3.39

ENGINE

3

Valve Inspection

1. Remove all carbon from valve with a soft wire wheel.

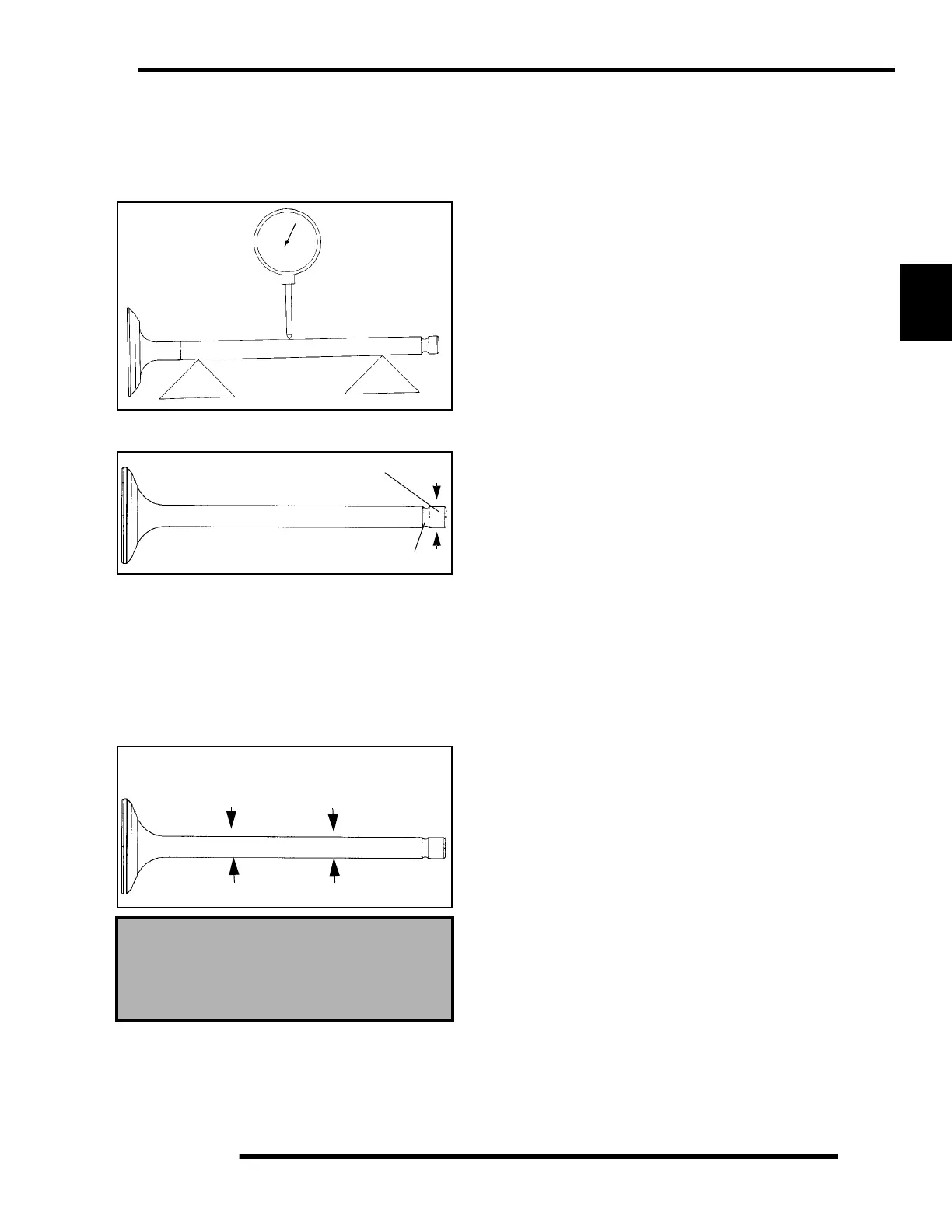

2. Check valve face for runout, pitting, and burned spots. To

check for bent valve stems, mount the valve in “V” blocks

and use a dial indicator.

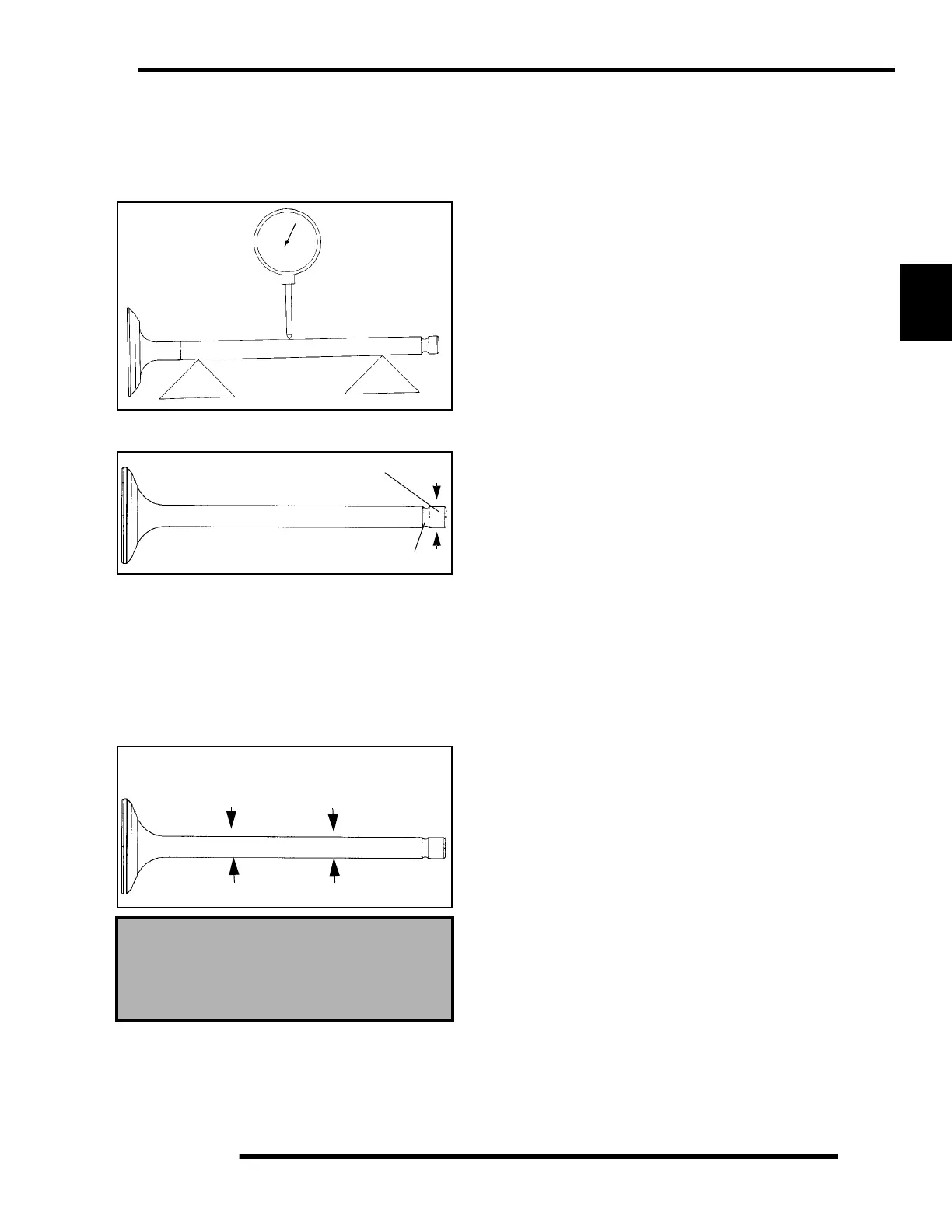

3. Check end of valve stem for flaring, pitting, wear or damage

(A).

4. Inspect split keeper groove for wear or flaring of the keeper

seat area (B).

NOTE: The valves cannot be re–faced or end

ground. Valves must be replaced if worn, bent, or

damaged.

5. Measure diameter of valve stem with a micrometer in three

places and in two different directions (six measurements

total). Compare to specifications.

Valve Stem Diameter:

Intake: .2343- .2348

″ (5.950- 5.965 mm)

Exhaust: .2341- .2346

″ (5.945- 5.960 mm)

A

B

Measure valve stem in

several places

Loading...

Loading...