ENGINE

2.15

ENGINE INSPECTION PROCEDURES, CONT.

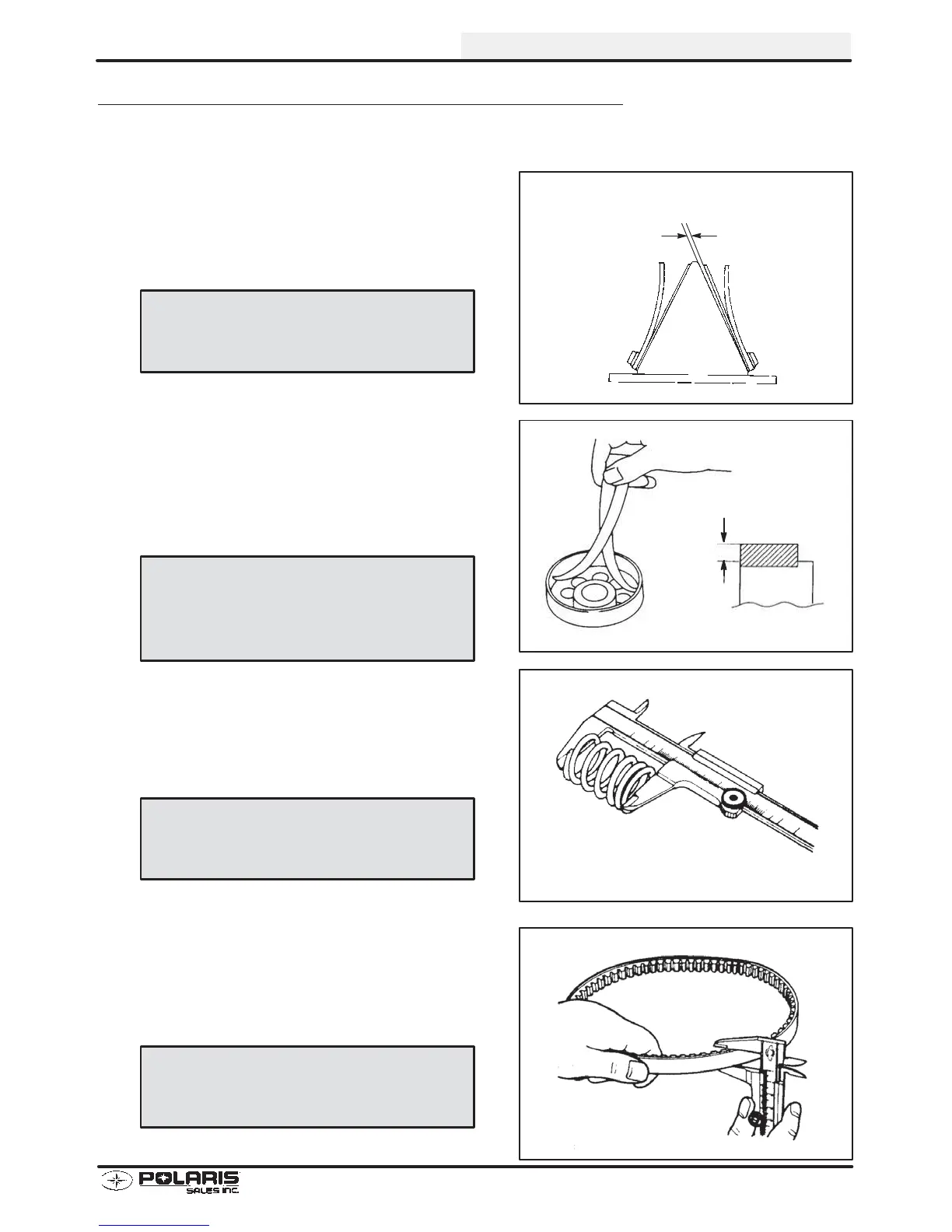

Reed Valve Inspection

1. Measure the air gap between fiber reed and reed

block as shown. The air gap should not exceed

.015

″

(.40 mm) If clearance is excessive DO NOT

attempt to reverse the reeds to reduce the air gap.

Always replace them if damaged.

Check each fiber

reed for stress marks or missing material.

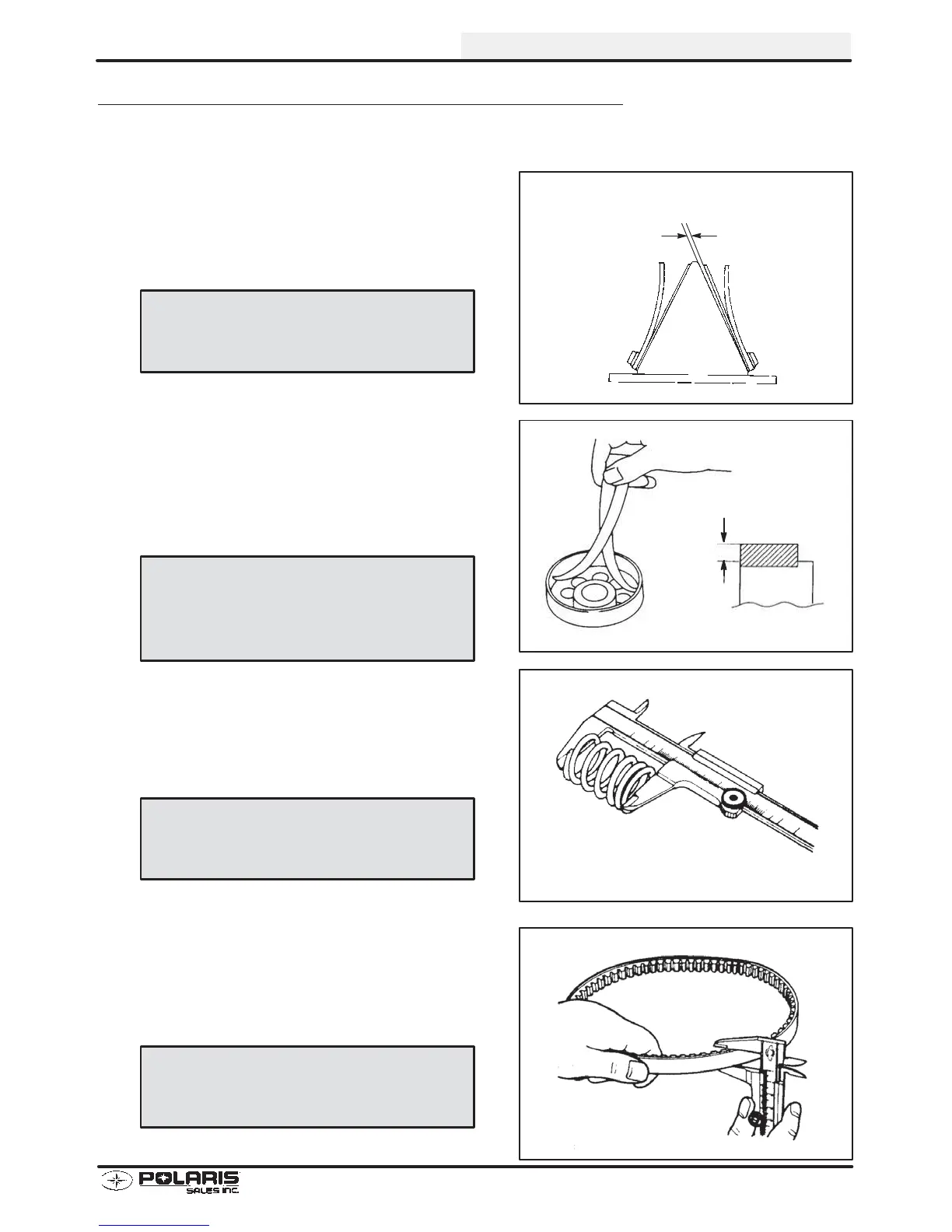

Clutch Cover and Brake Lining

2. Inspect the condition of the clutch cover. Measure

the inside diameter of the cover using a caliper. The

inner diameter service limit is 4.43″ (112.5 mm).

Inspect the condition and diameter of the brake

lining. The service limit of the lining is .039″ (1.0

mm). If either of these measurements exceeds the

limit, replace the clutch cover.

Compression Spring

3. Use a vernier caliper to inspect the length of the

compression spring. With the spring at full

extension, the measurement should be no less than

2.74″ (69.7 mm). If out of specification, replace

spring.

Belt Inspection

4. Inspect the surface of the drive belt for uneven wear

or grease deposits. Using a vernier caliper,

measure the width of the belt. The service limit of

the belt is .626″ (15.9 mm). If the width of the belt is

less than the service limit, or if the belt is worn,

glazed or hourglassed, replace.

Reed Pedal

Clearance .015

″

(.38 mm) max.

Exaggerated

for illustration

Reed Valve Air Gap

Service Limit:

.015I (0.4 mm)

.039″ (1.0 mm)

Clutch Cover Inner Diameter

Service Limit: 4.43I (112.5 mm)

Brake Lining

Service Limit: .039″ (1.0 mm)

Compression Spring

Service Limit:

2.74I (69.7 mm)

Drive Belt Width

Service Limit

.626I (15.9 mm)

Loading...

Loading...