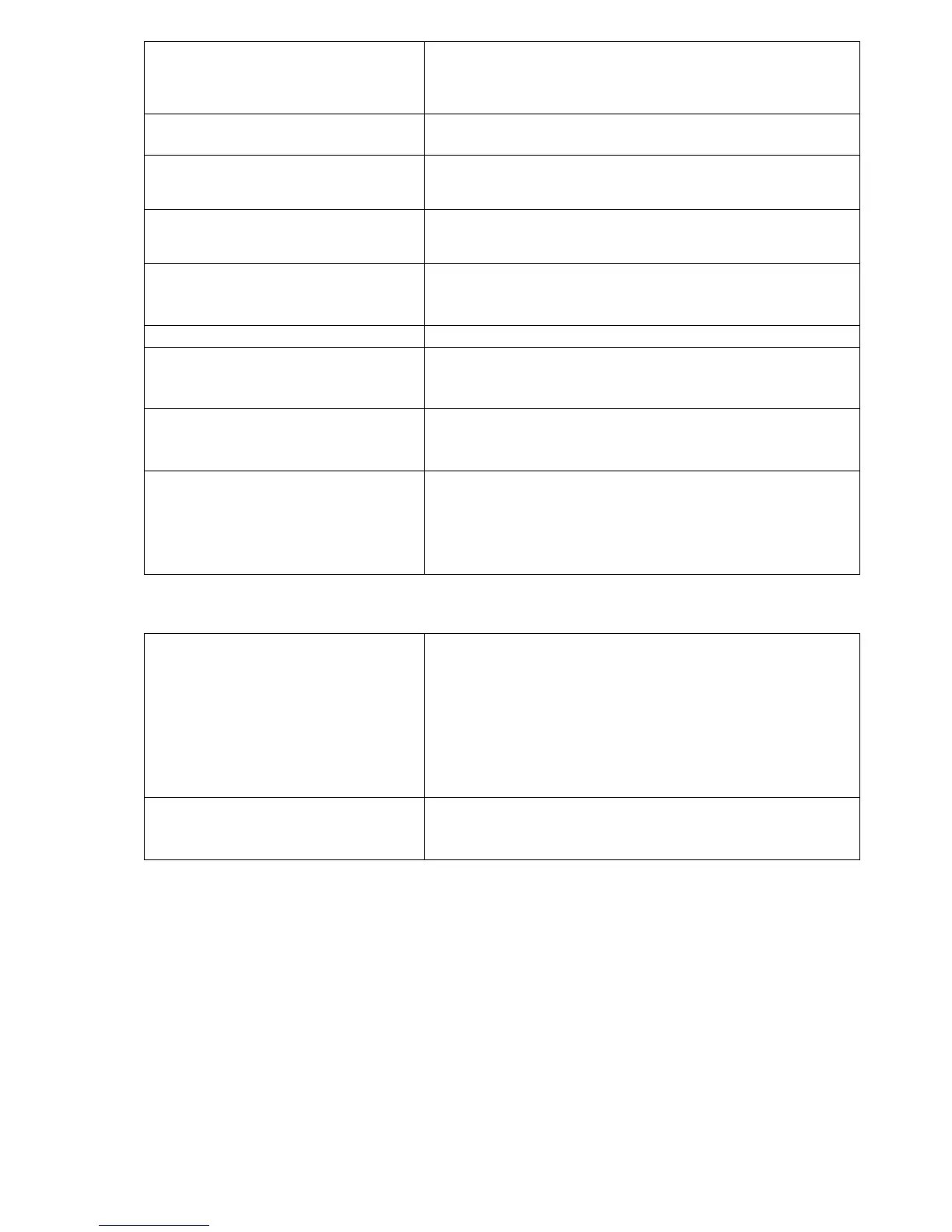

13 SERVIS SETTINGS OF PUMPS

CH pump standstill at HUW

supply

Parameter available upon connection of HUW sensor. Too

long time of HUW container filling at active HUW priority

may lead to excessive cooling down of CH system

because boiler pump (CH pump) is switched off at this

time. Parameter of CH pump standstill time during HUW

filling prevents it by periodic CH pump switch-on during

HUW container filling. After that time, CH pump will

switch on for a fixed time set at 30s.

This parameter is available upon connection of HUW

sensor and prevents the user to set too low preset HUW

temperature.

Loading...

Loading...