PH/PHX-2 Manual

40

5. Cavitations

Cavitations occur when the Metering Pump (B or C, page 14) requires a larger volume of

material than the supply system (Transfer Pump) can furnish. This creates a "void" of

material in the Metering Pump. The most common causes of cavitations are:

a) Material temperature too low causing increased material viscosity resulting in the

inability of the Transfer Pump to maintain sufficient supply to the Metering Pump.

This is most common with today's blowing agents. Ensure the material

temperature in the drums is no lower than the material suppliers' recommendation.

b) Failure to vent the material drum while drawing material out with the Transfer Pump

causes a vacuum and cavitations in the Transfer Pump. Ensure the drum is vented

to the atmosphere or a Desiccated Air Dyer Kit is installed as recommended by the

material supplier.

c) Insufficient air volume for Transfer Pump or a partially closed Transfer Pump Air

Valve will limit the ability of the Transfer Pump to operate at its maximum

capability.

d) Inlet Material Screen (M, page 14) obstructed (See MAINTENANCE section,

page 46).

e) Metering Pump Inlet Ball does not seat properly allowing material to flow back into

the Material Delivery Hose when the Metering Pump is on the "Discharge" stroke.

This causes the volume of material on that Metering Pump to be less on the

discharge stroke resulting in intermittent off-ratio material and Pressure Gauge

fluctuation.

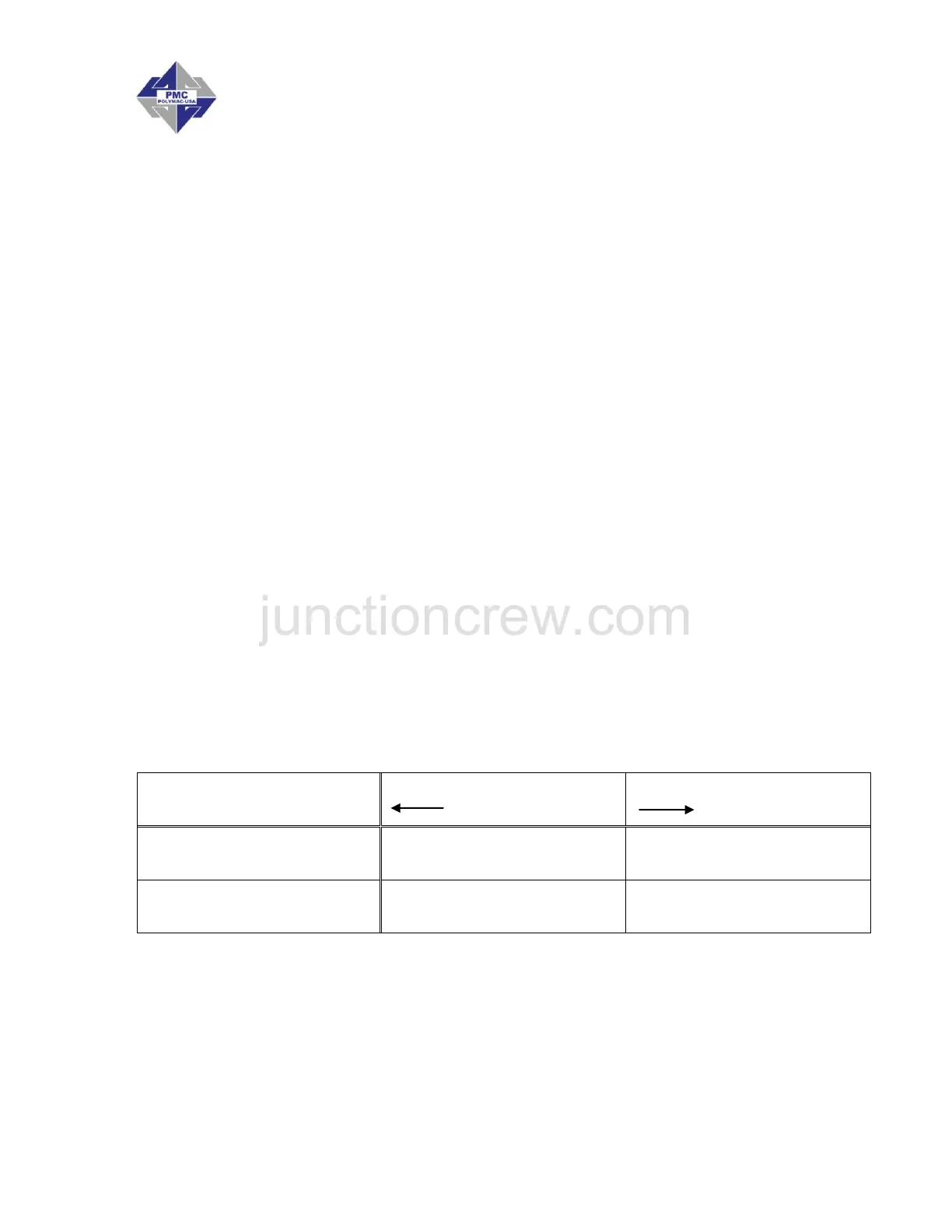

6. Pressure Loss: Discharge/Inlet Ball

Simultaneous observation of the material Pressure Gauge (E, F, page 14) and

Direction Indicator Light (Q, page 15) is necessary to determine which direction the

Metering Pump fails to maintain pressure. Refer to the chart to determine problem:

Directional

Indicator Light ON

Directional

Indicator Light ON

Iso Inlet Ball does not seat

properly

Iso Discharge Ball does not

seat properly

Poly Pressure Gauge

FALLS

Poly Discharge Ball does

not seat properly

Poly Inlet Ball does not

seat properly

In most cases the cause of a leaking Inlet/Discharge Ball is foreign material preventing

the Ball from seating properly. If the above steps do not resolve the problem, replace

the appropriate Ball, Ball Seat.

For service see MAINTENANCE/Metering Pump Line, page 48.

Loading...

Loading...