8611303 PROCUT45 PLASMA CUTTER V1.1

28 For technical questions call 1-800-665-8685

THE PROCUT45 PLASMA CUTTING GUIDE

The PROCUT45 Plasma Cutting Guide

(SKU 8612590) has two wheels that allow

you to easily cut in straight lines, curves

and circles.

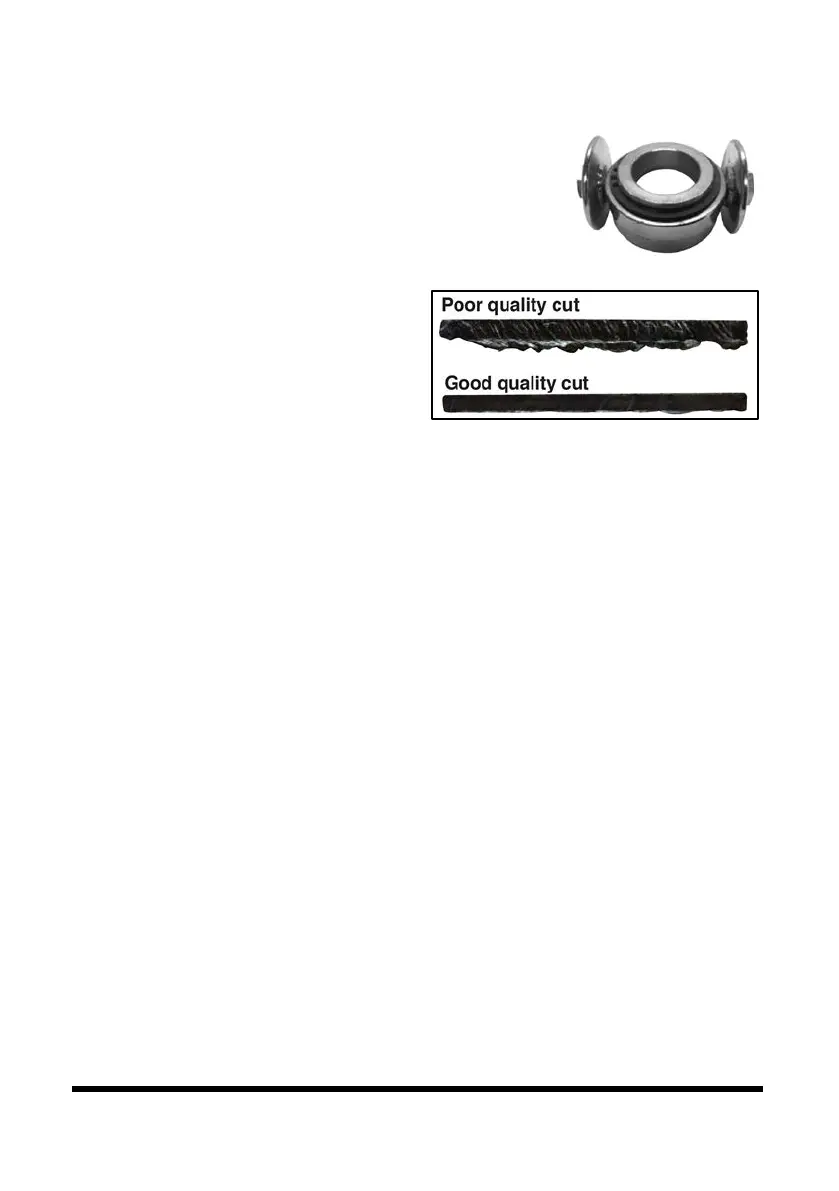

CUT QUALITY

A clean cut depends on

several factors. The best

quality cut will be produced

when all these variables are set

correctly for the material

thickness and type of material

being cut.

The standard rule of thumb is thicker materials require more

amperage.

Set the machine to full output and vary your travel speed with

thick material. Thin material requires lower amperage and a

lower-amperage tip to maintain a narrow kerf. The kerf is the

width of the cut material that is removed during cutting.

Amperage and speed are critical to producing a good quality

cut. Moving faster across the metal (especially on aluminum)

will result in a cleaner cut (Fig. 12).

Visually follow the arc coming out from the bottom of the cut

to determine if you're going too fast or too slow.

• The arc exits the material at a slight angle, away from the

direction of travel, when the speed is correct.

• An arc exiting straight down means you're going too slow.

You will have an unnecessary buildup of dross or slag.

• An arc that sprays across the material’s surface without

cutting all the way through means you’re going too fast.

Loading...

Loading...