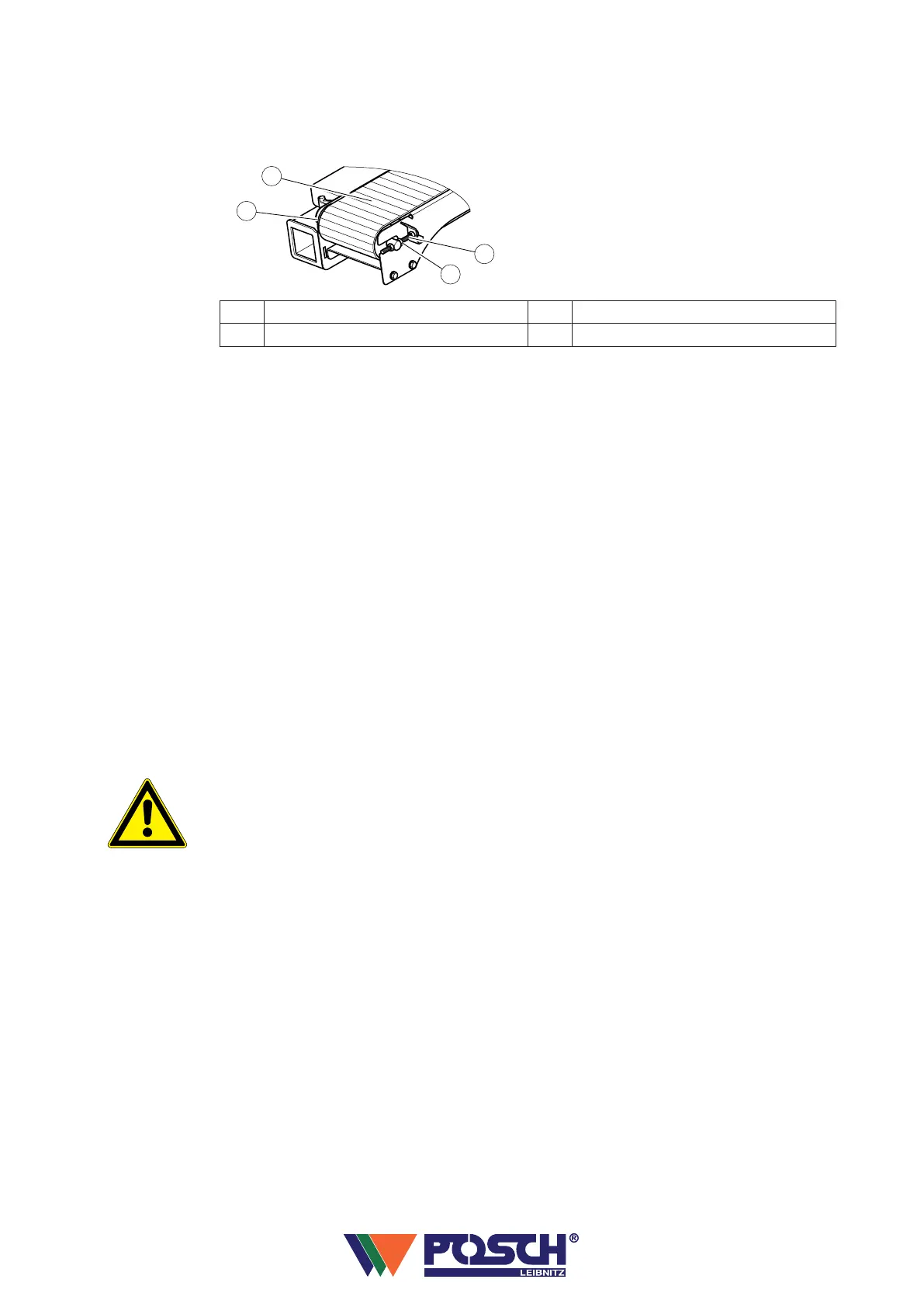

Conveyor belt - ensuring the machine is running centrally

1 Conveyor belt 3 Tensioning screw

2 Return drum 4 Lock nut

If the conveyor belt is not running centrally on the drive and/or return drum, it is possible to

adjust the direction of travel.

▪ Loosen the lock nuts on both tensioning screws.

▪ Align the return drum by tightening both tensioning screws evenly.

▪ Lock the lock nuts on both tensioning screws.

Tensioning the belt

The conveyor belt may become slack over time as a result of wear and tear. If this happens,

the belt must be retensioned.

▪ Loosen the lock nuts on both tensioning screws.

▪ Tension the conveyor belt by tightening both tensioning screws evenly.

▪ Tension the conveyor belt sufficiently (underside of belt must not sag).

▪ Lock the lock nuts on both tensioning screws.

Cleaning

Before cleaning work on the machine, it is vital to switch off the drive and secure it so it

cannot be switched on accidentally or started-up by unauthorised persons.

Disconnect the machine from the mains.

▪ In addition, pull out the plug of the device.

▪ Disengage the universal joint shaft on the tractor.

– Before disengaging, turn the manual throttle to minimum.

▪ Remove the universal joint shaft from the tractor.

Clean the machine regularly to ensure proper operation.

Only wash new machines (during the first 3 months) with a sponge.

▪ The paint is not yet completely set, so cleaning with a high pressure cleaner may

damage the finish.

10.7.2

10.7.3

10.8

Maintenance

41

Loading...

Loading...