ENGINE

2.14

ENGINE INSPECTION PROCEDURES, CONT.

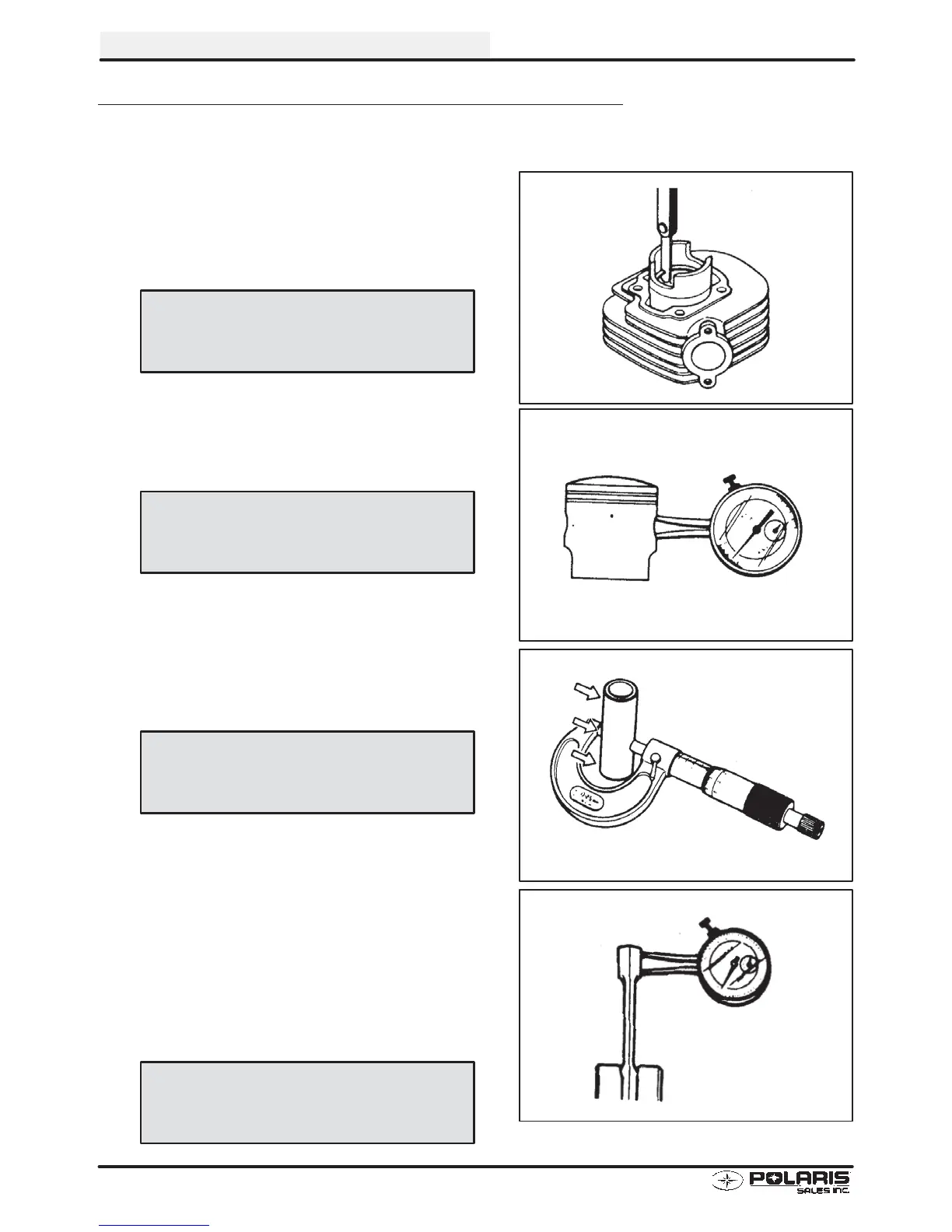

Piston Ring Installed Gap

1. Position piston ring 1/2

″

(1.3 cm) from the top of the

cylinder using the piston to push it squarely into

place. Measure installed gap with a feeler gauge at

both the top and bottom of the cylinder. Replace

rings if the installed end gap exceeds the service

limit.

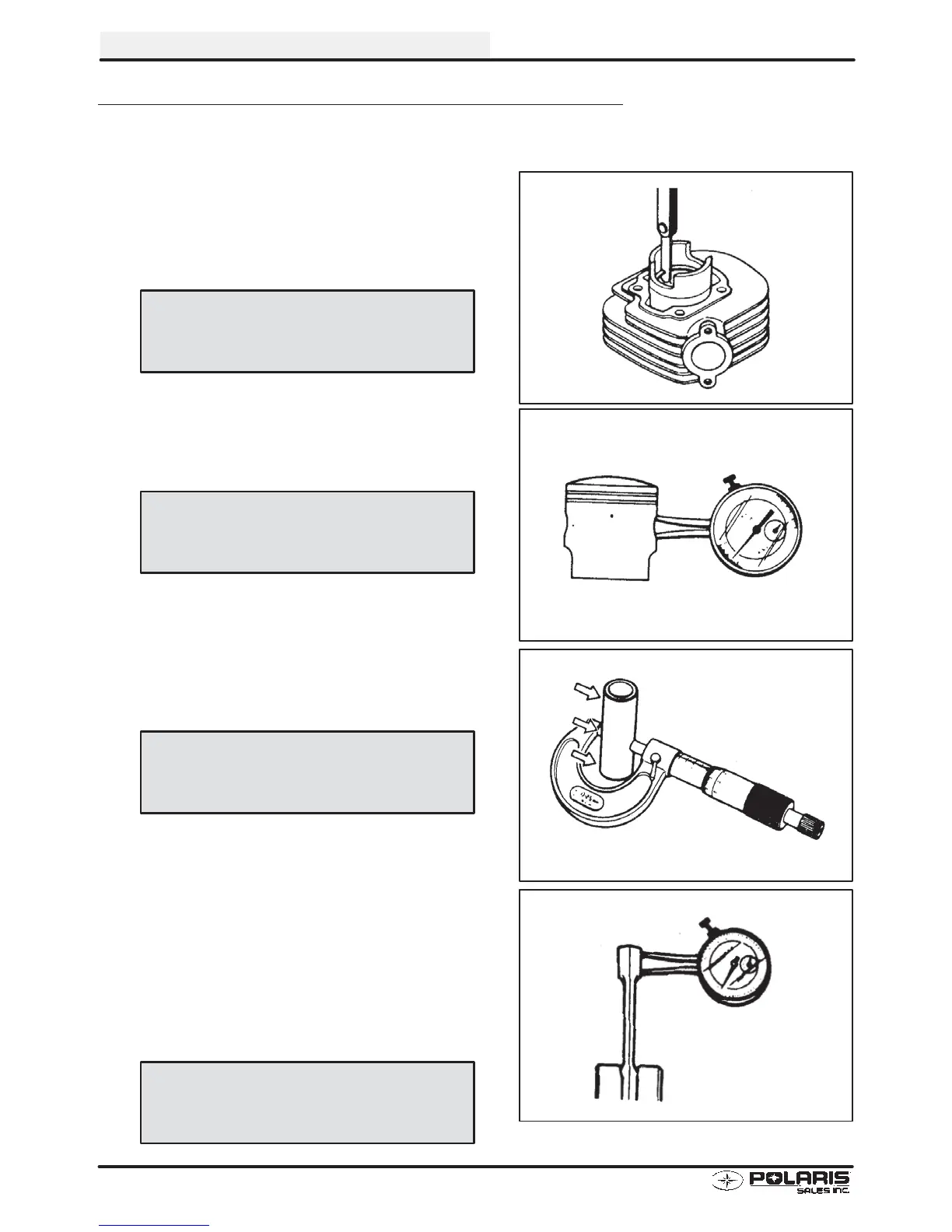

PIston Pin Hole Inspection

2. Using a telescoping gauge or similar bore gauge,

measure the inside diameter of the piston pin hole

on both sides of the piston. Replace if diameter

exceeds .395″ (10.03 mm)

PIston Pin Inspection

3. Inspect the surface of the piston pin for damage.

Measure the diameter of the piston pin in three

areas with a micrometer. The service limit for the

piston pin is .393″ (9.980 mm).

Connecting Rod Inspection

4. Inspect the inner surface of the small end of the

connecting rod for wear or damage. Oil and install

needle bearing and pin in connecting rod. Rotate

pin slowly and check for rough spots or any

resistance to movement. Replace both pin and

bearing if there is any resistance to rotation.

Measure the inner diameter of the small end of the

connecting rod. The service limit is .553″ (14.04

mm.)

Piston Ring Installed Gap

Service Limit:

.030I (0.75 mm)

Piston Pin Hole

Service Limit:

.395I (10.03 mm)

Piston Pin

Service Limit:

.393I (9.980 mm)

Connecting Rod Small End

Service Limit

.553I (14.04 mm)

Loading...

Loading...