Maintenance

Before maintenance work on the machine, it is vital to switch off the drive and secure it so

it cannot be switched on accidentally or started-up by unauthorised persons.

Disconnect the machine from the mains.

▪ In addition, pull out the plug of the device.

▪ Disengage the universal joint shaft on the tractor.

– Before disengaging, turn the manual throttle to minimum.

▪ Remove the universal joint shaft from the tractor.

Work on electrical equipment must only be carried out by qualified electricians.

Never work without the protective guards in place.

Only use original - POSCH - spare parts.

Lubrication

Dispose of oily and greasy parts and oil residues in accordance with legal regulations.

Lubrication schedule

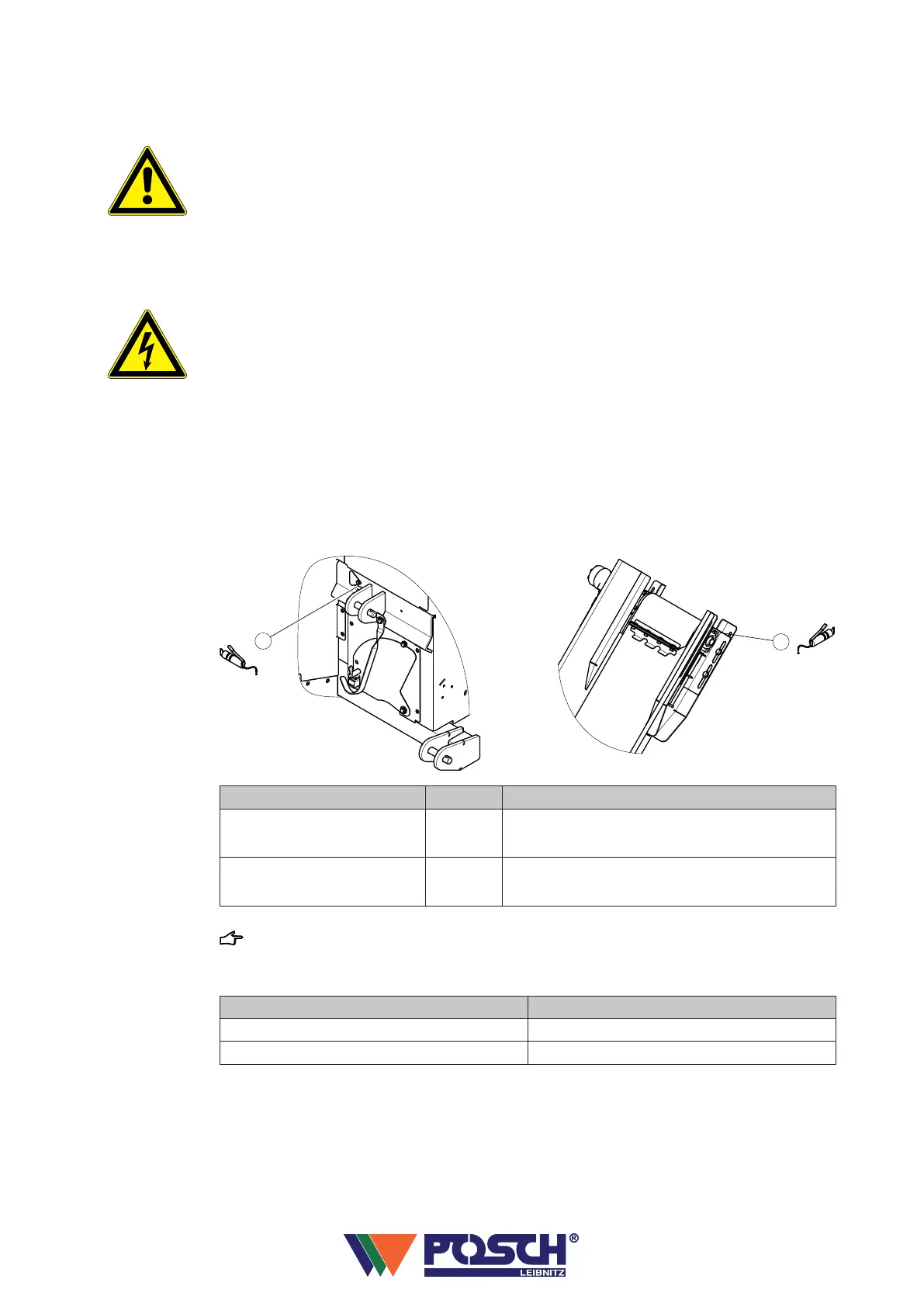

Lubrication intervals Item What/where

Weekly (every 40 operating

hours - or fewer depending

on use)

1 On the back of the central lubrication point - for

the saw shaft

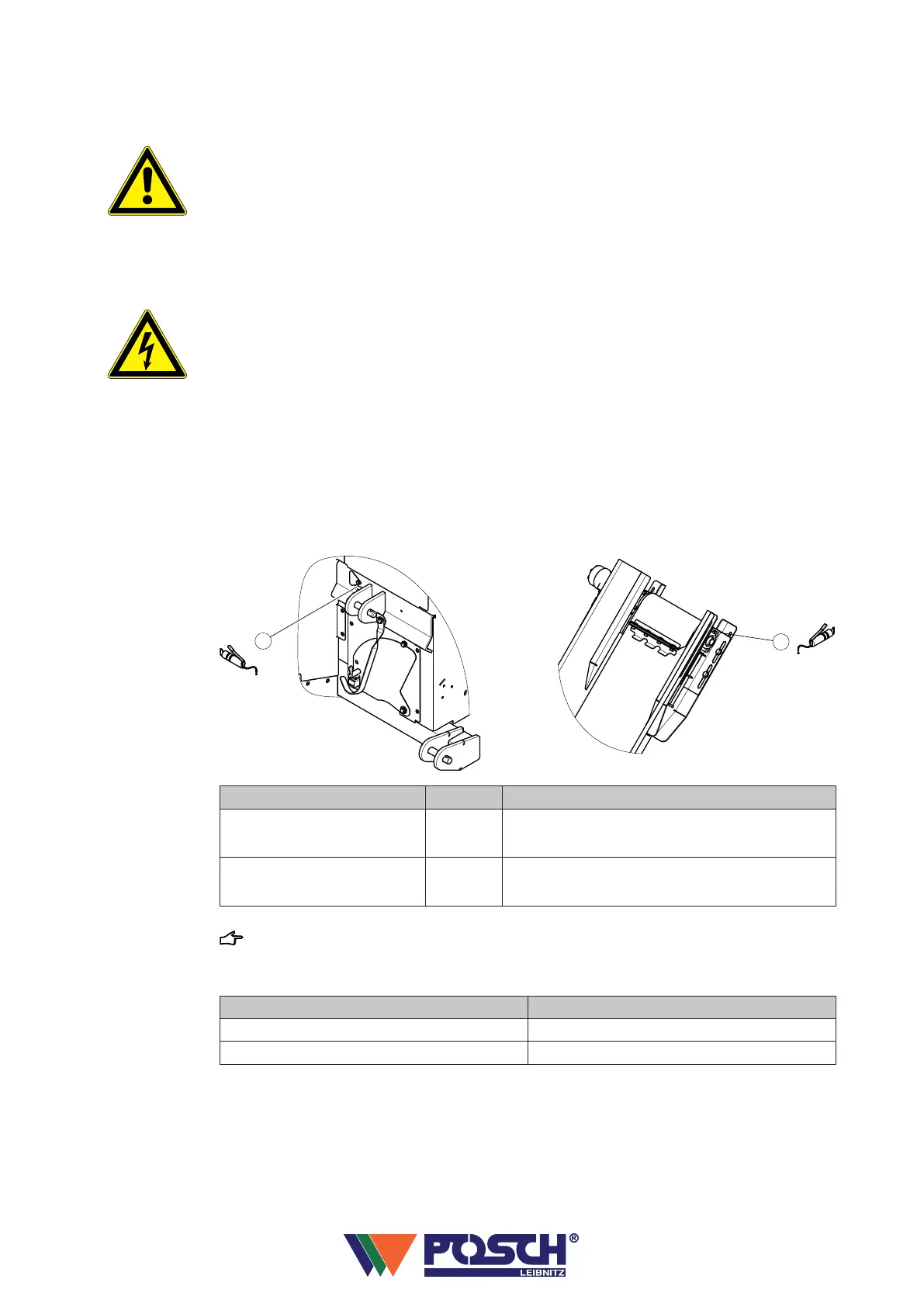

Monthly (every 160

operating hours - or fewer

depending on use)

2 On conveyor belt, top housing bearing

The lubrication points are marked with the lubricate symbol.

Recommended lubricating greases:

Manufacturer

Type

Genol Multi-purpose grease

Fuchs Multi-purpose grease 5028

Oil changing

Old oil must be disposed of in an environment-friendly manner. Find out about the

environmental regulations in your country.

10

10.1

10.1.1

10.2

Maintenance

31

Loading...

Loading...