Maintenance - conveyor belt

Notes regarding the conveyor belt

Check that the belt is running centrally. The belt drive dogs must not move.

▪ If they do, the belt must be corrected so it runs centrally by adjusting the drive pulley or

return drum.

From time to time remove the material that drops down underneath the conveyor belt

to prevent damage to the belt drive dogs.

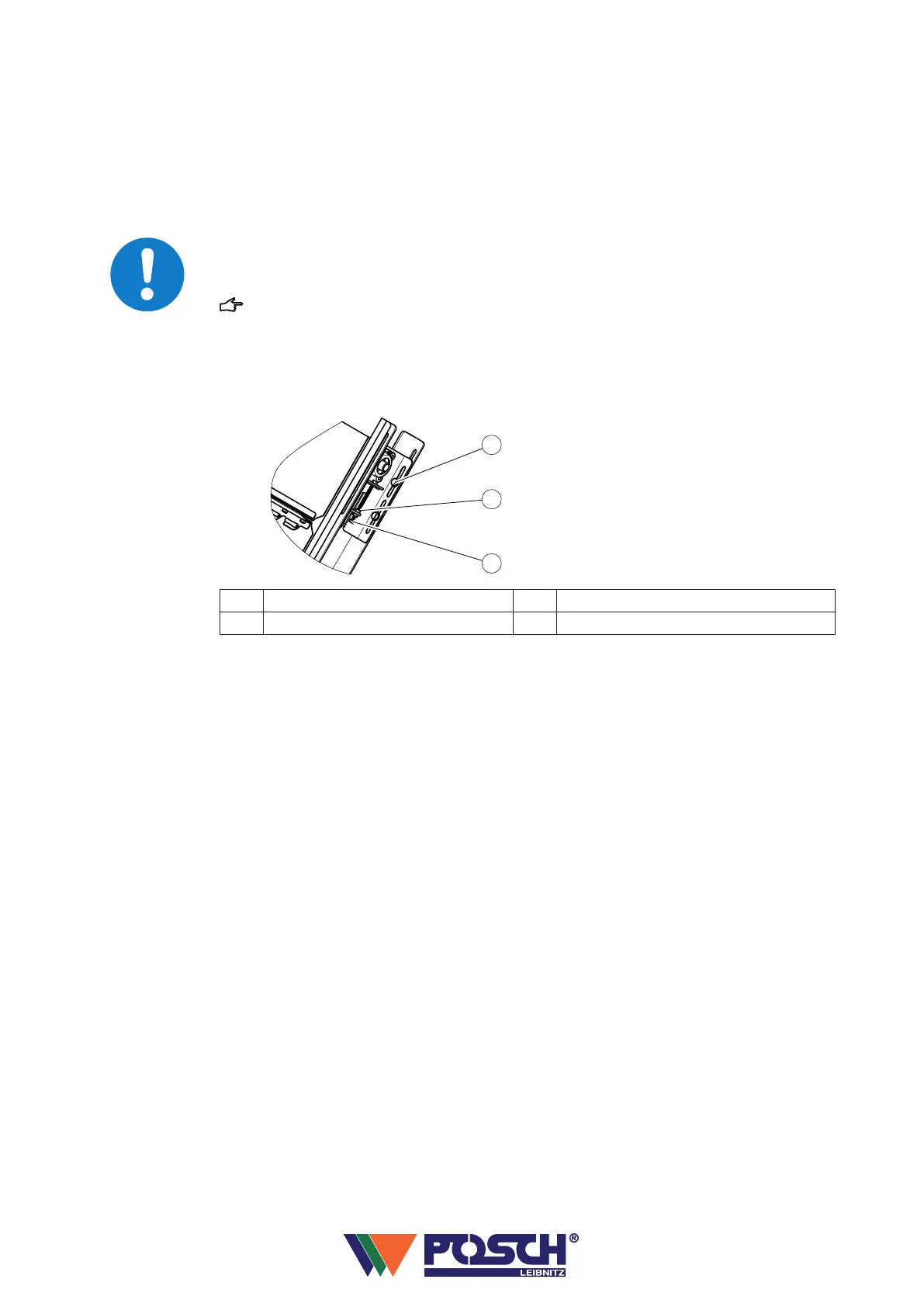

Conveyor belt - set central running

1 Fastening screw 3 Tensioning screw

2 Lock nut

If the conveyor belt is not running centrally on the drive and/or tail pulleys, it is possible to

adjust the direction of travel.

▪ Slightly loosen the fastening screws on each side of the conveyor belt.

▪ Loosen the lock nuts on both tensioning screws.

▪ Align the return drum by tightening both tensioning screws evenly.

▪ Tighten the lock nuts again.

▪ Tighten the fastening screws on both sides.

Tension conveyor belt

The conveyor belt may become slack over time as a result of wear and tear. If this happens,

the belt must be retensioned.

▪ Move the conveyer belt to the working position.

▪ Slightly loosen the fastening screws on each side of the conveyor belt.

▪ Loosen the lock nuts on both tensioning screws.

▪ Tension the upper part of the conveyor belt by tightening both tensioning screws evenly.

▪ After the belt has been tensioned sufficiently, lock the tensioning screws again using

the lock nuts.

▪ Tighten the fastening screws on both sides.

“VolumeControl”

The “VolumeControl” control unit is used to detect the volume of wood that has been

processed.

11.1.5

11.1.5.1

11.1.5.2

11.1.5.3

11.2

Special equipment

44

Loading...

Loading...